Abstract

A model to predict residual stresses produced from milling is presented. It uses process conditions as inputs and predicts surface and subsurface residual stress profiles due to milling. The model formulation incorporates cutting force and cutting temperature predictions and utilizes those parameters to define the thermomechanical loading experienced by the workpiece. Model predictions are compared with published experimental data for both cutting forces and residual stress profiles. The results show that the model performs well in predicting residual stress trends for various milling conditions. Residual stress magnitudes as well as profiles are well predicted with the modeling approach.

Similar content being viewed by others

References

Henriksen EK (1951) Residual stresses in machined surfaces. Am Soc Mech Eng Trans 73(1):69–76

Liu CR, Barash MM (1982) Variables governing patterns of mechanical residual stress in a machined surface. J Eng Ind Trans ASME 104(3):257–264

Jang DY et al (1996) Surface residual stresses in machined austenitic stainless steel. Wear 194(1–2):168–173

Matsumoto Y, Hashimoto F, Lahoti G (1999) Surface integrity generated by precision hard turning. CIRP Ann Manuf Technol 48(1):59–62

Fuh K-H, Wu C-F (1995) Residual-stress model for the milling of aluminum alloy (2014-T6). J Mater Process Technol 51(1–4):87–105

Jacobus JK, Kapoor SG, DeVor RE (2001) Experimentation on the residual stresses generated by endmilling. J Manuf Sci Eng 123:748–756

Mantle AL, Aspinwall DK (2001) Surface integrity of a high speed milled gamma titanium aluminide. Elsevier Science Ltd., Amsterdam

Li HZ, Zhang WB, Li XP (2001) Modelling of cutting forces in helical end milling using a predictive machining theory. Int J Mech Sci 43(8):1711–1730

Young HT, Mathew P, Oxley PLB (1987) Allowing for nose radius effects in predicting the chip flow direction and cutting forces in bar turning. Proc Inst Mech Eng C Mech Eng Sci 201(3):213–226

Young H-T et al (1993) Predicting the chip flow for nose radius tools under oblique machining conditions. J Chin Inst Eng Trans Chin Inst Eng Ser A/Chung-kuo Kung Ch’eng Hsuch K’an 16(6):825–834

Arsecularatne JA, Mathew P, Oxley PLB (1995) Prediction of chip flow direction and cutting forces in oblique machining with nose radius tools. Proc Inst Mech Eng B J Eng Manuf 209(B4):305–315

Stabler GV (1951) Fundamental geometry of cutting tools. Inst Mech Eng Proc 165(63):14–21

Altintas Y (2000) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design, vol xii. Cambridge University Press, New York, p 286

Oxley PLB (1989) The mechanics of machining: an analytical approach to assessing machinability (Ellis Horwood series in mechanical engineering). Halsted, New York, p 242

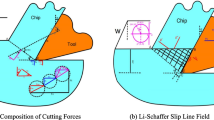

Waldorf DJ, DeVor RE, Kapoor SG (1998) Slip-line field for ploughing during orthogonal cutting. J Manuf Sci Eng Trans ASME 120(4):693–698

Lin Z-C, Lin Y-Y, Liu CR (1991) Effect of thermal load and mechanical load on the residual stress of a machined workpiece. Int J Mech Sci 33(4):263–278

Jaeger JC (1942) Moving sources of heat and temperature at sliding contacts. R Soc NSW J Proc 76(Part 3):203–224

Komanduri R, Hou ZB (2000) Thermal modeling of the metal cutting process part I—temperature rise distribution due to shear plane heat source. Int J Mech Sci 42(9):1715–1752

Komanduri R, Hou ZB (2001) Analysis of heat partition and temperature distribution in sliding systems. Wear 251(1–12):925–938

Trigger KJ, Chao BT (1951) Analytical evaluation of metal-cutting temperatures. Am Soc Mech Eng Trans 73(1):57–60

Sekhon GS, Chenot JL (1993) Numerical simulation of continuous chip formation during non-steady orthogonal cutting. Eng Comput (Swansea, Wales) 10(1):31–48

Komanduri R, Hou ZB (2001) Thermal modeling of the metal cutting process—part Ii: temperature rise distribution due to frictional heat source at the tool-chip interface. Int J Mech Sci 43(1):57–88

Wu DW, Matsumoto Y (1990) Effect of hardness on residual stresses in orthogonal machining of AISI 4340 steel. J Eng Ind Trans ASME 112(3):245–252

McDowell DL (1997) Approximate algorithm for elastic–plastic two-dimensional rolling/sliding contact. Wear 211(2):237–246

McDowell DL, Moyar GJ (1986) A more realistic model of nonlinear material response: application to elastic–plastic rolling contact. In Proceedings of the 2nd International Symposium on Contact Mechancis and Wear of Rail/Wheel Systems. Kingston, RI

Jiang Y, Sehitoglu H (1994) Analytical approach to elastic–plastic stress analysis of rolling contact. J Tribol Trans ASME 116(3):577–587

Merwin JE, Johnson KL (1963) An analysis of plastic deformation in rolling contact. Proceedings, Institution of Mechanical Engineers, London 177(25):676–685

Metals Affordability Initiative (MAI) Machining Distortion (2006)

Huang Y (2002) Predictive modeling of tool wear rate with application to CBN hard turning. Ph.D. thesis, Georgia Institute of Technology, Atlanta, GA

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Su, JC., Young, K.A., Ma, K. et al. Modeling of residual stresses in milling. Int J Adv Manuf Technol 65, 717–733 (2013). https://doi.org/10.1007/s00170-012-4211-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4211-3