Abstract

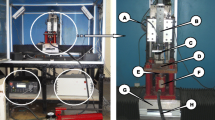

An experimental investigation on laser transmission welding of polycarbonate is presented in this paper. Instead of concentrating on the well-known effects of process parameters, the present study focuses on the sensitivity analysis of process parameters to identify the critical parameters and to assess their relative impact on the variation in output quality. Curvilinear regression models are developed using the independently controllable design variables like laser power (W), welding speed (mm/s), standoff distance (mm), and clamp pressure (MPa). Selected weld quality characteristics, namely the weld strength (N/mm), which is calculated based on failure load per unit length and weld width (mm), are used to set the objective functions. Parametric sensitivity analyses are performed using the developed models. It is observed from the results of sensitivity analysis that the weld strength is more sensitive to welding speed (sensitivity of 8.4 N/mm per unit welding speed) and laser power (sensitivity of 3.08 N/mm per unit laser power), whereas weld width is more sensitive to welding speed (sensitivity of 0.37 mm per unit welding speed) and standoff distance (sensitivity of 0.11 mm per unit standoff distance), respectively. These are the critical parameters for the respective quality characteristics, and a small variation of these parameters causes relatively higher deviation in weld quality.

Similar content being viewed by others

References

Acherjee B, Kuar AS, Mitra S, Misra D (2010) Selection of process parameters for optimizing the weld strength in laser transmission welding of acrylics. Proc Inst Mech Eng B J Eng Manuf 224(10):1529–1536

Abed S, Laurens P, Carrétéro C, Deschamps JR, Duval C, (2001) Diode laser welding of polymers: microstructures of the welded zones for polypropylene. Proceedings of the 20th International Congress on Applications of Lasers & Electro-Optics, Jacksonville, Florida, USA, October 15–18

Baylis B (2002) Welding thermoplastic elastomers to polypropylene with a diode laser. Proceedings of the 21st International Congress on Applications of Lasers & Electro-Optics, Scottsdale, Arizona, USA, October 14–17

Douglass DM, Wu CY, (2003) Laser welding of polyolefin elastomers to thermoplastic polyolefin. Proceedings of the 22nd International Congress on Applications of Lasers & Electro-Optics, Jacksonville, Florida, USA, October 13–16

Jansson A, Kouvo S, Salminen A, Kujanpää V (2003) The effect of parameters on laser transmission welding of polymers. Proceedings of the 22nd International Congress on Applications of Lasers & Electro-Optics, Jacksonville, Florida, USA, October 13–16

Grewell D, Rooney P, Kagan VA (2004) Relationship between optical properties and optimized processing parameters for through-transmission laser welding of thermoplastics. J Reinf Plast Compos 23(3):239–247

Prabhakaran R, Kontopoulou M, Zak G, Bates PJ, Baylis BK (2006) Contour laser—laser-transmission welding of glass reinforced nylon 6. J Thermoplast Compos Mater 19:427–439

Haberstroh E, Hoffmann WM, Poprawe R, Sari F (2006) 3 laser transmission joining in microtechnology. Microsyst Technol 12:632–639

Wehner M, Jacobs P, Poprawe R (2007) Rapid prototyping of micro-fluidic components by laser beam processing. Proc SPIE 6459:6459081–12

Ghorbel E, Casalino G, Abed A (2008) Laser diode transmission welding of polypropylene: geometrical and microstructure characterization of weld. Mater Des 30:2745–2751

Kawahito Y, Niwa Y, Katayama S (2009) Laser direct joining of ceramic and engineering plastic. Proceedings of the 28th International Congress on Applications of Lasers and Electro-Optics, Orlando, FL, USA, November 2–5

Amanat N, Chaminade C, Grace J, McKenzie DR, James NL (2010) Transmission laser welding of amorphous and semi-crystalline poly-ether–ether–ketone for applications in the medical device industry. Mater Des 31:4823–4830

Acherjee B, Misra D, Bose D, Venkadeshwaran K (2009) Prediction of the weld strength and seam width for laser transmission welding of thermoplastics using response surface methodology. Opt Laser Technol 41:956–967

Acherjee B, Kuar AS, Mitra S, Misra D (2011) Application of grey-based Taguchi method for simultaneous optimization of multiple quality characteristics in laser transmission welding process of thermoplastics. Int J Adv Manuf Technol 56(9–12):995–1006

Acherjee B, Mondal S, Tudu B, Misra D (2011) Application of artificial neural network for predicting weld quality in laser transmission welding of thermoplastics. Appl Soft Comput 11:2548–2555

Acherjee B, Kuar AS, Mitra S, Misra D (2010) Finite element simulation of laser transmission welding of dissimilar materials between polyvinylidene fluoride and titanium, International Journal of Engineering. Sci Technol 2(4):176–186

Acherjee B, Kuar AS, Mitra S, Misra D (2013) Finite element simulation of laser transmission thermoplastic welding of circular contour using a moving heat source. Int J Mechatron Manuf Syst 6(5/6):437–454

Gunaraj V, Murugan N (2000) Prediction and optimization of weld bead volume for the submerged arc process, part 2. Weld J 79(11):331s–338s

Kim IS, Son KJ, Yang YS, Yaragada PKDV (2003) Sensitivity analysis for process parameters in GMA welding processes using a factorial design method. Int J Mach Tools Manuf 43:763–769

Karaoglu S, Secgin A (2008) Sensitivity analysis of submerged arc welding process parameters. J Mater Process Technol 202:500–507

Acherjee B, Kuar AS, Mitra S, Misra D (2012) Experimental study on laser transmission welding of polycarbonate using Box-Behnken statistical design, Proc. 4th Int & 25th AIMTDR conf., Jadavpur University, 216–221

Acherjee B (2011) Numerical and experimental investigation of laser transmission welding of thermoplastics, PhD Thesis, Jadavpur University, Kolkata, India

Lakshminarayanan AK, Balasubramanian V (2009) Comparison of RSM with ANN in predicting tensile strength of friction stir welded AA7039 aluminium alloy joints. Trans Nonferrous Metals Soc China 19:9–18

Acherjee B, Kuar AS, Mitra S, Misra D (2012) Modeling and analysis of simultaneous laser transmission welding of polycarbonates using an FEM and RSM combined approach. Opt Laser Technol 44(4):995–1006

Acherjee B, Kuar AS, Mitra S, Misra D (2012) Modeling of laser transmission contour welding process using FEA and DoE. Opt Laser Technol 44(5):1281–1289

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Acherjee, B., Kuar, A.S., Mitra, S. et al. Laser transmission welding of polycarbonates: experiments, modeling, and sensitivity analysis. Int J Adv Manuf Technol 78, 853–861 (2015). https://doi.org/10.1007/s00170-014-6693-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6693-7