Abstract

European hardwood species such as beech, oak and ash present a potential alternative to commonly used softwoods in glued engineered wood products. To date, mainly amino- and phenoplast adhesives are used for bonding these hardwoods, but some one-component polyurethane (1C-PUR) adhesives prove to offer an alternative when combined with a primer pretreatment. Therefore, a study was conducted to examine the influences of primer treatment and other parameters, such as surface machining and press time on the bondability of ash, beech, oak and—as a reference—Norway spruce. Delamination and block shear tests were conducted according to current European standards. Furthermore, information about bonding quality was gathered by means of microscopic glue line thickness measurements. The results suggest that the primer treatment is able to significantly enhance the bonding quality of hardwoods. The choice of the surfacing method causes some significant changes in the primer effectiveness. However, not all species were equally affected. The influence of the primer treatment on shear tests in a dry state was rather low throughout the series and only little significance was found. similar results were found after variations of the press time.

Similar content being viewed by others

References

Aicher S, Ohnesorge D (2011) Shear strength of glued laminated timber made from European beech timber. Eur J Wood Prod 69(1):143–154

Aicher S, Reinhardt HW (2007) Delamination characteristics and shear strength of glued redheart beech lamellas [Delaminierungseigenschaften und Scherfestigkeiten von verklebten rotkernigen Buchenholzlamellen]. Holz Roh Werkst 65(2):125–136

Aicher S, Höfflin L, Behrens W (2001) A study on tension strength of finger joints in beech timber laminations. Otto-Graf-J 12:169–186

Bernasconi A (2004) Gluing of hardwood for supporting construction elements. [Verleimung von Laubholz für den tragenden Einsatz]. Schweiz Z Forstwes. 155(12):533–539

Blaß HJ, Denzer J, Freese M, Glos P, Linsenmann P (2005) Bending strength of glued laminated timber from beech wood. [Biegefestigkeit von Brettschichtholz aus Buche]. Research report of KIT Steel & Lightweight Structures Research Center for Steel, Timber & Masonry

Brandmair A, Clauß S, Haß P, Niemz P (2012) Gluing of hardwoods with 1C-PUR-adhesives for engineered wood elements. [Verklebung von Laubhölzern mit 1 K-PUR-Klebstoffen für den Holzbau]. Bauphysik 34(5):210–216

Clauß S, Dijkstra DJ, Gabriel J, Kläusler O, Matner M, Meckel W, Niemz P (2011) Influence of the chemical structure of PUR prepolymers on thermal stability. Int J Adhes Adhes 31(6):513–523

Cool J, Hernández R (2011) Evaluation of four surfacing methods on black spruce wood in relation to poly(vinyl acetate) gluing performance. Wood Fiber Sci 43(2):194–205

Davis G (1997) The performance of adhesive systems for structural timbers. Int J Adhes Adhes 17(3):247–255

de Moura LF, Cool J, Hernández E (2010) Anatomical evaluation of wood surfaces produced by oblique cutting and face milling. IAWA J 31(1):77

DIBt (2009) General technical approval Z-9.1-679. Glulam from beech and glulam from beech-hybrid. [BS-Holz aus Buche und BS-Holz Buche-Hybridträger]. Studiengemeinschaft Holzleimbau e.V, Germany

DIBt (2012) General technical approval Z-9.1-704. VIGAM glulam from oak wood. [VIGAM Brettschichtholz aus Eiche]. Elaborados y Fabricados Gamiz S.A

EN 15416 (2006) Adhesives for load bearing timber structures other than phenolic and aminoplastic—test methods—part 5: determination of conventional pressing time. European committee for standardization, Brussels

EN 15425 (2008) Adhesives—one component polyurethane for load bearing timber structures—classification and performance requirements. European committee for standardization, Brussels

EN 16254 (2013) Adhesives—emulsion polymerized isocyanate (EPI) for load-bearing timber structures—classification and performance requirements. European committee for standardization, Brussels

EN 392 (1997) Glued laminated timber—shear test of glue lines. European committee for standardization, Brussels

EN 391 (2001) Glued laminated timber—delamination test of glue lines. European committee for standardization, Brussels

EN 386 (2001) Glued laminated timber—performance requirements and minimum production requirements

EN 301 (2013) Adhesives, phenolic and aminoplastic, for load-bearing timber structures—classification and performance requirements. European committee for standardization, Brussels

EN 302-2 (2013) Adhesives for load-bearing timber structures - Test methods - Part 2: Determination of resistance to delamination. European committee for standardization, Brussels

Follrich J, Hansmann C, Teischinger A, Müller U (2007) Tensile strength of softwood butt end joints. Part 2: improvement of bond strength by a hydroxymethylated resorcinol primer. Wood. Mat Sci Eng 2(2):90–95

Frihart CR (2004) Adhesive interactions with wood. In: Winandy JE, Kamke FA (eds) Fundamentals of composite processing: Proceedings of a workshop, Madison, WI, 2004. General Technical Report FPL-GTR-149. US Department of Agriculture, Forest Service, Forest Products Laboratory, pp 118

Frühwald A, Ressel J, Becker P, Pohlmann C, Wonnemann R (2003) Use of hardwood for the production of glued laminated elements. [Verwendung von Laubhölzern zur Herstellung von Leimholzelementen]. Abschlussbericht Universität, Hamburg

Heisel U, Tröger J (1991) Aspects of face milling. [Betrachtungen zum Stirnplanfräsen]. Die Holzbearbeitung 38(10):44–51

Hernández R, Cool J (2008) Evaluation of three surfacing methods on paper birch wood in relation to water- and solvent-borne coating performance. Wood Fiber Sci 40(3):459–469

Kägi A, Niemz P, Mandallaz D (2006) Influence of moisture content and selected technological parameters on the adhesion of one-part polyurethane adhesives under extreme climatical conditions. [Einfluss der Holzfeuchte und ausgewählter technologischer Parameter auf die Verklebung mit 1K-PUR Klebstoffen unter extremen klimatischen Bedingungen]. Holz Roh Werkst 64(4):261–268

Kamke F, Lee J (2007) Adhesive Penetration in Wood—a Review. Wood Fiber Sci 39(2):205–220

Kläusler O, Clauß S, Lübke L, Trachsel J, Niemz P (2013) Influence of moisture on stress—strain behaviour of adhesives used for structural bonding of wood. Int J Adhes Adhes 44:57–65

Knorz M, Schmidt M, Torno S, van de Kuilen J-W (2014) Structural bonding of ash (Fraxinuns excelsior L.): resistance to delamination and performance in shearing tests. Eur J Wood Prod 72:297–309

Krackler V, Keunecke D, Niemz P (2010) Processing and uses of hardwood and hardwood residues. [Verarbeitung und Verwendungsmöglichkeiten von Laubholz und Laubholzresten]. ETH Zürich, Institute von Building materials, Wood physics, Zurich

Lehringer C, Gabriel J (2014) Review of recent research activities on one-component pur-adhesives for engineered wood products. In: Aicher S, Reinhardt HW, Garrecht H (eds) Materials and joints in timber structures, vol 9., RILEM BookseriesSpringer, Netherlands, pp 405–420

López-Suevos F, Richter K (2009) Hydroxymethylated resorcinol (HMR) and novolak-based HMR (n-HMR) primers to enhance bond durability of Eucalyptus globulus glulams. J Adhes Sci Technol 23:1925–1937

Marra A (1992) Technology of wood bonding: principles in practice. Van Nostrand Reinhold, New York

Müller U, Veigel S, Follrich J, Gabriel J, Gindl W (2009) Performance of 1C polyurethane in comparison to other wood adhesives. Paper presented at the ICWA 09 International Conference on Wood Adhesives, Lake Tahoe, Nevada, 28–30. September 2009

Ohnesorge D (2009) Bonding properties of glued laminated timber made of beech: Studies on the improvement of the adhesive joint strength and adhesive joint resistance of glulam made of redheart and not redheart beech wood. [Verklebungseigenschaften von Brettschichtholz aus Buche: Untersuchungen zur Verbesserung der Klebefugenfestigkeit und Klebefugenbeständigkeit von Brettschichtholz aus rotkernigem und nicht rotkernigem Buchenholz (Fagus sylvatica L.)], vol 43. Series of Institute for forestry research, Freiburg, Baden-Wuerttemberg

Ohnesorge D, Henning M, Becker G (2009) Importance of hardwood in the glulam production. [Bedeutung von Laubholz bei der Brettschichtholzherstellung]. Holztechnologie 6:47–49

Ohnesorge D, Richter K, Becker G (2010) Influence of wood properties and bonding parameters on bond durability of European Beech (Fagus sylvatica L.) glulams. Ann For Sci 67(6):601

Pitzner B, Bernasconi A, Frühwald A (2001) Bonding of indigenous durable species to secure market shares in outdoor application. [Verklebung einheimischer dauerhafter Holzarten zur Sicherung von Marktbereichen im Außenbau]. Work report. Hamburg

Pizzi A, Mittal KL (2003) The handbook of adhesive technology. Dekker, New York

Pöhler E, Klingner R, Künniger T (2006) Beech (Fagus sylvatica L.)—Technological properties, adhesion behaviour and colour stability with and without coatings of the red heartwood. Ann For Sci 63:129–137

Schmidt M, Glos P, Wegener G (2010) Gluing of beech wood for engineered wood products. [Verklebung von Buchenholz für tragende Holzbauteile]. Eur J Wood Prod 68(1):43–57

Singh AP, Anderson CR, Warnes JM, Matsumura J (2002) The effect of planing on the microscopic structure of Pinus radiata wood cells in relation to penetration of PVA glue. Holz Roh Werkst 60(5):333–341

Stehr M, Gardner DJ, Wålinder MEP (2001) Dynamic wettability of different machined wood surfaces. J Adhes 76(3):185–200

Tröger J, Enßle M (2008) Studies on the cone face milling and face milling at the Institute for Machine Tools, University of Stuttgart. [Untersuchungen zum Kegelstirnplanfräsen und Stirnplanfräsen am Institut für Werkzeugmaschinen der Universität Stuttgart]. Holz Roh Werkst 66(2):155–156

Vick CB, Okkonen EA (2000) Durability of one-part polyurethane bonds to wood improved by HMR coupling agent. Forest Prod J 50(10)

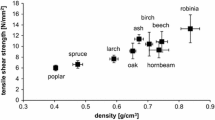

Wagenführ R (2007) Holzatlas, vol 6. Fachbuchverlag Leipzig im Hanser-Verlag, München

Wetzig M (2009) Studies on the optimization of bonding hardwoods. [Untersuchungen zur Optimierung der Verklebung von Laubholz]. Diploma Thesis, ETH Zurich, Institute for Building materials and wood physics., University of Cooperative Education Sachsen, Dresden

Wetzig M, Haß P, Niemz P, Hänsel A (2011) Investigation on bonding of three-layer cross laminated timber using hardwood [Untersuchungen zur Verklebung dreischichtiger Massivholzplatten unter Verwendung von Laubholz]. Bautechnik 88(10):687–693

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luedtke, J., Amen, C., van Ofen, A. et al. 1C-PUR-bonded hardwoods for engineered wood products: influence of selected processing parameters. Eur. J. Wood Prod. 73, 167–178 (2015). https://doi.org/10.1007/s00107-014-0875-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-014-0875-8