Abstract

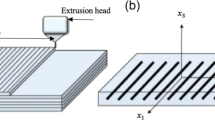

A statistical design of experiments (DOE) approach was used to determine if specific build orientation parameters impacted mechanical strength of stereolithography (SL) fabricated parts. A single platform (25.4 × 25.4-cm cross-section) on the 3D Systems Viper si2 SL machine was designed to hold 18 ASTM D-638 type I samples manufactured in different orientations. The DOE tested three factors: axis, layout, and position. Samples were fabricated parallel with the x-axis or y-axis, or 45° to both axes (called axes 1, 2, and 3, respectively). For each axis, samples were fabricated either flat or on an edge relative to the x–y plane (called layouts 1 and 2, respectively). Three samples were manufactured for each layout and axis combination, and the samples were labeled as positions 1, 2, or 3 depending on the distance from the center of the platform with position 1 being the closest to the center. The results from the statistical analyses showed that axis and position had no significant effect on ultimate tensile stress (UTS) or modulus of elasticity in tension (E). However, layout (or whether a sample was built flat or on an edge) was shown to have a statistically significant effect on UTS and E (at a 95% level of confidence). The differences between average UTS and E for each of the samples built flat and on an edge were ~3.53% (43.2 versus 44.8 MPa) and ~4.59% (763.9 versus 800.7 MPa), respectively. Because of the relatively small differences in means for UTS and E, the statistical differences between layout most likely would not have been identified without performing the multifactor analysis of variance. Furthermore, layout was the only factor that tested different orientations of build layers (or layer-to-layer interfaces) with respect to the sample part, and thus, it appears that the orientation of the build layer (layer-to-layer interfaces) with respect to the fabricated part has a significant effect on the resulting mechanical properties. This study represents one of many to follow that is using statistical analyses to identify and classify important fabrication parameters on mechanical properties for layer-manufactured parts. Although SL is the focus of this work, the techniques developed and presented here can be applied to any layered manufacturing technology producing any ASTM-type specimen with any particular material.

Similar content being viewed by others

References

Byun HS, Lee KH (2005) A decision support system for the selection of a rapid prototyping process using the modified TOPSIS method. Int J Adv Manuf Technol 26(11–12):1338–1347. doi:10.1007/s00170-004-2099-2

Giannatsis J, Dedoussis V (2007) Decision support tool for selecting fabrication parameters in stereolithography. Int J Adv Manuf Technol 33(7–8):706–718. doi:10.1007/s00170-006-0496-4

Jacobs PF (1992) RP & M technologies: fundamentals of stereolithography. SME, Dearborn, MI

Jacobs PF (1996) Stereolithography and other RP & M technologies: from rapid prototyping to rapid tooling. ASME, New York, NY

Wohlers T (2004) Wohlers report 2004: rapid prototyping, tooling and manufacturing, state of the industry. Wohlers Associates, Annual Worldwide Progress Report

Palmer JA, Yang P, Davis DW, Chavez BD, Gallegos PL, Wicker RB, Medina F (2004) Rapid prototyping of high density circuitry. SME Technical Paper TP04PUB221, Society of Manufacturing Engineers, Dearborn, Michigan

Palmer JA, Jokiel B, Nordquist CD, Kast BA, Atwood CJ, Grant E, Livingston FJ, Medina F, Wicker RB (2006) Mesoscale RF relay enabled by integrated rapid manufacturing. Rapid Prototyping J 12(3):148–155. doi:10.1108/13552540610670726

Kataria A, Rosen DW (2000) Building around inserts: methods for fabricating complex devices in stereolithography. Proceedings of DETC 2000: ASME Design Engineering Technical Conferences and Computers and Information in Engineering Conference, DETC00/MECH-14206, Baltimore, Maryland, Sep. 10–13

De Laurentis KJ, Kong FF, Mavroidis C (2002) Procedure for rapid fabrication of non-assembly mechanisms with embedded components. Proceedings of DETC 2002: ASME 2002 Design Engineering Technical Conferences and Computers and Information in Engineering Conference, DETC2002/MECH-34350, Montreal, Canada, Sep. 29–Oct. 2

Navarrete M, Lopes A, Estrada R, Acuña J, Medina F, Palmer J, MacDonald E, Wicker RB (2007) Integrated layered manufacturing of a novel wireless motion sensor system with GPS. Proceedings of the 18th Annual Solid Freeform Fabrication Symposium, University of Texas at Austin, August 6–8

Lopes A, Navarrete M, Medina F, Palmer JA, MacDonald E, Wicker RB (2006) Expanding rapid prototyping for electronic systems integration of arbitrary form. Proceedings of the 17th Annual Solid Freeform Fabrication Symposium, University of Texas at Austin, August 14–16

Geving B, Kataria A, Moore C, Ebert-Uphoff I, Kurfess TR, Rosen DW (2000) Conceptual design of a generalized stereolithography machine. Proceedings of the 2000 Japan–USA Symposium on Flexible Automation, Ann Arbor, MI, July 23–26.

Inamdar A, Medina F, Magana M, Grajeda Y, Wicker RB (2006) Development of an automated multiple material stereolithography machine. Proceedings 17th Annual Solid Freeform Fabrication Symposium, University of Texas at Austin, August 14–16

Wicker RB, Medina F, Elkins CJ (2004) Multi material micro-fabrication: extending stereolithography to tissue engineering and other novel applications. Proceedings of the 15th Annual Solid Freeform Fabrication Symposium, University of Texas at Austin, August 2–4, pp 754–764

Hatanaka M, Cutkosky MR (2003) Process planning for embedding flexible materials in multi-material prototypes. Proceedings of DETC 2003: ASME Design Engineering Technical Conferences and Computers and Information in Engineering Conference, DETC2003/DFM-48166, Chicago, Illinois, Sep. 2–6

Wicker RB, Ranade A, Medina F, Palmer JA (2005) Embedded micro-channel fabrication using line-scan stereolithography. Assem Autom 25(4):316–329. doi:10.1108/01445150510626460

Chatwin CR, Farsari M, Huang S, Heywood MI, Young RCD, Birch PM, Claret-Tournier F, Richardson JD (1999) Characterisation of epoxy resins for microstereolithographic rapid prototyping. Int J Adv Manuf Technol 15(4):281–286. doi:10.1007/s001700050067

Sandoval JH, Wicker RB (2006) Functionalizing stereolithography resins: effects of dispersed multi-walled carbon nanotubes on physical properties. Rapid Prototyping J 5(12):292–303. doi:10.1108/13552540610707059

Sandoval JH, Ochoa L, Hernandez A, Lozoya O, Soto KF, Murr LE, Wicker RB (2005) Nanotailoring stereolithography resins for unique applications using carbon nanotubes. Proceedings of the Sixteenth Solid Freeform Fabrication, Austin, Texas, August 3–5

Saleh N, Hopkinson N, Hague RFM, Wise S (2004) Effects of electroplating on the mechanical properties of stereolithography and laser sintered parts. Rapid Prototyping J 10(5):305–315. doi:10.1108/13552540410562340

Liew CL, Leong KF, Chua CK, Du Z (2002) Dual material rapid prototyping techniques for the development of biomedical devices. Part 2: secondary powder deposition. Int J Adv Manuf Technol 19(9):679–687. doi:10.1007/s001700200113

Chockalingam K, Jawahar N (2006) Influence of layer thickness on mechanical properties in stereolithography. Rapid Prototyping J 12(2):106–113. doi:10.1108/13552540610652456

Chockalingam K, Jawahar N, Ramanathan KN, Banerjee PS (2006) Optimization of stereolithography process parameters for part strength using design of experiments. Int J Adv Manuf Technol 29(1–2):79–88. doi:10.1007/s00170-004-2307-0

Yang ZY, Chen YH, Sze WS (2001) Determining build orientation for layer-based machining. Int J Adv Manuf Technol 18(5):313–322. doi:10.1007/s001700170055

Byun HS, Lee KH (2006) Determination of optimal build direction in rapid prototyping with variable slicing. Int J Adv Manuf Technol 28(3–4):307–313. doi:10.1007/s00170-004-2355-5

Hague R, Mansour S, Saleh N, Harris R (2004) Materials analysis of stereolithography resins for use in rapid manufacturing. J Mater Sci 39:2457–2464. doi:10.1023/B:JMSC.0000020010.73768.4a

Dulieu-Barton JM, Fulton MC (2000) Mechanical properties of a typical stereolithography resin. Strain 36(2):81–87. doi:10.1111/j.1475-1305.2000.tb01177.x

Somos DSM (June 2004) WaterShed 11120—product data sheet. New Castle, DE. www.dsmsomos.com

American Society for Testing and Materials, Standard 638 (2005) Standard test method for tensile properties of plastics. Annual Book of ASTM Standards, West Conshohocken, PA

Montgomery DC (2001) Design and analysis of experiments, 5th edn. Wiley, New York, p 856

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Quintana, R., Choi, JW., Puebla, K. et al. Effects of build orientation on tensile strength for stereolithography-manufactured ASTM D-638 type I specimens. Int J Adv Manuf Technol 46, 201–215 (2010). https://doi.org/10.1007/s00170-009-2066-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2066-z