Abstract

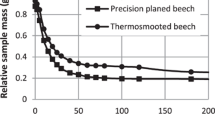

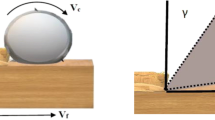

The application of water-based finishes to wood surfaces is known to increase surface roughness by raising the grain. This phenomenon is detrimental in the appearance of the finished wood surface. To eliminate it, light denibbing is needed prior to applying the second coat of finish. The objective of this study is to optimize wood machining to minimize raised grain caused by water-based coatings and to avoid, or at least, to minimize the sanding operation between each coat of finish. Experiments were done on beech samples. Complete experimental design was defined to generate several surface qualities from “smooth” to “rough” which are linked to the average thickness of the removed chips. The planing parameters were the cutting mode, cutting direction, feed speed, and rotation speed. To compare with existing practices in joinery industries, specimens were also sanded. Two layers of water based coating were applied. Half of the samples were sanded after the first coat and the other half were not. Following each coat, surface roughness was measured and raised grain was evaluated through tactile tests. Results show that sanding operation is responsible for more raised grain than planing. Whereas for planing, high chip removal thickness gives more raised grain after coating application. The effects of the other parameters on raised grain occurence are not found to be statistically significant. The average roughness (Sa), quadratic mean roughness (Sq), reduced peak height (Spk) and the material volume of the peak section (Vmp) are the roughness parameters best correlated with tactile evaluation of grain raising, but the correlations are weak.

Similar content being viewed by others

References

Arnold M (2010) Planing and sanding of wood surfaces. Effects on surface properties and coating performance (Congress Papers No. 32). Amsterdam, p 12

Aydin I (2004) Activation of wood surfaces for glue bonds by mechanical pre-treatment and its effects on some properties of veneer surfaces and plywood panels. Appl Surf Sci 233(1–4):268–274

Bhatti P, Newcomer L, Onstad L, Teschke K, Camp J, Morgan M, Vaughan TL (2011) Wood dust exposure and risk of lung cancer. Occup Environ Med 68:599–604

Blateyron F (2006) 3D parameters and new filtration techniques for surface metrology. In: Proceedings of the Japan Society of Precision Machining Spring General Meeting, pp 21–27

Brazier JD, Franklin GL (1961) Identification of hardwoods: a microscope key, forest products research bulletin. H.M. Stationery Office, Oxford

Cool J, Hernández R (2011) Performance of three alternative surfacing processes on black spruce wood and their effects on water-based coating adhesion. Wood Fiber Sci 43:365–378

De Meijer M (2001) Review on the durability of exterior wood coatings with reduced VOC-content. Prog Org Coat 43:217–225

De Moura L, Hernández R (2006) Effects of abrasive mineral, grit size and feed speed quality sanded surface of sugar maple wood. Wood Sci Technol 40:517–530

Evans P (2009) Reducing grain raising during the finishing of wood with water-based coatings. University of British Columbia, Vancouver, p 54 (cited by Landry et al. 2013)

Eyma F (2002) Characterization of cutting forces of different wood species with their mechanical properties. PhD thesis, Ecole Nationale Supérieure des Technologies et Industries du Bois, Epinal, France, p 177

Fujiwara Y, Fujii Y, Sawada Y, Okumura S (2001) Development of a parameter to reflect the roughness of a wood surface that corresponds to tactile roughness. A novel filter to exclude local valley effects. Holz Roh Werkst 59(5):351–355

Gindl M, Reiterer A, Sinn G, Stanzl-Tschegg SE (2004) Effects of surface ageing on wettability, surface chemistry, and adhesion of wood. Holz Roh Werkst 62(4):273–280

Gregersen P, Klausen H, Elsnab CU (1987) Chronic toxic encephalopathy in solvent-exposed painters in Denmark 1976–1980: clinical cases and social consequences after a 5-year follow-up. Am J Ind Med 11:399–417

Hancock DG, Langley ME, Chia KL, Woodman RJ, Shanahan EM (2015) Wood dust exposure and lung cancer risk: a meta-analysis. Occup Environ Med 72(12):889–898

INRS (2001) Design of capture devices on woodworking machines. INRS, Paris

ISO (2012) 25178-2, Geometrical product specification (GPS)—surface texture: areal—Part 2: Terms, definitions and surface

Koch P (1964) Wood machining processes. The Ronald Press Company, NewYork

Koehler A (1932) Some observations on raised grain. Trans ASME J Appl Mech 54:27–30

Koehler A (1955) Raised, loosened, torn, chipped, and fuzzy grain in lumber (No. 2044). Forest Products Laboratory, Madison

Landry V, Blanchet P, Cormier LM (2013) Water-based and solvent-based stains: impact on the grain raising in Yellow Birch. BioResources 8:1997–2009

Larricq P, Ramananantoandro T, Bacou M, Eterradossi O (2004) Two compared analyses of roughness on sanded surfaces: how to replace sensorial measure by mechanical measure?. In: Proceedings of the 2nd international symposium on wood machining, properties of wood and wood composites related, Vienna, Austria, pp 367–375

Marra GG, Syracuse NY (1932) An analysis of the factors responsible for raised grain on the wood of oak following sanding and staining. Trans ASME J Appl Mech: 177–185

Outahyon A (2008) Influences des paramètres d’usinage et de stockage sur les propriétés fonctionnelles des surfaces de bois de Douglas (Influence of machining and storage parameters on the functional properties of Douglas wood surfaces), (In French) PhD thesis, Ecole Nationale Supérieure d’Arts et Métiers, Cluny, France

Rajemison AH (2013) Proposal of alternative species to precious wood through the knowledge of the wood properties: the case of Madagascar Rosewood—application in furniture. Dissertation, University of Toulouse III, France and University of Antananarivo, Madagascar

Ramananantoandro T, Larricq P, Eterradossi O (2014) Relationships between 3D roughness parameters and visuotactile perception of surfaces of maritime pinewood and MDF. Holzforsch 68:93–101

Singh AP, Dawson BSW, Hands KD, Ward JV, Greaves M, Turner JCP, Rickard CL (2010) The anatomy of raised grain on Pinus radiate weatherboards. IAWA Bull 31(1):67–76

Sinn G, Sandak J, Ramananantoandro T (2009) Properties of wood surfaces—characterisation and measurement. A review COST Action E35 2004–2008: wood machining—micromechanics and fracture. Holzforsch 63:196–203

SMTF (2011) Recommendations for medical and professional supervision of workers exposed to the carcinogenic effects of wood dust. Arch Mal Prof Environ 72:119–172

Sogutlu C (2010) The effect of the feeding direction and feeding speed of planing on the surface roughness of Oriental beech and Scotch pine woods. Wood Res 55(4):67–78

Taylor JB, Carrano AL, Lemaster RL (1999) Quantification of process parameters in a wood sanding operation. For Prod J 49:41–46

Acknowledgements

We are grateful to Schlumberger foundation for funding this project. Our sincere thanks go to Dr. Hervé Duchauffour and the French Embassy in Madagascar for granting a scholarship to finalize the article in France and to Pr. Eric Le Gal La Salle for allowing us to use the roughness measurement device at Institut Catholique d’Arts et Métiers (ICAM) Nantes. Authors thank Ms. Miora F. Ramanakoto (IUT Tarbes/ESSA-Forêts) for her help in tactile evaluation of grain raising and M. Andriambelo R. Razafimahatratra (ESSA-Forêts) for his assistance with R software.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ramananantoandro, T., Eyma, F., Belloncle, C. et al. Effects of machining parameters on raised grain occurring after the application of water-based finishes. Eur. J. Wood Prod. 76, 1323–1333 (2018). https://doi.org/10.1007/s00107-017-1250-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-017-1250-3