Abstract

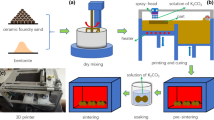

A new water-soluble calcia-based ceramic core of using epoxy resin binder was developed for investment casting by aqueous gel casting. The influences of dispersant addition and solid loading on the rheological property of the slurries were investigated. The low-shrinkage and high-strength ceramic body was obtained by adjusting binder addition and solid loading. The water-soluble behavior of the calcia-based ceramic core and its solution mechanism were studied. The results show that the 48 vol% slurry composing of 6 wt% dispersant content, 16 wt% binder content, and 20 wt% hardener content can prepare a stable and fluidic slurry, and the bending strength of the dried green body is 29.5 ± 1.4 MPa, the linear shrinkage is 3.62 %, and the green relative density is 58.5 % with a homogeneous microstructure. After sintering at 1300 °C, the ceramic core exhibits a uniform microstructure with a bending strength of 25 ± 1.2 MPa, a sintered shrinkage of 11.31 %, a relative density of 92.3 %, and an apparent porosity of 30.5 %. The solubility rate of the ceramic core is 2.83 kg/min m2, and the dissolution of the ceramic core in water is exothermal. The water-soluble calcia-based ceramic core fabricated by aqueous gel casting using epoxy resin could overcome the poor leachability of the common ceramic core and enhanced the production efficiency.

Similar content being viewed by others

References

Wereszczak AA, Breder K, Ferber MK, Kirkland TP, Payzant EA, Rawn CJ, Krug E, Larocco CL, Pietras RA, Karakus M (2002) Dimensional changes and creep of silica core ceramics used in investment casting of superalloys. J Mater Sci 37(19):4235–4245

Lu ZL, Fan YX, Miao K, Jing H, Li DC (2014) Effects of adding aluminum oxide or zirconium oxide fibers on ceramic molds for casting hollow turbine blades. Int J Adv Manuf Technol 72(5–8):873–880

Wu H, Li D, Chen X, Sun B, Xu D (2010) Rapid casting of turbine blades with abnormal film cooling holes using integral ceramic casting molds. Int J Adv Manuf Technol 50(1–4):13–19

Ding WJ, Fu PH, Peng LM (2011) Advanced magnesium alloys and their applications in aerospace. Spacecr Environ Eng 28:103–109

Shah D N, Beals J T, Marcin Jr J J (2003) Cores for use in precision investment casting: U.S. Patent 6637500

Wang F, Li F, He B (2013) Gel-casting of fused silica based core packing for investment casting using silica sol as a binder. J Eur Ceram Soc 33:2745–2749

Lee Y W (2000) Water soluble ceramic core for use in die casting, gravity and investment casting of aluminum alloys. U.S. Patent 6024787

Mills D (1986) Dissolving ceramic materials. U.S. Patent 4569384

Jiang WG, Dong JS, Lou LH (2010) Preparation and properties of a novel water soluble core material. J Mater Sci Technol 26:270–275

Li H, Chen J, Chandrashekhara K, Xu M, Lekakh SN, Richards VL (2015) Characterization and modeling of anisotropic SL pattern during investment casting process. Int J Adv Manuf Technol 80(9–12):1933–1943

Bhattacharya TK, Ghosh A, Das SK (2001) Densification of reactive lime from limestone. Ceram Int 27:455–459

Kurama S, Ozel E (2009) The influence of different CaO source in the production of anorthite ceramics. Ceram Int 35:827–830

Janney M A, Omatete O O (1991) Method for molding ceramic powders using a water-based gel casting: U.S. Patent 5028362

Omatete OO, Janney MA, Nunn SD (1997) Gelcasting: from laboratory development toward industrial production. J Eur Ceram Soc 17:407–413

Young AC, Omatete OO, Janney MA (1991) Gelcasting of alumina. J Am Ceram Soc 74:612–618

Yang J, Yu J, Huang Y (2011) Recent developments in gelcasting of ceramics. J Eur Ceram Soc 31:2569–2591

Kokabi M, Babaluo AA, Barati A (2006) Gelation process in low-gelcasting systems. J Eur Ceram Soc 26:3083–90

Dong MJ, Mao XJ, Zhang ZQ (2009) Gelcasting of SiC using epoxy resin as gel former. Ceram Int 35:1363–1366

Mao XJ, Shimai SZ, Dong MJ (2007) Gelcasting of alumina using epoxy resin as a gelling agent. J Am Ceram Soc 90:986–988

Tulliani J, Lombardi M, Palmero P (2013) Development and mechanical characterization of novel ceramic foams fabricated by gel-casting. J Eur Ceram Soc 33:1567–1576

Zhao HP, Ye CS, Fan ZT (2014) A simple and effective method for gel casting of zirconia green bodies using phenolic resin as a binder. J Eur Ceram Soc 34(5):1457–1463

Barners HA, Hutton JF, Walters K (1992) An introduction to rheology. China petrifaction press, China

Onbattuvelli V (2011) The effects of nanoparticle addition on the processing, structure and properties of SiC and AlN. Oregon State University

Onbattuvelli VP, Enneti RK, Park SJ, Atre S (2013) The effects of nanoparticle addition on SiC and AlN powder–polymer mixtures: packing and flow behavior. Int J Refract Met Hard Mater 36:183–190

Wang XF, Wang RC, Peng CQ, Luo YL, Wang ZY (2012) Gelation kinetics and uniformity of gelcasting. J Cent South Univ 43(4):1281–1289

Zhang YL, Zhang YM, Zhao XJ, Han JC (2007) Research development of ceramics slurry in the wet forming process. Ordnance Mater Sci Eng 30(1):66–71

Hu YC, Wang ZJ, Lu JY (2008) Study on the gel casting of fused silica glass. J Non-Cryst Solids 354(12):1285–1289

Shao XJ, Dong PA, Wei YH (2003) Inorganic chemistry. Wuhan university press, China

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, F., Fan, Z., Liu, X. et al. Aqueous gel casting of water-soluble calcia-based ceramic core for investment casting using epoxy resin as a binder. Int J Adv Manuf Technol 86, 1235–1242 (2016). https://doi.org/10.1007/s00170-015-8227-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8227-3