Abstract

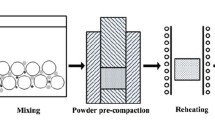

This paper studied the combined effects of matrix-to-reinforcement particle size ratio (PSR) and SiC volume fraction on the mechanical properties of extruded Al–SiC composites. A powder metallurgy technique (PM) of cold pressing at 500 MPa followed by hot extrusion at 580 °C was adopted to produce Al/SiC composite. Aluminum powder of size 60 μm and silicon carbide with different sizes, i.e., 50, 20, and 8 μm, were used. Three different volume fractions of SiC were employed, i.e., 5, 10, and 15 %, for each investigated size using a constant extrusion ratio of 14.36. The effect of matrix-to-reinforcement PSR on the reinforcement spatial distribution, fabricability, and resulting mechanical properties of a PM-processed Al/SiC composite were investigated. It has been shown that small ratio between matrix to reinforcement particle size resulted in more uniform distribution of the SiC particles in the matrix. As the PSR increases, the agglomerations and voids increase and the reinforcement particulates seem to have nonuniform distribution. In addition, the agglomerations increased as the volume fraction of the SiC increased. It has also been shown that homogenous distribution of the SiC particles resulted in higher yield strength, ultimate tensile strength, and elongation. Yield strength and ultimate tensile strength of the composite reinforced by PSR (1.2) are higher than those of composite reinforced by PSR (7.5), while the elongation shows opposite trend with yield strength and ultimate tensile strength.

Similar content being viewed by others

References

Clyne TW, Withers PJ (1993) An introduction to metal matrix composites. Cambridge University Press, Cambridge

Torralba JM, da Costa CE, Velasco F (2003) P/M aluminum matrix composites: an overview. J Mater Process Technol 133:203–206

Maruyama B, Hunt WH Jr (1999) Discontinuously reinforced aluminum: status and future direction. J Met 51:59–61

Chawla N, Shen YL (2001) Mechanical behavior of particle reinforced metal matrix composites. Adv Eng Mater 3:357–370

Hong SJ, Kim HM, Huh D, Suryanarayana C, Chun BS (2003) Effect of clustering on the mechanical properties of SiC particulate-reinforced aluminum alloy 2024 metal matrix composites. Mater Sci Eng A 347:198–204

Narayanasamy R, Ramesh T, Prabhakar M (2009) Effect of particle size of SiC in aluminum matrix on workability and strain hardening behavior of P/M composite. Mater Sci Eng A 504:13–23

Davis LC, Allison JE (1993) Residual stresses and their effects on deformation in particle-reinforced metal-matrix composites, Metall. Trans A 24:2487–2496

Krajewski PE, Allison JE, Jones JW (1993) The influence of matrix microstructure and particle reinforcement on the creep behavior of 2219 aluminum. Metall Mater Trans A 24:2731–2741

Chawla N, Andres C, Jones JW, Allison JE (1998) Effect of SiC volume fraction and particle size on the fatigue resistance of a 2080 Al/SiC p composite. Metall Mater Trans A 29:2843–2854

Rack HJ (1987) Light-weight, high-performance metal matrix composites, processing and properties for powder metallurgy composites. Proceeding of a symposium sponsored by the P/M committee of TMS/AIME held at the annual meeting of metallurgical society in Denver, Colorado, p 155

Slipenyuk A, Kuprin V, Milman Y, Goncharuk V, Eckert J (2006) Properties of P/M processed particle reinforced metal matrix composites specified by reinforcement concentration and matrix-to-reinforcement particle size ratio. Acta Mater 54:157–166

Lewandowski JJ, Liu C, Hunt WH, Kumar P, Vedula K (Eds) Powder metallurgy composites, TMS, Warrendale, PA, (1988) 117.

Stone IC, Welson CE, Tsakiropoulos P (1997) The dependence of aging on 3-dimensional spatial distribution of reinforcement in Al-4wt% Cu/SiCP MMCs. Scr Mater 37:305–310

Sternowsky SB, Donnel GO, Looney B (1997) Key engineering materials, Trans Tech Publications, Switzerland, 127 455.

Kok M (2005) Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminum alloy composites. J Mater Process Technol 161:381–38

Stone IC, Tsaikiropoulos P, Miravete A (Ed) (1993) Metal matrix composites, ICCM/9, Vol. 1, WoodHead Publishing Ltd., 271–278.

Stone IC, Tsakiropoulos P (1998) The effect of reinforcement on the notched and unnotched room temperature tensile properties of Al-4wt% Cu/SiCp MMCs. Mater Sci Eng A 241:19–29

Lin YC, Li HC, Liou SS, Shie MT (2004) Mechanism of plastic deformation of powder metallurgy metal matrix composites of Cu–Sn/SiC and 6061/SiC under compressive stress. Mater Sci Eng A 373:363–369

Nlü BS (2008) Investigation of tribological and mechanical properties Al2O3–SiC reinforced Al composites manufactured by casting or P/M method. Mater Des 29:2002–2008

Kok M (2006) Abrasive wear of Al2O3 particle reinforced 2024 aluminium alloy composites fabricated by vortex method. Compos Part A 37:457–464

Deng KK, Wang XJ, Wu YW, Hu XS, Wu K, Gan WM (2012) Effect of particle size on microstructure and mechanical properties of SiCp/AZ91 magnesium matrix composite. Mater Sci Eng A 543:158–163

Williams JJ, Piotrowski G, Saha R, Chawla N (2002) Effect of overaging and particle size on tensile deformation and fracture of particle-reinforced aluminum matrix composites. Metall Mater Trans A 33:3861–3869

Corbin SF, Wilkinson DS (1994) Low strain plasticity in a particulate metal matrix composite. Acta Metall Mater 42:1319–1327

Liu ZY, Wang QZ, Xiao BL, Ma ZY, Liu Y (2010) Experimental and modeling investigation on SiCp distribution in powder metallurgy processed SiCp/2024 Al composites. Mater Sci Eng A 527:5582–5591

Chawla N, Andres C, Jones JW, Allison JE (1998) Cyclic stress-strain behavior of particle reinforced metal matrix composites. Scripta Mater 38:1596–1600

Finot M, Shen YL, Needleman A, Suresh S (1994) Micromechanical modeling of reinforcement fracture in particle-reinforced metal-matrix composites. Metall Mater Trans A 25:2403–2420

Wang Z, Song M, Sun C, He Y (2011) Effects of particle size and distribution on the mechanical properties of SiC reinforced Al–Cu alloy composites. Mater Sci Eng A 528:1131–1137

Slipenyuk A, Kuprin V, Milman Y, Spowart JE, Miracle DB (2004) The effect of matrix to reinforcement particle size ratio (PSR) on the microstructure and mechanical properties of a P/M processed AlCuMn/SiCp MMC. Mater Sci Eng A 381:165–170

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fathy, A., Sadoun, A. & Abdelhameed, M. Effect of matrix/reinforcement particle size ratio (PSR) on the mechanical properties of extruded Al–SiC composites. Int J Adv Manuf Technol 73, 1049–1056 (2014). https://doi.org/10.1007/s00170-014-5901-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5901-9