Abstract

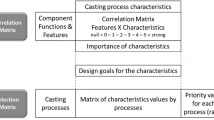

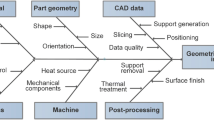

Design for manufacture usually implies applying various guidelines derived from previous experience to improve part design so it is more compatible with the capabilities of the selected process, resulting in better quality and lower cost. The guidelines can be formulated as dimensionless criteria, enabling quantitative evaluation of a particular aspect of part design. There is, however, no good way to compare two or more designs for all aspects, considering that they may not be equally important. In this work, we employ analytical hierarchy process to determine the relative weights of various criteria for castability evaluation. The criteria are categorised in a three-level hierarchy, with the middle level comprising mould, feeding and gating groups. The prioritisation of criteria along with consistency checking of pair-wise comparisons enables a systematic evaluation of alternative product designs for manufacturability. The methodology is illustrated by modifying the product and tooling design of a grey iron bracket casting and estimating the improvement in manufacturability. The results are supported by experiments.

Similar content being viewed by others

References

Andreasen MM, Hein L (1997) Integrated product development. IFS, UK

Magrab E (1997) Integrated product and process design and development. CRC, New York

ASM (1962) Casting design handbook. American Society of Metals, Ohio

Steel Founders’ Society of America (1973) Risering steel castings. http://www.sfsa.org/

ASM (1990) Metal handbook volume 15 casting. American Society of Metals, Ohio

Bralla J (1990) Handbook of product design for manufacturing. McGraw-Hill Book, New York

Campbell J (2004) Castings practice the 10 rules of casting. Elsevier, Oxford

Ravi B (2005) Metal casting—computer aided design and analysis. Prentice Hall, India

Gupta SK, Regli WC, Das D, Nau DS (1997) Automated manufacturability analysis: a survey. Res Eng Design—Theory Appl Concurrent Eng 9(3):p168–p190

Ravi B, Srinivasan MN (1995) Features-based castability evaluation. Int J Prod Res 33(12):p3367–p3380

Saaty T (1994) Highlights and critical points in the theory and application of the analytic hierarchy process. Eur J Oper Res 74(3):426–447

Saaty T (1994) How to make decision: the analytic hierarchy process. Interfaces 24(6):19–43

Akarte M, Surendra N, Ravi B, Rangraj N (2001) Web-based casting supplier evaluation using analytic hierarchy process. J Oper Res Soc 52:p511–p522

Tiwari M, Banerjee R (2001) A decision support system for the selection of a casting process using analytic hierarchy process. Prod Plan Control 12(7):p689–p694

Chougule RG, Ravi B (2005) Variant process planning of casting using AHP-based nearest neighbor algorithm for case retrieval. Int J Prod Res 43(6):1255–1273

Ravi B, Srinivasan MN (1996) Casting solidification analysis by modulus vector method. Int J Cast Met Res 9:1–7

Ravi B, Creese RC, Ramesh D (1999) Design for casting—a new paradigm for preventing potential problems. Trans Am Foundry Soc 107:p197–p202

Ravi B, Joshi D (2007) Feedability analysis and optimization driven by casting simulation. Indian Foundry J 53(6):71–78

Ravi B, Joshi D, Kamalesh S. (2008) Part, tooling and method optimization driven by simulation and cost model. 68th World Foundry Congress, Chennai, Feb 7–10, pp 261–266

Joshi D, Ravi B (2008) Comparison of finite element method and vector element method for casting solidification simulation. Indian Foundry J 54(9):21–27

Joshi D, Ravi B (2009) Classification and simulation based design of 3D junctions in castings. Trans Am Foundry Soc 117:p7–p22

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Joshi, D., Ravi, B. Early castability evaluation using analytical hierarchy process. Int J Adv Manuf Technol 50, 21–36 (2010). https://doi.org/10.1007/s00170-010-2517-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2517-6