Abstract

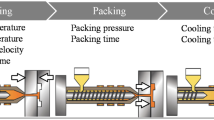

Plastic injection molding has been widely used in the past and is a dominant forming approach today. As the customer demands require materials with better engineering properties that were not feasible with polymers, powder injection molding with metal and ceramic powders has received considerable attention in recent decades. To better understand the differences in the plastic injection molding, metal injection molding, and ceramic injection molding, the effects of the core process parameters on the process performances has been studied using the state-of-the-art computer-aided engineering (CAE) design tool, PIMSolver® The design of experiments has been conducted using the Taguchi method to obtain the relative contributions of various process parameters onto the successful operations.

Similar content being viewed by others

References

Atre, S. V., S. J. Park, R. Zauner, and R. M. German, 2007, Process simulation of powder injection molding. i. identification of significant parameters during the mold filling phase, Powder Metallurgy 50(1), 76–85.

Chung, S. T., T. K. Kang, S. J. Park, Y. S. Kwon, H. K. Ahn, and T. S. Yoon, 2001, Integrated CAE analysis for powder injection moulding: filling, packing and cooling stages, 2001 ANTEC, Society of Plastics Engineers, Dallas, TX, 2001.

German, R.M. and A. Bose, 1997, Injection Molding of Metals and Ceramics, Metal Powder Industries Federation, Princeton, NJ.

German, R. M., 1993, Technological barriers and opportunities in powder injection molding, Powder Metallurgy International 25, 165–169.

German, R. M., 1990, Powder Injection Molding, Metal Powder Industries Federation, Princeton, NJ.

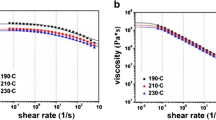

Hausnerová, B., 2010, Rheological characterization of powder injection molding compounds, Polimery/Polymers 55(1), 3–11.

Hausnerova, B., T. Sedlacek, P. Filip, and P. Saha, 2011, The effect of powder characteristics on pressure sensitivity of powder injection moulding compounds, Powder Technology 206(3), 209–213.

Kwon, T.H and S.Y. Ahn, 1995, Slip characterization of powderbinder mixtures and its significance in the filling process analysis of powder injection molding, Powder Technology 85, 45–55.

NIST/SEMATECH e-Handbook of Statistical Methods, http://www.itl.nist.gov/div898/handbook/, 2011.

Ross, P. J., 1988, Taguchi Techniques for Quality Engineering, McGraw-Hill Book Company.

Taguchi, G., 1987, System of Experimental Design, Dearborn, Michigan, and White Plains, New York: ASI Press and UNIPUB-Kraus International Publications, 1987.

Urval, R., 2004, “CAE-Based Process Design Of Powder Injection Molding For Thin-Walled Micro-Fluidic Device Components,” M.S. Thesis, Oregon State University, Corvallis, OR.

Urval, R., S. Lee, S.V. Atre, S.-J. Park, and R.M. German, 2008, Optimisation of process conditions in powder injection moulding of microsystem components using a robust design method: Part I. Primary design parameters, Powder Metallurgy 51(2), 133–142.

Urval, R., S. Lee, S.V. Atre, S.-J. Park, and R.M. German, 2010, Optimisation of process conditions in powder injection moulding of microsystem components using robust design method Part 2 — Secondary design parameters, Powder Metallurgy 53(1), 71–81.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, S.W., Ahn, S., Whang, C.J. et al. Effects of process parameters in plastic, metal, and ceramic injection molding processes. Korea-Aust. Rheol. J. 23, 127–138 (2011). https://doi.org/10.1007/s13367-011-0016-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13367-011-0016-4