Abstract

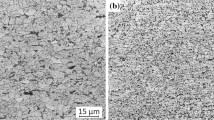

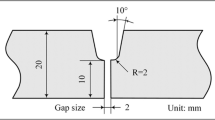

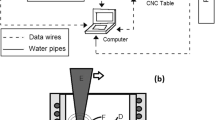

In this investigation, hybrid laser/arc welding (HLAW) was employed to join 8-mm-thick high-strength quenched and tempered steel (HSQTS) plates in the butt- and T-joint configurations. The influences of welding parameters, such as laser power, welding speed, stand-off distance (SD) between the arc of gas metal arc welding, and the laser heat source on the weld quality and mechanical properties of joints, were studied to obtain non-porous and crack-free fully-penetrated welds. The weld microstructure, cross-section, and mechanical properties were evaluated by an optical microscope, and microhardness and tensile tests. In addition, a finite element model was developed to investigate the thermal history and molten pool geometry of the HLAW process to join the HSQTS. The numerical study demonstrated that the SD had a paramount role in good synergy between the heat sources and the stability of the keyhole. For the butt-joint configuration, the results showed that, at a higher welding speed (35 mm/s) and optimum SD between the arc and laser, a fully-penetrated sound weld could be achieved. A non-porous weld in the T-joint configuration was obtained at a lower welding speed (10 mm/s). Microstructural evaluations indicated that the formation of residual austenite and the continuous network of martensitic structure along the grain boundary through the heat affected zone were the primary reasons of the softening behavior of this area. This was confirmed by the sharp hardness reduction and failure behavior of the tensile coupons in this area.

Similar content being viewed by others

References

Barenyi I, Hires O, Liptak P (2013) Changes in mechanical properties of armored UHSLA steel ARMOX 500 after over tempering. Probl Mechatron Armament Aviat Saf Eng 14:7–14

Magudeeswaran G (2008) Effect of welding consumables on tensile and impact properties of shielded metal arc welded high strength, quenched and tempered steel joints. J Iron Steel Res 15:87–94

Alkemade SJ (1996) The weld cracking susceptibility of high hardness armour steel. Australian defense science and technology organization: Aeronautical and Maritime Research Laboratory. file:///C:/Users/Mehdi/Downloads/10.1.1.555.2194(1).pdf

Magudeeswaran G, Balasubramaniarr V, Reddy GM et al (2008) Effect of welding processes and consumables on tensile and impact properties of high strength quenched and tempered steel joints. J Iron Steel Res 15(6):87–94

Katayama S, Abe Y, Mizutani M et al (2011) Deep penetration welding with high-power laser under vacuum. Trans JWRI 40(1):15–19

Zhang X, Ashida E, Tarasawa S et al (2011) Welding of thick stainless steel plates up to 50 mm with high brightness lasers. J Laser Appl 23(2):220–222

Mazar Atabaki M, Ma J, Yang G et al (2014) Hybrid laser/arc welding of advanced high strength steel in different butt-joint configurations. Mater Des 64:573–587

Mazar Atabaki M, Ma J, Liu W et al (2015) Pore formation and its mitigation during hybrid laser/arc welding of advanced high strength steel. Mater Des 67:509–521

Pan Q, Mizutani M, Kawahito Y et al (2016) High power disk laser-metal active gas arc hybrid welding of thick high tensile strength steel plates. J Laser Appl 28:120–124

Katayama S, Naito Y, Uchiumi S et al (2006) Physical phenomena and porosity prevention mechanism in laser-arc hybrid welding. Trans JWRI 35(1):13–18

Ming G, Zeng X, Hu Q (2007) Effects of gas shielding parameters on weld penetration of CO2 laser-TIG hybrid welding. J Mater Process Technol 184:177–183

Huang Y, Zhang YM (2010) Laser-enhanced GMA. Weld J 89:181–188

Mazar Atabaki M (2015) Study of issues in difficult-to-weld thick materials by hybrid laser arc welding. Dissertation, Southern Methodist University.

Zhou J, Tsai HL, Wang PC (2006) Transport phenomena and keyhole dynamics during pulsed laser welding. ASME J Heat Transf 128:680–690

Mazar Atabaki M, Nikodinovski M, Chenier P et al (2014) Experimental and numerical investigations of hybrid laser arc welding of aluminum alloys in the thick T-joint configuration. Opt Laser Technol 59:68–92

Norris JT, Perricone MJ, Roach RA et al (2007) Evaluation of weld porosity in laser beam seam welds: optimizing continuous wave and square wave modulated processes. SANDIA REPORT, U.S. Department of Energy, 1:1–27

Berger P, Hugel H, Graf T (2011) Understanding pore formation in laser beam welding. Phys Proced 12:241–247

Zhou J, Tsai HL (2008) Modeling of transport phenomena in hybrid laser-MIG keyhole welding. Int J Heat Mass Transf 51:4353–4366

Turichin G, Tsibulskiy I, Kuznetsov M et al (2015) Influence of the gap width on the geometry of the welded joint in hybrid laser-arc welding. Phys Proced 78:14–23

Hu Y, He X, Yu G et al (2012) Heat and mass transfer in laser dissimilar welding of stainless steel and nickel. Appl Surf Sci 258:5914–5922

Piekarska W, Kubiak M, Saternus Z (2010) Application of ABACUS to analysis of the temperature field in elements heated by moving heat sources. Achiev Foundry Eng 10(4):177–182

Liu W, Ma J, Mazar Atabaki M et al (2015) Joining of advanced high-strength steel to AA 6061 alloy by using Fe/Al structural transition joint. Mater Des 68:146–157

Campana G, Fortunato A, Ascari A et al (2007) The influence of arc transfer mode in hybrid laser-MIG welding. J Mater Process 191:111–113

Mazar Atabaki M, Yazdian N, Kovacevic R (2016) Partial penetration laser-based welding of aluminum alloy (AA 5083-H32). Optik Int J Light Electron Opt 127(16):6782–6804

Cao X, Wanjara P, Huang J et al (2011) Hybrid fiber laser-arc welding of thick section high strength low alloy steel. Mater Des 32:3399–3413

Nguyen TC, Weckman DC, Johnson DA et al (2006) High speed fusion weld bead defects. Sci Technol Weld Join 11:618–633

Bagger C, Flemmig O, Olsen O (2004) Review of laser hybrid welding. J Laser Appl 17(1):1–15

Frostevarg J, Kaplan AFH (2014) Undercuts in laser arc hybrid welding. Phys Proced 56:663–672

Mazar Atabaki M, Ma J, Liu W et al (2015) Hybrid laser/arc welding of advanced high strength steel to aluminum alloy by using structural transition insert. Mater Des 75:120–135

Kawahito Y, Mizutani M, Katayama S (2007) Elucidation of high-power fiber laser welding phenomena of stainless steel and effect of factors on weld geometry. J Phys D 40:5854–5859

Acknowledgements

The authors would like to thank Andrew Socha for his valuable help in the setup of the welding machines. This work was partially funded by NSF Grant IIP-1034652.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mazar Atabaki, M., Yazdian, N. & Kovacevic, R. Hybrid laser/arc welding of thick high-strength steel in different configurations. Adv. Manuf. 6, 176–188 (2018). https://doi.org/10.1007/s40436-017-0193-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-017-0193-6