5

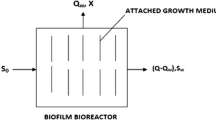

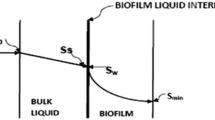

Mass transfer within microbial films is described using Monod type biological kinetics in terms of the properties of packing material and the feed solution. For this purpose computer techniques have been first developed for the numerical evaluation of the normalized biofilm mathematical model. A second-order partial differential equation describing the mechanism of dispersion phenomena inside the liquid layer is then solved to determine the mass transfer coefficient. The application of the theory to experimental data reported in literature has also been demonstrated using the values of mass transfer coefficients and the computer programs developed.

Similar content being viewed by others

Abbreviations

- A :

-

cross-sectional area, L2

- B :

-

dimensionless substrate concentration

- Bs :

-

dimensionless substrate concentration at the liquid-biofilm interface

- Bso :

-

lower limit in the definite integral Z calculated using Eq. (31)

- Bo :

-

dimensionless effluent substrate concentration corresponding to Bso

- b :

-

total width of parallel planes in conceptual model, L

- c:

-

bulk liquid phase substrate concentration, ML-3

- Co :

-

bulk liquid phase effluent substrate concentration, ML-3

- cs :

-

substrate concentration at the liquid-biofilm interface, ML-3

- cx :

-

substrate concentration at any location x, ML-3

- ci :

-

bulk liquid phase inlet substrate concentration, ML-3

- C:

-

dimensionless substrate concentration defined as clci

- Cx :

-

dimensionless substrate concentration defined as Cx/Ci

- Dc :

-

diffusivity of substrate in biofilm, L2r-1

- Dw :

-

molecular diffusivity of substrate in the liquid, L2T-1

- E :

-

mass transfer coefficient defined as Dw/e, LT-1

- e :

-

depth of stagnant liquid layer adjacent to biofilm,L

- F :

-

Mathematical expression to be_substituted in Eq. (31) to calculate the definite integral Z

- H :

-

depth of filter,L

- h :

-

liquid film thickness,L

- K :

-

dimensionless ratio of mass transfer rate to kinetic rates(see Eq. (B3))

- Ks :

-

Monod-half velocity coefficient, ML-3

- k}:

-

maximum utilization rate of rate limiting substrate, T-1

- k1 :

-

biological rate (equation) coefficient (see Eq. (4)), T-1

- k2 :

-

biological rate (equation) coefficient (see Eq. (4)), L-1

- k3 :

-

biological rate (equation) coefficient (see Eq. (4)), M-1 L3

- L :

-

wet microbial film thickness,L

- l :

-

dimensional filter length,L

- M}:

-

dimensionless biofilm thickness

- N :

-

flux of substrate, ML2}T'-1}

- Qa :

-

hydraulic loading rate, L3 L-2T-1

- q :

-

rate of flow per unit width, L3 T-1L-1

- Q:

-

volumetric rate of flow, L3 T'-1

- S:

-

specific surface area, L2 L-3}

- wav :

-

average velocity of liquid in z direction, LT-1

- Z:

-

dimensionless distance measured in flow direction from the origin

- Z:

-

value of the definite integral related to the filter length (see Eq. 31))

- z:

-

axial distance measured in flow direction from the origin,L

- α:

-

dimensionless filter depth

- X :

-

dimensionless distance measured normal to flow direction

- x :

-

dimensional distance measured normal to flow direction,L

- Xc :

-

microbial density within biofilm, ML{-3}}

- γ:

-

specific gravity,ML - 2 T - 2

- μ:

-

dynamic viscosity,ML - 1 T-1

- λ:

-

effectiveness coefficient

- π:

-

biological removal ratio (biological efficiency)

- πD :

-

k s h / Dw in whichk s is a proportionality constant inLT' -1

References

Atkinson, B., Daoud, I. S., and Williams, D. A. (1968),Trans. Inst. Chem. Engrs. 52, 248–259.

Atkinson, B. and Daoud, I. S. (1970),Trans. Inst. Chem. Engrs. 48, 245–254.

Atkinson, B. and Williams, D. A. (1971),Trans. Inst. Chem. Engrs. 49, 215–224.

Atkinson, B. and Davies, I. J. (1974),Trans. Inst. Chem. Engrs. 52, 248–259.

Atkinson, B. and How, S. Y. (1974),Trans. Inst. Chem. Engrs. 52, 260–268.

Atkinson, B. and Abdel Rahman Ali, M. E. (1976),Trans. Inst. Chem. Engrs. 54 239–250.

Muslu, Y. (1983),Water Res. 17(1), 105–115.

Muslu, Y. and Sansarci, H. (1983),Cevre 83 Sempozyumu, Dokuzeylul Univ. Muh. Mim. Fak., Bornova, Izmir, Turkey.

Muslu Y. (1984),J. Envir. Engrg., ASCE 110(5), 961–975.

Muslu Y. (1992),J. Biotechnol. 23, 183–191.

Muslu Y. (1990),Water, Air Soil Pollut. 53, 297–314.

Rittman, B. E. and McCarty, P. L. (1981),J. Envir. Engrg. Div. ASCE,107(EE4), 889–900.

Sansarci, H. (1980), Ph.D. thesis, 1st. Tech. Univ., Istanbul, Turkey.

Suidan, M. T. (1986),J. Envir. Engrg. ASCE 112(1), 78–93.

Suidan, M. T., Rittman, B. E. and Traegner, U. K. (1987),Water Res. 21(4), 491–498.

Williamson, K. and McCarty, P. L. (1976)J.Water Pol. Cont. Fed. 48(1), 9–24.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Muslu, Y. Use of numerical methods in the design of biofilm reactors. Appl Biochem Biotechnol 36, 119–136 (1992). https://doi.org/10.1007/BF02929692

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02929692