Abstract

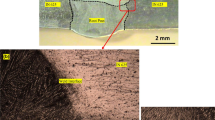

Flux-cored arc welding (FCAW) is one of the popularly used welding processes in the fabrication of carbon steels and low alloy steel. It is a semi-automatic or automatic arc welding process. Boiler quality (BQ) steels or pressure vessel plates are superior quality carbon steels which have consistent controlled properties and are designed to withstand the internal pressure of pressure vessels, boilers, and valves. To explore the potential advantages in joining BQ steels by FCAW, the present study focuses on microstructure and microhardness characterization of weldment. Microscopic examinations have been performed using optical microscopy of the welded specimens, to evaluate the microstructures of the weld metal, heat-affected zone (HAZ), and base metal. The microhardness test has also been performed using the Vickers scale. A qualitative comparison of the microstructural features and microhardness values at three different heat input levels—high, low, and medium—are made in the present work.

Similar content being viewed by others

References

Lia MT, Chen WJ (1999) A comparison of gas metal arc welding with flux-cored wires and solid wires using shielding gas. Int J Adv Manuf Technol 15:49–53, Springer-Verlag London Limited

Clemex intelligent microscopy, Application note (2009) Micro-hardness testing of heat affected zones, www.clemex.com I 1.888.651.6573, Printed in Canada 09/01

Jiang IANG Q, Li Y, Wang J, Zhang L (2011) Characterization on strength and toughness of welded joint for Q550 steel. Bull Mater Sci 34(1):161–167, Indian Academy of Sciences

Baltazar Hernandez VH, Kuntz ML, Khan MI, Zhou Y (2008) Influence of microstructure and weld size on the mechanical behaviour of dissimilar AHSS resistance spot welds. Sci Technol Weld Join 13(8):769

Babu SS, David SA, Vitek JM (1995) Phase transformations and microstructure develoDment in low allov steel welds. Submitted to the International Symposium on Phase Transformations during the Thermal/Mechanical Processing of Steel. Vancouver, Canada, 20–23

Kumar V (2011) Metallographic investigations, Chapter 6

Hardness Testing of Welds TGN-PE-01, Welding Technology Institute of Australia, March 2006

Bhadeshia HKDH, Svensson LE (1993) Modelling the evolution of microstructure in steel weld metal. Mathematical Modelling of Weld Phenomena, Institute of Materials, London, pp 109–182

Ozekcin A, Jin HW, Koo JY, Bangaru NV, Ayer R (2004) A microstructural study of friction stir welded joints of carbon steels. Int J Offshore Polar Eng 14(4):284–288, ISSN 1053–5381

Lianghong XU, Zhang Jun C, Yanqing N (2011) Effect of heat input on the microstructure and mechanical properties of 07MnCrMoVR weld joints. Chin J Mech Eng 24:1–7

Prasad K, Dwivedi DK (2008) Some investigations on microstructure and mechanical properties of submerged arc welded HSLA steel joints. Int J Adv Manuf Technol 36:475–483

Sakthivel T, Senga GS, Mukhopadhyay J (2009) Effect of welding speed on microstructure and mechanical properties of friction-stir-welded aluminum. Int J Adv Manuf Technol 43:468–473

Gen S, Yao YL, Qiu C (2013) Strength and microstructure of laser fusion-welded Ti–SS. Int J Adv Manuf Technol 66:469–479

Jaiswal D (2013) Analysing the effect of parameters in multipass submerged arc welding process. Int J Theor Appl Res Mech Eng 2(2):60–70

Popović O, Prokić-Cvetković R, Burzić M, Milutinović Z (2010) The effect of Heatinput on the Weld Metal Toughness of Surface Welded Joint, 14th International Research/Expert Conference. Trends in the Development of Machinery and Associated Technology”, pp. 61 – 64

Tabuchi M, Hongo H, Abe F (2013) Creep strength of dissimilar welds for advanced USC boiler materials, 13th International Conference on Fracture, Beijing, China, pp. 1–7

Tabuchi M, Hongo H (2011) Evaluation of microstructure and creep damage in high-Cr ferritic steel welds. Acta Metall Sin (Engl Lett) 24(3):225–234

Joarder A., Saha, SC, Ghose AK (1991) Study of submerged arc weld metal and heat-affected zone microstructures of a plain carbon steel, Weld Res Suppl, 141 – 148

Murat Tolga Erturk (2011) Microstructural and mechanical characterization of metal active gas welded joint between cast iron and low carbon steel, a thesis submitted to the graduate school of natural and applied sciences of middle east technical university, 1 – 82

Tapany Udomplal (2007) Solidification and phase transformations in welding, Suranaree University of Technology, 1–36

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Biswas, B.K., Bandyopadhyay, A. & Pal, P.K. Microstructure and microhardness of flux-cored arc-welded joints for boiler quality steel. Int J Adv Manuf Technol 80, 2061–2072 (2015). https://doi.org/10.1007/s00170-015-7159-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7159-2