Abstract

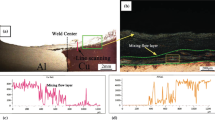

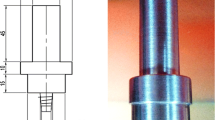

In this work, the thermomechanical responses during the dissimilar friction stir welding of aluminum alloys have been evaluated employing a three-dimensional model and the finite element software ABAQUS. Furthermore, welding experiments have been conducted under different working conditions and the temperature variations during and after welding as well as the produced residual stresses in various positions of the welded samples were measured using hole-drilling technique. The model results were then examined by experimental data, and a reasonable agreement was observed. It is found that tool rotational speed significantly affects the amount of maximum tensile residual stress while traverse speed mainly changes the distribution of transverse residual stresses. Also, both experimental and simulated results indicate that welding fixtures significantly affect the residual stress profiles as well as their magnitudes.

Similar content being viewed by others

References

Steuwer A, Peel MJ, Withers PJ (2006) Dissimilar friction stir welds in AA5083–AA6082: the effect of process parameters on residual stress. Mater Sci Eng A 441:187–196

Fratini L, Zuccarello B (2006) An analysis of through-thickness residual stresses in aluminium FSW butt joints. Int J Mach Tool Manuf 46:611–619

Linton VM, Ripley MI (2008) Influence of time on residual stresses in friction stir welds in agehardenable 7xxx aluminium alloys. Acta Mater 56:4319–4327

Peel M, Steuwer A, Preuss M, Withers PJ (2003) Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds. Acta Mater 51:4791–4801

Staron P, Kocaka M, Williams S, Wescott A (2004) Residual stress in friction stir-welded Al sheets. Physica B 350:e491–e493

Dubourg L, Doran P, Larose S, Gharghouri MA, Jahazi M (2010) Prediction and measurements of thermal stresses in AA2024-T3 friction stir welds as a function of welding parameters. Mater Sci Forum 638–642:1215–1220

Yujie S, Yong Z, Qing-yu S (2010) Numerical simulations of friction stir welding process and subsequent post weld cold rolling process. Key Eng Mater 419–420:433–436

Prime MB, Herold TG, Baumann JA, Lederich RJ, Bowden DM, Sebring RJ (2006) Residual stress measurements in a thick, dissimilar aluminum alloy friction stir weld. Acta Mater 54:4013–4021

Khandkar MH, Khan JA, Reynolds AP, Sutton MA (2006) Predicting residual thermal stresses in friction stir welded metals. J Mater Process Technol 174:195–203

Rajesh SR, Bang HS, Chang WS, Kim HJ, Bang HS, Oh CI, Chu JS (2007) Numerical determination of residual stress in friction stir weld using 3D-analytical model of stir zone. J Mater Process Technol 187–188:224–226

Bastier A, Maitournam MH, Roger F, Van Dang K (2008) Review: modelling of the residual state of friction stir welded plates. J Mater Process Technol 200:25–37

Hibbit D, Karlsson B, Sorenson P (2004) Abaqus/explicit user’s manual, version 6.5, Abaqus Inc.

Prasad YVRK, Sasidhara S (eds) (1997) Hot working guide: a compendium of processing maps. ASM International, Materials Park, pp 101–106

Chao Y, Qi X (1998) Thermal and thermo-mechanical modeling of friction stir welding of aluminum alloy 6061-T6. J Mater Process Manuf Sci 7:215–233

Kim D, Badarinarayan H, Kim JH, Kim C, Okamoto K, Wagoner RH, Chung K (2010) Numerical simulation of friction stir butt welding process for AA5083-H18 sheets. Eur J Mech A Solids 29:204–215

Dunne F, Petrinic N (2005) Introduction to computational plasticity. Oxford University Press, Oxford, pp 89–90

Schmidt H, Hattel J (2005) A local model for the thermo-mechanical conditions in friction stir welding. Model Simul Mater Sci Eng 15:77–93

Jamshidi Aval H, Serajzadeh S, Kokabi AH (2011) Thermo-mechanical and microstructural issues in dissimilar friction stir welding of AA5086-AA6061. J Mater Sci 46:3258–3268

ASTM Standard E837-99 (2001) Standard test method for determining residual stresses by the hole-drilling strain-gage method. American Society for Testing and Materials, Philadelphia, pp 675–684

Awang M (2007) Simulation of friction stir spot welding (FSSW) process: study of friction phenomena. PhD Thesis, West Virginia University, West Virginia

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jamshidi Aval, H., Serajzadeh, S. & Kokabi, A.H. Experimental and theoretical evaluations of thermal histories and residual stresses in dissimilar friction stir welding of AA5086-AA6061. Int J Adv Manuf Technol 61, 149–160 (2012). https://doi.org/10.1007/s00170-011-3713-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3713-8