Abstract

Since the properties of wood significantly change with its moisture content, it is important to know the effect of different moisture conditions on wood. A brief summary is provided on this topic in the first part of this article. The compression along the wood grain is a modification resulting in better pliability. The moisture dependence of mechanical properties of longitudinally compressed wood is not known yet. For this purpose, the results in this article are considered as basic research results. Bending- and compression tests on beech specimens compressed longitudinally by 20% were carried out at different moisture contents. Changing moisture content has almost no significant effect on the modulus of rupture of wood that has been longitudinally compressed, compared to the sensitivity to changes in moisture content of untreated wood. However, the effect of moisture content on the change of bending modulus of elasticity, compressive strength parallel to the grain and bendability coefficient diverges significantly. As a result of these changes, there is a great difference in the pliability with different moisture contents of treated wood. For the best pliability during bending, the moisture content of longitudinally compressed wood must be close to its fiber saturation point.

Similar content being viewed by others

1 Introduction

Wood is a natural composite material, built up mainly of cellulose, hemicelluloses and lignin. These three components form the microstructure of cells (Da Silva and Kyriakides 2007). Cellulose chains have a slender shape, 4–5 μm long, and are arranged in bunches, called microfibrils (Gindl 2001; Tamer and Fauziah 2013). Hemicelluloses and lignin form the matrix of the cell walls, while cells are linked by the highly lignified middle lamella (Dinwoodie 1971; Gindl 2001; Inoue et al. 2008).

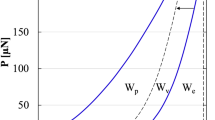

When the longitudinal compression of wood is combined with a thermo-hydro treatment, wood becomes more pliable. Prior to compression, the high-density and high quality hardwood (Buchter et al. 1993) has to be plasticized. The plasticization process means the softening of the bonds of hemicelluloses and lignin, so the binding force between cells and between microfibrils decreases. According to Lenth and Kamke (2001), increasing moisture content (MC) decreases the softening temperature of lignin and hemicelluloses. These are the reasons why softening of wood in hot and humid conditions is needed (Ansell 2012). During longitudinal compression, the specimen can be held for a predetermined time constantly at the applied compression level. This period has been called earlier relaxation, but a much more descriptive name is fixation, because the compressed length of the wood is fixated for a predetermined time. In this period, the stresses caused by the longitudinal compression of wood are relaxed and finally—depending on the duration of this period—the longitudinal deformation partially or completely remains after treatment. Fixation increases the effects of the longitudinal compression. Compression stress increases during the compression process and decreases continuously in the fixation phase with gradually decreasing intensity (Fig. 1). Since the rate of compression is constant in Fig. 1 (Báder and Németh 2018a), the shape of the strain–stress curve seems similar to the time-stress curve in the compression phase.

A typical time-stress graph of a longitudinal compression followed by a fixation for 5 min, based on Báder and Németh (2018a)

It is most important that the modulus of elasticity (MoE) further decreases along with increasing fixation time. The decrease in the MoE as a result of longitudinal compression is 59%. Its decrease due to compression followed by fixation for 1 min is 63%, and if fixation is used for more than 10 h after compression, the MoE decreases by 81%. Each value is with a uniform MC of 12% (Báder and Németh 2018a). In a previous study by Báder and Németh (2018a), a relationship was identified between compressive stress change during fixation, remaining shortening and some mechanical properties. Increasing fixation time increases the remaining shortening of the specimen, so its spring-back will be much weaker (Báder and Németh 2018a). The spring-back correlates well with the change of the compression stress during fixation, the MoE and the bendability. Fixation for a long time results in a more effective treatment, but it consumes much time. Thus, it may be used only if extreme wood properties are needed after this modification process. Considering the effective property changes, the productivity and the costs, the ideal fixation time was specified as 1 min by Báder and Németh (2018a), but it actually depends on the needs regarding the product properties.

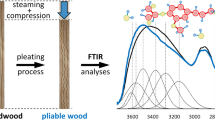

The method of longitudinal compression and fixation was called “pleating” due to the buckling of the cell walls by the treatment. The physical and mechanical properties of pleated wood are most affected by the compression ratio and the time of fixation. As evidenced by Báder and Németh (2017a), the self-developed laboratory compressing machine produces specimens with equal compression ratio along the length. Unequal compression ratio along the length befalls very rarely and if such a mistake occurs, it is clearly visible (Báder and Németh 2018a), so the investigation of the equal compression ratio along the length was not necessary in this study. After treatment, the specimen is first wet, and it should be dried after adjusting its shape and before its final use. Different minimal moisture contents can be found in the literature as a limit of pliability, ranging from 15% (Vorreiter 1949; Ivánovics 2005) to 25% (Buchter et al. 1993; Szabó 2002; Kamke 2014). Pleated wood with over 15% MC has nearly plastic properties. Between 0 and 5% MC, the treated wood is more brittle than untreated wood, so it is no longer pliable (Vorreiter 1949). Unfortunately, after shaping and drying, pleated wood only keeps its shape until it stays dry. If it is re-moistened, its original shape will be partially recovered, similar to what Inoue et al. (2008) and Kúdela et al. (2018) described as it has a high shrinkage-swelling in the longitudinal direction. The easiest way to decrease the swelling of wood is the reduction of its moisture uptake. This might be done using different treatments, for example heat treatment in different atmospheres or impregnation (Inoue et al. 2008; Obataya and Higashihara 2017; Báder and Németh 2018c).

The described modification method results in a semi-finished wood product, which can be used for many purposes, where pliable wood is needed. Analysing the bending tests of pleated wood showed that the bending force and the modulus of elasticity decrease exceedingly, and ensure a high deformability of the wood, compared to untreated specimens (Báder and Németh 2018a). The technology was first patented by Hanemann (1917), but industrial production began only in the second half of the 1920s (Báder and Németh 2018b). The most modern equipment used today has been patented in 1989 (Thomassen et al. 1991). Longitudinally compressed wood is currently produced in Italy, Hungary and in the USA (Báder and Németh 2018b). This is an excellent raw material for the furniture industry, interior design, or areas where sharp corners are not allowed for safety reasons (ship and aircraft furniture) (Báder 2015).

The water content of wood can be divided into two physically different parts. Bound water is found in the cell walls and bonded to the hydroxyl groups of the main components of wood (Berthold et al. 1996; Thygesen et al. 2010; Ansell 2011). The change in bonded MC is called sorption. Generally, the decrease in MC is called desorption, while water uptake is resorption or adsorption (Siau 1984). Equilibrium moisture content (EMC) can be achieved at a constant temperature and relative humidity (RH) of the air over time. Fiber saturation point (FSP) is defined as MC above which the physical and mechanical wood properties do not change because of changes in its MC (Stamm 1964; Glass and Zelinka 2010).

Plasticization reduces EMC of wood at the beginning of the desorption by 3.7% (MC%). This difference later decreases, while at EMC below 10%, all moisture contents are the same (Fig. 2). Pleating results in a deviation between 0% and 1% (MC%) of adsorption compared to control specimens. FSP is the same for treated and control wood after adsorption. Thus, the sorption isotherm of pleated wood in comparison with untreated wood differs only slightly (Báder and Németh 2017b).

Sorption isotherms of beech wood at the first desorption, based on Báder and Németh (2017b). BC control specimen, BSC steamed control specimen, B0m longitudinally compressed specimen, BLm longitudinally compressed and fixated for a long-time specimen

It has been well-known for a long time that MC affects not just the dimensions but also the physical and mechanical properties of wood (Huang et al. 2006; Hernández et al. 2014). Bauschinger published this fact in Munich in 1883, and many researchers dealt with this topic later, because of its practical and theoretical importance (Tiemann 1907; Vorreiter 1949; Kollmann 1951; Niemz and Sonderegger 2017). The change ratio is called coefficient of moisture dependence of the mechanical property, and is marked with α (Molnár 2004), B (Skaar 1988), E (Vorreiter 1949; Kollmann 1951) or K (Jiang et al. 2012). As a coefficient, α never has a unit of measurement. The moisture dependence of some mechanical properties can be seen in Table 1, and the moisture dependence of other mechanical properties in Online Resource 1.

The results of the various research studies in Table 1 do not match perfectly, but the trend is similar. The reasons for the differences are wood species, the number and selection of specimens, accuracy and sensitivity in MC and temperature or in data analysis. The mechanical properties of wood increase in some cases up to about 5–10% MC (Fig. 3a) (Kollmann 1951; Ansell 2011), compared to the oven-dry state (0% MC).

Further increasing the moisture content above 10% until the FSP, only decreases the mechanical properties (Tiemann 1907; Skaar 1988). Above FSP, the mechanical properties have a constant value (Fig. 3a). As described by Tiemann (1906), by increasing MC, the cell walls expand and as a result, fibrils move farther from each other. The structure loosens, and, as a consequence, the mechanical properties deteriorate. As described by Gerhards (1980), the conclusions drawn by different researchers differ in whether there is a linear (by Drow, Greenhill, James, Kitahara and Suematsu, Okohira, Sellevold, Tang and Hsu) or a more complicated (by Ishida, Leont’ev, Wilson) relationship between the MC and the mechanical properties, as shown in Fig. 3b.

Nowadays, prior to laboratory mechanical testing, the specimens are generally conditioned at a temperature of 20 °C and 65% RH, resulting in about 12% moisture content of wood (Gerhards 1980; Skaar 1988; EN 408:2010+A1 2012). In order to determine the sensitivity of the mechanical properties to MC change, the mechanical properties at 12% MC are selected as reference values (σ12). Then, a well-correlated linear section should be added to the curve obtained from the measurement results, and the α coefficient can be computed by the slope of this linear section (Eq. 1):

where \(\Delta \sigma /\Delta MC\) is the slope of the linear equation (Jiang et al. 2012). Based on the values of α, the mechanical properties of wood specimens can be calculated as described in Eq. 2, according to Kollmann and to different standards (Kollmann 1951; MSZ 6786 2004a, b, c; ISO 13061 2014a, c, etc.):

where \(\sigma_{MC}\) is a particular mechanical property and MC is the moisture content of the specimen at the time of measurement. α coefficient for untreated wood is determined as 0.04 for modulus of rupture, 0.01 for modulus of elasticity, and 0.04 for compressive strength (MSZ 6786-15 2004a, b, c). Using Eq. 2, data comparable to the evaluation of research results are obtained. The equation can be interpreted within a range of 12 ± 3% by Hungarian standard MSZ 6786-15 (2004a), but researchers usually give a much wider range (Vorreiter 1949; Kollmann 1951; Lohmann et al. 1987; Niemz 1993; Molnár 2004).

This study is aimed to gain a better understanding of the effect of MC on the selected physical and mechanical properties (bending modulus of elasticity, modulus of rupture, stress at 4 mm crosshead displacement, pliability and compressive strength parallel to grain) of pleated wood. The results will help to predict and calculate more precisely the mechanical and physical behavior, and as the most important property, the bending possibilities of pleated wood.

2 Materials and methods

2.1 Longitudinal compression and fixation

Beech specimens (Fagus sylvatica L.) came from the forests near Sopron, Hungary. The log was processed into boards and the freshly cut boards were cut into specimens with dimensions of 20 × 20 × 200 mm3 (radial × tangential × longitudinal directions), from the same trunk. The specimens were frozen until the time of use. All the wet specimens were randomly divided into 9 groups for the compression process, and each group contained 20 specimens. Each group contained specimens with sapwood, and randomly differing annual ring widths. During the treatment, the specimens were first plasticized by saturated steaming at atmospheric pressure, except for the control specimens (BC). Steamed control specimens (BSC) were also made to observe the possible modifying effect of the steaming process alone. The treated specimens (B1m) were additionally longitudinally compressed in a unique laboratory machine, inducing a 20% shortening compared to their original length with a compression rate of 50 mm·min−1. The fixation time was 1 min. The moisture content (MC) of the specimens at the time of the compression and fixation treatments was consistently above their fiber saturation point (FSP).

2.2 Conditioning

All examinations were made after drying and conditioning of the specimens at different temperatures and times to reach the necessary equilibrium moisture content (EMC), listed in Table 2.

The specimen groups BC, BSC and B1mD were dried in a Memmert 100–800 oven (Memmert GmbH, Germany) at 40 °C temperature for 24 h, while B1mB specimen group for 65 h. B1mA specimen group was dried at 40 °C temperature for 65 h, at 60 °C for 24 h, at 80 °C for 7 h and at 103 °C for 41 h. Specimen groups B1mE, B1mF and B1mG were stored in the conditioning room at 20 °C/65% RH for 45, 10 and 2 h, respectively. After these described drying processes, BC, BSC and B1mC specimen groups were put in the conditioning room for 117 days. The other specimens were divided into six groups based on their MC and put into lockable boxes, which do not let air exchange with the outside air. This way the specimens could equalize their moisture content for more than 100 days at a constant temperature of 20 °C, except for B1mF and B1mG specimens, because the risk of fungi degradation was higher due to the high MC.

To determine the MC, small pieces were prepared from each bending specimen after the bending tests, along with the compression test specimens. The weight of these specimens (mn) was measured with a Precisa XT 1220M-FR scale (Precisa Instruments AG., Switzerland), which measures grams to an accuracy of 3 decimal places. They were then dried in a Memmert 100–800 oven at 103 ± 2 °C according to MSZ 6786-2 (1988) and ISO 13061-1 (2014a), and then the absolute dry weight (m0) was measured. This way, the MC of the specimens could be calculated at the time of the mechanical tests, using below standardized weight measurement method equation from the mentioned standards (Eq. 3):

2.3 Bending test

Based on the method described by Báder and Németh (2018a), the height of the specimens (h) was cut back to 12.5 mm, while the width (b) was left in the original size. Control specimens were made for the bending test averaging 19.6 × 12.5 × 200.1 mm3 (R × T × L) and specimens for treatment were 19.6 × 12.5 × 195.2 mm3 (R × T × L). The annual rings were in a vertical direction during the bending examinations. A universal material testing machine (Instron 4208, Instron Corporation, USA) was used for 4-point bending tests, equipped with a static load cell of 300 kN maximum capacity. Each roller had a diameter of 30 mm. The loading rate was 8 mm·min−1 both for control and B1mA specimens and 20 mm min−1 for all other specimens because of the much higher pliability, according to the Hungarian standard MSZ 6786-5 (2004b) and to ISO 13061-1 (2014b). Tests were stopped upon failure, when the load dropped with no recovery. The 4-point bending test was chosen because the volume under stress is bigger than that under 3-point bending and thus, it gives a more relevant average result on the bending properties of wood (Hein and Brancheriau 2018). Moreover, the EN 408:2010 + A1 (2012) standard requires this measurement method. Thus, modulus of rupture (MoR) with 4-point bending test was determined at EMC by Eq. 4 according to EN 408:2010+A1 (2012):

where F is the maximum load, and a is the distance between the loading roller and the nearest support roller, in this case 50 mm. The upper span was 50 mm. Based on previous measurements by Báder and Németh (2018a), 4 mm is the crosshead displacement where only a small proportion of specimens breaks, but the bending stress is not negligible compared to the MoR. This way the bending stress values for untreated and treated specimens could be compared under the same conditions, using Eq. (4) to find out how much easier it is to bend pleated wood than untreated wood.

The bending modulus of elasticity (MoE) was calculated according to the work by Báder and Németh (2018a), using the crosshead displacement (Δw) corresponding to the difference between the 10% and 25% of the maximum load (ΔF) (Eq. 5):

where L is the lower span (150 mm). The highest deflection during bending test (ymax) came from Eq. 6 (Báder and Németh 2018a).

where w is the maximum crosshead displacement. Equation 6 is applicable to highly pliable materials. The bendability coefficient (kbend) is another comparative characteristic for the final evaluation of the pliability resulting from pleating and different moisture contents, which was calculated according to Gaff et al. (2015) (Eq. 7):

2.4 Compression test

For compression tests parallel to the grain, specimens 12 × 12 × 18 mm3 (R × T × L) were made using the end sections of the bending specimens, which were mechanically intact after the bending tests. The cross section-length ratio is the same as that defined in the standard. Compression test specimens 20 × 20 × 30 mm3 (R × T × L) were also made to compare the results of the specimens with different dimensions. Sixteen pieces were made both from control (BC) and compressed (B1m) specimens from the same raw material and the same way as described above, and conditioned at 20 °C and 65% RH. The fiber direction of each specimen was parallel to the compression force. Both tests and calculations were made according to Hungarian standard MSZ 6786-8 (2004c) and ISO 13061-17 (2014c). The Instron 4208 universal material testing machine was used to perform the compression tests. The loading rate was 3 mm min−1. Tests were stopped when the load stabilized during the continuous pressing. Compressive strength was determined at EMC by Eq. 8 according to the abovementioned standards:

Compressive strength was calculated using the maximum measured force (F). The compressive stress at proportional limit is defined as the maximum stress that a material can sustain and still exhibits no permanent distortion (Winandy and Rowell 2005). Graphically, it is the endpoint of the linear range of the stress–strain curve. Based on these, the compressive stress was calculated at the proportional limit too, using Eq. 8.

2.5 Fiber saturation point test

From the specimens of BC, BSC and B1mA groups, 1 mm thick specimens were prepared to determine the FSP of the wood materials, and the possible modifying effect of the treatments. The weight of oven-dried thin specimens was measured using a Sartorius 2007 MP6E scale (Sartorius GmbH, Germany) which measures grams to an accuracy of 4 decimal places. Then the specimens were conditioned in a desiccator containing saturated CuSO4 salt solution, which provides 97.6 ± 0.5% RH (Greenspan 1977). The desiccator was put in the conditioning room with a constant temperature of 20 °C for 5 months. The RH in the desiccator was continuously measured with a Testo 174H hygrothermograph (Testo SE & Co. KGaA, Germany) placed in the container. The RH of air in the first days was 96–99% in the desiccator, measured by the hygrothermograph. After a week, the RH increased to 99.6–99.9%, caused by the water-saturated salt solution. The specimens were weighed keeping their MC unchanged prior to measuring their weight, and FSP of each specimen was calculated using Eq. 3.

2.6 Statistical analysis

Dell Statistica version 13 software was used for statistical analysis. A one-way analysis of variance Fisher`s LSD test with probabilities for post hoc tests was used for comparative analyses of the different treatments (comparison of compression specimens with different sizes and finding relationships between different treatments and sample properties). The significance level was at p < 0.05. Statistical analysis of the differences between the treatment groups was made using a T test. Trend lines were based on the results of the measurements and the calculation of equivalence was made using Microsoft Excel 2010 software.

3 Results and discussion

The average fiber saturation point (FSP) for beech control specimens (BC) was 25.6 ± 0.6%. The FSP for control specimens of steamed beech (BSC) was 25.9 ± 0.4%, while the FSP for treated beech specimens (B1mA) was 25.4 ± 0.8%. The large difference of FSP from the published data (35.6%, Molnár 2004) could have been caused by drying the specimens to 0% moisture content (MC) at 103 °C temperature before saturating with water vapor, and the relative humidity (RH) slightly below 100% during the tests (Báder and Németh 2017b). The FSP of control and treated specimens is the same, about 25.6%. This result can also be proven by Fig. 4a, because there is a negligible change of mechanical properties when their MC is over 25% compared to their change below 25% MC. This confirms the correctness of the FSP test.

Change of some mechanical properties of pleated wood at different moisture contents (MC), compared to untreated specimens at 12% MC; the change of bending stress was measured at 4 mm crosshead displacement (a) and typical bending stress–strain curves of untreated (BC), steamed (BSC) and longitudinally compressed specimens at different MCs, marked only with the MC% (b)

According to Báder and Németh (2018a), the mechanical properties of wood due to the applied steaming before pleating do not change compared to control specimens. In this research, there was no statistical difference between BC and BSC specimen groups, which is also evidenced by Fig. 4b, showing some typical stress–strain curves of untreated and steamed specimens at 12% MC, and typical stress–strain curves of pleated specimens at each examined MC level. The slopes of pleated wood at the beginning of each graph decrease with increasing MC, representing the change of the MoE. The initially peaky graphs gradually become rounded, thus the ductility of the treated specimens increases with increasing MC (Hayden et al. 1965). The properties of pleated wood shown in Fig. 4a, b were analysed between 0% MC and FSP, because above this value the change of mechanical properties can be considered constant (Stamm 1964; Glass and Zelinka 2010).

Various data can be found in the literature for the bending modulus of rupture (MoR). Wagenführ (2007) found 78–110–117 MPa, Kretschmann (2010) measured 105 MPa, Meier (2016) established 110 MPa, and Niemz and Sonderegger (2017) found 95 MPa for beech wood. In this research, the MoR for the control specimens averaged 111.7 MPa. The differences can be explained by the different dimensions and the different length and height ratios (L·h−1) of the specimens, the different densities of wood specimens and the differences between 3-point and 4-point bending tests. Testing the MoR at 12% MC, it decreased by 19.2% due to longitudinal compression and fixation for a short time, compared to the control specimens (Fig. 4a). This is in agreement with the results of Báder and Németh (2018b) where the decrease in MoR was about 24%. As seen in the literature analysis, the MoR does not decrease at low moisture contents, until about 5% (Table 1 and Fig. 3a). The current tests produced about the same values for MoR at 2.4% and 9.2% MC, so it can be assumed that at around 5% MC, a maximum value can be found, in accordance with the published data (Kollmann 1951; Skaar 1988). Taking into account this finding, the change of MOR with the MC can be outlined (Fig. 5a), and the quadratic equation of the curve between 9% and 24% MC can be seen on the graph. A linear section was added to the curve obtained from the measurement results similarly to Jiang et al. (2012), taking into consideration that it functions only from 7% to 16% MC. The MC at room conditions rarely exceeds these values so this range is wide enough to correct the research results of MoR in daily wood testing, to get the standardized MoR at 12% MC. From the linear equation in Fig. 5a, it can be inferred that each 1% MC change results in an increase or decrease of 3.87 MPa for the MoR. Calculated in accordance with Eq. 1, the degree of change of the MoR for each percent MC change is α = 4.2.

Moisture content dependence of modulus of rupture (a), stress at 4 mm crosshead displacement (b), modulus of elasticity (c), bendability coefficient (d), compressive strength (e) and different deflection types during 4-point bending tests (f) of pleated wood. The curved lines are quadratic polynomials fitted to the data points; the fitting corresponds to the value of R2, while the straight lines and their associated first-degree equations are fitted to the quadratic polynomials. In f the dots and the thick straight line belong to the secondary vertical axis on the right

Comparing Figs. 3a and 5a, the shapes of the MoR graphs of untreated and pleated wood are very similar as well as their α coefficients (Table 1).

The other α coefficients were calculated in the same way. The value of the bending stress at 4 mm crosshead displacement for control specimens was 95.1 MPa at 12% MC, and it is approximately halved by pleating, as seen in Fig. 4a. The graph in Fig. 5b has a slight curve over the whole range between the absolute dry state and FSP. The used linear approximation results in a high α value of 5.4, based on Eq. 1. Thus, the force needed for bending wood decreases very much due to the increased MC of pleated wood (Figs. 4b, 5b).

The results by Wagenführ (2007) are 9.2–13.0–13.5 GPa, Kretschmann (2010) measured 12.3 GPa, Meier (2016) calculated 14.3 GPa, and Niemz and Sonderegger (2017) found 13.0 GPa for the bending modulus of elasticity (MoE) of beech wood. In this research, the MoE for the control specimens averaged 9.89 GPa. The differences can be explained by the setup deviations between the 3 and the 4-point bending tests, besides the natural variation of the wood even within one log. MoE was 5.34 GPa after the longitudinal compression and fixation for a short time which is a 46.0% decrease compared to the control values, both at 12% MC (Fig. 4a). Based on the results, a curve with a similar shape to the MoR graph can be drawn (Fig. 5c). A simpler variant can be obtained through the linear approximation, which shows an α value of 5.0 in the range between 6% and 17% MC. Compared to the published value of 1–2% (Table 1), this result shows significant changes. MoE and pliability are closely related (Ashby and Jones 2003). Using bendability coefficient (kbend) is a good possibility for pliability investigation. Comparing at 12% MC, kbend increases by 136% as a result of pleating. The graph in Fig. 5d has a slight curve. The α coefficient of the approximating linear line is 4.2 and it is valid between 2% and 22% MC. Increasing the MC, the kbend of pleated wood increased fourfold, while kbend of the treated specimens at 12% MC were already 2.4 times higher compared to control specimens at 12% MC. This means a great increase in pliability. As earlier described, increasing MC decreases the softening temperature of lignin and hemicelluloses, thus these constituents are more likely in their plasticized state when the MC is high. For example, Olsson and Salmén (2003) and Engelund et al. (2013) affirmed that the softening of hemicelluloses occurs at room temperature around 70–75% RH. These facts explain the much better pliability of wood besides high MC not only if it is pleated, but even when it is untreated.

In the 4-point bending tests at 12% MC, the deflection at maximum load and the highest deflection before breaking of control specimens averaged 7.3 and 7.6 mm, respectively. These deflections increased by 143% and 149% for pleated specimens, respectively. Figure 5e shows the deflection of the treated specimens and also shows that the deflection at the breaking point diverges from the deflection at the highest bending force with increasing MC (Y axis on the right side of Fig. 5f), so it is even more difficult to break the specimens. The specimens approach the plastic state with increasing MC, as Vorreiter (1949) described. The α coefficient of the deflection ability of pleated wood is 7.6 and valid from 5% MC up to FSP. Above the FSP, the MoE slightly reduces (Fig. 4a), but surprisingly, the deflection of specimens drops at the FSP, and above the FSP it becomes constant (Fig. 5f). Free water above the FSP reduces the available free void volume and causes hydraulic pressure during bending, which generates stresses in the material (Stevens and Turner 1948; Peck 1957). A good explanation can be that the appearance of hydraulic forces induced by free-water in the mostly stressed area results in rupture.

The decrease in the MoE between 12% MC and the FSP was 25% (MoE%), similar to that of fixation for a long time compared to the specimens with fixation for 1 min, which was 19% (MoE%), both at 12% MC (Báder and Németh 2018a). These results predict that the compressed material and that fixated for a short time in its wet state and the fixated for a long-time material at 12% MC have similar bending ability. The increase in the highest possible deflection between 12% MC and the FSP was 120%, but in the case of the fixation for a long time compared to the specimens with fixation for 1 min it was 320% (Báder and Németh 2018a). The change in pliability is not as extensive as indicated by the decrease in MoE, but 120% is still a very high increase. The fracture during bending usually occurs on the side under tension because wood allows much less tensional deformation compared to the compressed deformation (Gaff et al. 2015). Thus, the neutral axis has to be moved as close to the tension side as possible to avoid its breaking. The appearance of the high-tension stresses during bending can be delayed or even removed by generating buckled cell walls. The cell walls of wood fixated for a long time are much more buckled than the cell walls that were compressed without fixation or only fixated for a short time (Báder and Németh 2018a). The reason for the smaller pliability is because the specimens fixated for a short time cannot stretch as much on the tension side during bending. A greater compression ratio with fixation for a longer time solves this problem but this is a very time-consuming procedure. This solution can be substituted to a certain extent by using the longitudinally compressed wood in a wetter state. For best pliability, the moisture content of the pleated beech wood must be close to its FSP, between 15 and 25% MC.

The published data for compressive strength parallel to the grain (σc) of beech wood are 48–65–70 MPa (Wagenführ 2007), 51.3 MPa (Kretschmann 2010), 57.0 MPa (Meier 2016), and 52 MPa (Niemz and Sonderegger 2017). The current research results for the control specimens averaged 53.1 MPa, consistent with published values. The comparison of the specimens with 12 × 12 × 18 mm3 and 20 × 20 × 30 mm3 (R × T × L) resulted in no statistical difference in σc. This is also true for control and treated specimen groups. The average σc result for treated specimens at 12% MC is 49.9 MPa, which can be considered the same as the result for the control specimens (Fig. 4a). In the range between 0% and 17% MC, the α coefficient is 3.2 (Fig. 5e), which is about the half of the data given in the literature for untreated wood (Table 1). Moreover, the proportional limit obtained during the compression test for pleated wood is about one-third lower compared to the proportional limit of untreated specimens, and in many cases the elastic range cannot be determined, neither the compressive stress at proportional limit. This is a consequence of the longitudinal compression, because the wood has been compressed beyond its elasticity limit during the pleating process. However, this type of longitudinal compression cannot be considered as a compressive strength test, because it was made under special circumstances when the material was in plastified state.

4 Conclusion

In this study, comparative bending- and compression tests were carried out with longitudinally compressed beech wood specimens with different moisture contents. The mechanical properties of wood change with the moisture content and the ratio of change differs from the untreated specimens.

This study indicates that compressive strength parallel to the grain exhibits the smallest sensitivity to changes in moisture content by an α value of 3.2%, followed by 4.2% for its modulus of rupture, 5.0% for its modulus of elasticity and 5.4% for stress at a 4 mm crosshead displacement. With increasing moisture content, the α value of both the bendability coefficient and the highest deflection during a 4-point bending test causes an increase of 4.2% and 7.6%, respectively. As a result of the research, it can be deduced that there is a negligible difference between the change of the modulus of rupture of the untreated and the treated wood due to the change in their moisture content. However, the changes of modulus of elasticity, bendability coefficient and compressive strength show a considerable alteration. For the best pliability during bending, the moisture content of pleated wood must be close to its fiber saturation point.

References

Ansell MP (2011) Wood—a 45th anniversary review of JMS papers. Part 1: the wood cell wall and mechanical properties. J Mater Sci 46:7357–7368. https://doi.org/10.1007/s10853-011-5856-2

Ansell MP (2012) Wood: a 45th anniversary review of JMS papers: part 2. Wood modification, fire resistance, carbonization, wood–cement and wood–polymer composites. J Mater Sci 47:583–598. https://doi.org/10.1007/s10853-011-5995-5

Ashby MF, Jones DRH (2003) Engineering materials 1—an introduction to their properties and applications, 2, reprinted edn. Butterworth-Heinemann, Oxford

Báder M (2015) Practical issues of longitudinally compressed wood—part 3: mechanical properties and areas of application of compressed wood. Faipar 63:52–65. https://doi.org/10.14602/WOODSCI.2015.2.53 (in Hungarian)

Báder M, Németh R (2017a) Research conditions of the wood’s longitudinal compression—part 3. J Gradus 4:419–425 (in Hungarian)

Báder M, Németh R (2017b) Hygroscopicity of longitudinally compressed wood. Acta Silv et Lignaria Hungarica 13:135–144. https://doi.org/10.1515/aslh-2017-0010

Báder M, Németh R (2018a) The effect of the relaxation time on the mechanical properties of longitudinally compressed wood. Wood Res 63:383–398

Báder M, Németh R (2018b) The effect of the rate of longitudinal compression on selected wood properties. Acta Silv et Lignaria Hungarica 14:83–92. https://doi.org/10.2478/aslh-2018-0005

Báder M, Németh R (2018c) Production technology and properties of longitudinally compressed wood. In: Zupcic I, Spanic N (eds) Proceedings of the 29th international conference on wood science and technology, Zagreb, pp 35–43

Berthold J, Rinaudo M, Salmén L (1996) Association of water to polar groups; estimations by an adsorption model for ligno-cellulosic materials. Colloids Surf A 112:117–129

Buchter J, Adelhoej J, Ljoerring J, Hansen O (1993) Introducing compressed wood. Danish Technological Institute, Department of Wood and Furniture, Taastrup

Da Silva A, Kyriakides S (2007) Compressive response and failure of balsa wood. Int J Solids Struct 44:8685–8717. https://doi.org/10.1016/j.ijsolstr.2007.07.003

Dinwoodie JM (1971) Wood. Composites 2:170–172

EN 408:2010 + A1 (2012) Timber structures—structural timber and glued laminated timber—determination of some physical and mechanical properties. Standard, European Committee for Standardization (CEN)

Engelund ET, Thygesen LG, Callum SS, Hill AS (2013) A critical discussion of the physics of wood–water interactions. Wood Sci Technol 47:141–161

Gaff M, Gašparík M, Borůvka V, Haviarová E (2015) Stress simulation in layered wood-based materials under mechanical loading. Mater Des 87:1065–1071. https://doi.org/10.1016/j.matdes.2015.08.128

Gerhards CC (1980) Effect of moisture content and temperature on the mechanical properties of wood: an analysis of immediate effects. Wood Fiber 14:4–36

Gindl W (2001) The effect of lignin on the moisture-dependent behavior of spruce wood in axial compression. J Mater Sci Lett 20:2161–2162

Glass SV, Zelinka SL (2010) Moisture relations and physical properties of wood. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison

Greenspan L (1977) Humidity fixed points of binary saturated aqueous solutions. J Res Natl Bur Stand A Phys Chem 81:89–96

Hanemann M (1917) Wood treatment processes. Deutsches Reich Reichspatentamt, Patent Nr. 318197:1 (in German)

Hayden HW, Moffatt WG, Wulff J (1965) The structure and properties of materials. Vol. III: Mechanical behavior. Wiley, New York

Hein PRG, Brancheriau L (2018) Comparison between three-point and four-point flexural tests to determine wood strength of Eucalyptus specimens. Maderas Ciencia y Tecnología 20:333–342. https://doi.org/10.4067/S0718-221X2018005003401

Hernández RE, Passarini L, Koubaa A (2014) Effects of temperature and moisture content on selected wood mechanical properties involved in the chipping process. Wood Sci Technol 48:1281–1301. https://doi.org/10.1007/s00226-014-0673-9

Huang S-H, Cortes P, Cantwell WJ (2006) The influence of moisture on the mechanical properties of wood polymer composites. J Mater Sci 41:5386–5390. https://doi.org/10.1007/s10853-006-0377-0

Inoue M, Sekino N, Morooka T, Rowell RM, Norimoto M (2008) Fixation of compressive deformation in wood by pre-steaming. J Trop For Sci 20:273–281

ISO 13061-1 (2014a) Physical and mechanical properties of wood—test methods for small clear wood specimens—part 1: determination of moisture content for physical and mechanical tests. Standard, International Organization for Standardization (ISO)

ISO 13061-3 (2014b) Physical and mechanical properties of wood—test methods for small clear wood specimens—part 3: determination of ultimate strength in static bending. Standard, International Organization for Standardization (ISO)

ISO 13061-17 (2014c) Physical and mechanical properties of wood—test methods for small clear wood specimens—part 17: determination of ultimate stress in compression parallel to grain. Standard, International Organization for Standardization (ISO)

Ivánovics G (2005) The technology of wood bending nowadays. In: Danyi J, Lévai P, Csabai MLS, Fehér MNI (eds) College of Kecskemét, Hungary, pp 189–193 (in Hungarian)

Jiang Z, Wang H, Tian G, et al (2012) Sensitivity of several selected mechanical properties of moso bamboo to moisture content change under fiber saturation point. In: Herian VL (ed) Proceedings of the 55th international convention of society of wood science and technology, Beijing, pp 763–774

Kamke FA (2014) Modified wood for new product opportunities. In: Presentation at the joint EWPAA-FWPA symposium. Engineered wood products—from here to the future, Marriott Resort, Gold Coast, p 28

Kollmann FFP (1951) Technology of woods and wood materials. Springer, Berlin (in German)

Kollmann FFP, Coté WA (1968) Principles of wood science and technology—I—solid wood. Springer, New York

Kretschmann DE (2010) Mechanical properties of wood. In: Ross RJ (ed) Wood handbook—wood as an engineering material. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison, p 508

Kúdela J, Rousek R, Rademacher P, Rešetka M, Dejmal A (2018) Influence of pressing parameters on dimensional stability and density of compressed beech wood. Eur J Wood Prod 76:1241–1252. https://doi.org/10.1007/s00107-018-1298-8

Lenth CA, Kamke FA (2001) Moisture dependent softening behavior of wood. Wood and Fiber Sci 33:492–507

Lohmann U, Annies T, Ermschel D (1987) Wood-Handbook, 3, völlig überarb. DRW-Verl, Leinfelden-Echterdingen (in German)

Meier E (2016) European beech. In: The wood database. http://www.wood-database.com/european-beech/. Accessed 20 Jan 2018

Molnár S (2004) Wood material knowledge. Mezőgazdasági Szaktudás Kiadó, Budapest (in Hungarian)

MSZ 6786-2 (1988) Wood testing. Determination of moisture content. Standard, Hungarian Standards Institution (MSZT) (in Hungarian)

MSZ 6786-15 (2004a) Testing of wood materials. Determination of the modulus of elasticity in static bending. Standard, Hungarian Standards Institution (MSZT) (in Hungarian)

MSZ 6786-5 (2004b) Testing of wood materials. Determination of static bending strength. Standard, Hungarian Standards Institution (MSZT) (in Hungarian)

MSZ 6786-8 (2004c) Testing of wood materials. Determination of compression strength along the grain. Standard, Hungarian Standards Institution (MSZT) (in Hungarian)

Niemz P (1993) Physics of wood and wood-based materials. DRW-Verl, Leinfelden-Echterdingen (in German)

Niemz P, Sonderegger WU (2017) Wood physics: physics of wood and wood-based materials. Fachbuchverlag Leipzig im Carl Hanser Verlag, München (in German)

Obataya E, Higashihara T (2017) Reversible and irreversible dimensional changes of heat-treated wood during alternate wetting and drying. Wood Sci Technol 51:739–749. https://doi.org/10.1007/s00226-017-0918-5

Olsson AM, Salmén L (2003) The softening behavior of hemicelluloses related to moisture. In: Gatenholm P, Tenkanen M (eds) Hemicelluloses: science and technology. ACS Symposium Series, Washington, pp 184–197

Peck EC (1957) Bending solid wood to form. U.S. Department of Agriculture, Forest Service, Washington

Siau JF (1984) Transport processes in wood. Springer, Berlin

Sitkei G (ed) (1994) Theory of woodworking operations. Mezőgazdasági Szaktudás Kiadó, Budapest (in Hungarian)

Skaar C (1988) Wood-water relations. Springer, Berlin

Stamm AJ (1964) Wood and cellulose science. Ronald Press, New York

Stevens WC, Turner N (1948) Solid and laminated wood bending. Forest Products Research Laboratory, Department of Scientific and Industrial Research. His Majesty’s Stationery Office, London

Szabó I (2002) Wood bending. In: Molnárné PP (ed) Faipari kézikönyv II. Faipari Tudományos Alapítvány, Sopron, pp 60–61 (in Hungarian)

Tamer AT, Fauziah AA (2013) Cellulose microfibril angle in wood and its dynamic mechanical significance. In: van De Ven T, Godbout L (eds) Cellulose—fundamental aspects. Rijeka, Croatia, pp 113–142

Thomassen T, Ljorring J, Hansen O (1991) A method and apparatus for compressing a wood sample. World Intellectual Property Organization, Patent Nr. WO91/02637, p 24

Thygesen LG, Tang Engelund E, Hoffmeyer P (2010) Water sorption in wood and modified wood at high values of relative humidity. Part I: results for untreated, acetylated, and furfurylated Norway spruce. Holzforsch 64:315–323. https://doi.org/10.1515/hf.2010.044

Tiemann HD (1906) Effect of moisture upon the strength and stiffness of wood. U.S. Department of Agriculture, Washington

Tiemann HD (1907) The strength of wood as influenced by moisture. U.S. Department of Agriculture, Washington

Vorreiter L (1949) Woodtechnologycal handbook, vol I. Georg Fromme & Co., Wien (in German)

Wagenführ R (2007) Atlas of wood, 6. neu bearb. und erw. Aufl. Fachbuchverl. Leipzig im Hanser Verl, Leipzig (in German)

Winandy JE, Rowell RM (2005) Chemistry of wood strength. In: Rowell RM (ed) Handbook of wood chemistry and wood composites. CRC Pres, Boca Raton, p 485

Acknowledgements

Open access funding was provided by University of Sopron (SOE). This work was supported by the Széchenyi2020 Program, European Union, and European Social Fund (Grant Number EFOP-3.6.2-16-2017-00018). We are grateful to Anna Báder, a graduate student in timber engineering, for her assistance in measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest, related to this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Báder, M., Németh, R. Moisture-dependent mechanical properties of longitudinally compressed wood. Eur. J. Wood Prod. 77, 1009–1019 (2019). https://doi.org/10.1007/s00107-019-01448-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-019-01448-1