Abstract

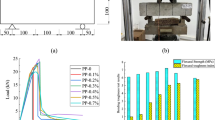

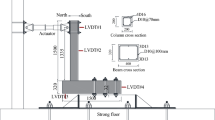

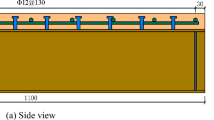

Fiber-optic sensors (FOS) are increasingly being used in reinforced-concrete (RC) structures for their accuracy and durability. One of the drawbacks of FOS is their fragility at installation. One recently developed method to address such deficiency is to install the FOS on a short bar (supplemental bar) that is rigidly connected to the structural reinforcement bars prior to concrete pouring. However, the durability of such systems under harsh environmental conditions has not been well established. In order to better understand the behavior of the aforementioned FOS systems under harsh environmental conditions, seven half-scale RC beams with glass fiber-reinforced polymer bars were exposed to four different exposure regimes, in the present study. After 14 months of exposure to harsh environmental conditions, the RC beams were subjected to static flexural testing to evaluate the FOS system behavior under each environmental condition. In addition, the strain responses of the sensors mounted on the supplemental bars and those in the main bars were monitored to validate the newly developed FOS mounting system. The results of this study show that the proposed FOS mounting system can efficiently capture the actual strain in all environmental conditions tested in this study except immersion exposure under high alkali solution. In addition, the flexural deformation and the exposure impact to the beam capacity were evaluated.

Similar content being viewed by others

References

ACI (2014) ACI 318-14 Building code requirements for structural concrete and commentary. ACI, Farmington Hills, MI

ACI440.1R (2015) Guide for the design and construction of structural concrete reinforced with fiber-reinforced polymer bars. American Concrete Institute, Farmington Hills

Al-Salloum Y, El-Gamal S, Almusallam T, Alsayed S, Aqel M (2013) Effect of harsh environmental conditions on the tensile properties of GFRP bars. Compos Part B Eng 45(1):835–844

Al-Sunna R, Pilakoutas K, Hajirasouliha I (2012) Deflection behavior of FRP reinforced concrete beams and slabs: an experimental investigation. Compos Part B Eng 43(5):2125–2134

Amidi S, Wang J (2016) Deterioration of the FRP-to-concrete interface subject to moisture ingress: effects of conditioning methods and silane treatment. Compos Struct 153:380–391

ASTM-C1018 (2003) ASTM International standard test method for flexural toughness and first-crack strength of fiber-reinforced concrete (using beam with third-point loading). American Society of Testing and Materials, Philadelphia

ASTM-C31 (2017) ASTM International standard practice for making and curing concrete test specimens in the field. American Society of Testing and Materials, West Conshohocken

ASTM-C39 (2017) ASTM International standard test method for compressive strength of cylindrical concrete specimens. American Society of Testing and Materials, West Conshohocken

ASTM-E1856 (2013) Standard guide for evaluating computerized data acquisition systems used to acquire data from universal testing machines. American Society of Testing and Materials, West Conshohocken

Bagchi A, Murison E, Mufti A, Noman A (2010) Evaluation of rugged fiber optic sensor system for monitoring reinforced concrete structure. Exp Tech 34:49–53

Bagchi A, Rivera E, Mufti A (2007) Evaluation of a rugged fiber optic sensor system for monitoring reinforced concrete structures, 3

Bank L, Moshe P, Katz A (1998) The effect of material degradation on bond properties of fiber reinforced bars in concrete. ACI Mater J 95:232–243

Bao J, Wang L (2017) Capillary inhibition of water in discrete planar cracks. Constr Build Mater 146(15):381–392

Benmokrane B, Tighiouart B, Chaallal O (1996) Bond strength and load distribution of composite GFRP reinforcing bars in concrete. ACI Mater J 93:246–252

Chen Y, Davalos JF, Ray I, Kim HY (2007) Accelerated aging tests for evaluation of durability performance of FRP reinforcing bars for concrete structures. J Compos Struct 78:101–111

CSA-806 (2017) Design and construction of building structures with fibre-reinforced polymers. Canadian Standard Association, Rexdale

CSA-A23.3 (2017) Design of concrete structures. Canadian Standard Association, Rexdale

D’Alessandro A, Ubertini F, Macias E, Triguero R, Downey A, Laflamme S (2017) Static and dynamic strain monitoring of reinforced concrete components through embedded carbon nanotube cement-based sensors. Shock Vib J 2017:11

Davalos JF, Chen Y, Ray I (2008) Effect of FRP bar degradation on interface bond with high strength concrete. Cem Concr Compos 30:722–730

Guemez A, Lopez A, Diaz Maroto P, Lozano A, Sierr Perez J (2018) Structural health monitoring in composite structures by fiber-optic sensors. Sens J 18(4):1094

He X, Dai L, Yang W (2017) Durability and degradation mechanism of GFRP bars embedded in concrete beams with cracks. Sens J 6(4):17–24

ISIS (2008) ISIS Canada design manual no. 4. FRP rehabilitation of reinforced concrete structures. The Canadian Network of Centers of Excellence on Intelligent Sensing for Innovative Structures, Winnipeg

JSCE (1984) Method of tests for flexural strength and flexural toughness of steel-fiber- reinforced concrete-SF4. Japan Society of Civil Engineers, Tokyo

Jungkuist DA (2000) Simulation of enviro-mechanical durability for life prediction of E-glass/vinyl ester composites using a bridge service environment. M.Sc. Thesis, Virginia Polytechnic Institute and State University

Krohn DA, MacDougall TW, Mendez A (2015) Fiber optic sensors: fundamentals and applications. SPIE Press Book, Washington

Lianrong C, Sidney M, Dudley RM (1994) Specimen geometry and toughness of steel-fiber-reinforced concrete. J Mater Civ Eng 6:529–541

Micelli F, Nanni A (2004) Durability of concrete structures. Constr Build Mater 18(7):491–503

Mikhailov SJ (2012) Fiber bragg grating sensors for harsh environments. Sens J 12(2):1898–1918

Mishra A, Choudhary D, Jain N, Kumar M, Zharda N, Dutt D (2008) Effect of concentration of alkaline liquid and curing time on strength and water absorption of geopolymer concrete. ARPN J Eng Appl Sci 3(1):14–18

Mohamed N, Farghaly A, Benmokrane B (2015) Aspects of deformability of concrete shear walls reinforced with glass fiber-reinforced bars. J Compos Constr 19:06014001

Mufti A, Banthia N, Benmokrane B, Boulfiza M, Newhook J (2007) Durability of GFRP composite rods. J Constr Int 29(2):37–42

Naidu AL, Jagadeesh V, Bahubalendruni MR (2017) A review on chemical and physical properties of natural fiber reinforced composites. Int J Adv Res Eng Technol 8(1):56–68

Nkuruziza G, Debaiky A, Cousin P, Benmokrane B (2005) Durability of GFRP bars: a critical review of the literature. Prog Struct Mater Eng 7:194–209

Pavel S, Kolarova I, Sehnal T, Masilko J, Opravil T (2016) The effect of material degradation on bond properties of fiber reinforced bars in concrete. In: International conference on ecology and new building materials and products, vol 151, pp 10–17

Pinet E (2009) Fabry–Pérot fiber-optic sensors for physical parameters measurement in challenging conditions. J Sens 2009:9

Robert M, Cousin P, Benmokrane B (2009) Durability of GFRP reinforcing bars embedded in moist concrete. J Compos Constr 13:66–73

Robert M, Wang P, Cousin P, Benmokrane B (2010) Temperature as accelerating factor for long-term durability of FRP’s: should be there limitations? ASCE J Compos Constr 14(4):361–367

Sim J, Moon D, Oh H, Park C (2005) Hybrid FRP rod for reinforcement and smart- monitoring in concrete structure. In: Proceedings of the international symposium on bond behavior of FRP in structures (BBFS2005), Hong Kong, pp 297–302

Subramaniam KV, Ghosn M, Ali-Ahmad M (2007) Impact of freeze-thaw degradation on FRP-concrete interface fracture. In: Grosse CU (ed) Advances in construction materials. Springer, Berlin, Heidelberg

Swit G (2000) Durability of stressed E glass fibre in alkaline medium. In: Recent developments in durability analysis of composite systems. A A Balkema Publishers

Torkan B (2010) Master’s thesis, Concordia University, Development of a protection mechanism for fiber optic sensors in monitoring GFRP reinforced concrete beams. Montreal, Canada

Won J, Park C (2006) Effect of environmental exposure on the mechanical and bonding properties of hybrid FRP reinforcing bars for concrete structures. J Compos Mater 40(12):1063–1076

Yoo D, Banthia N, Yoon Y (2016) Flexural behavior of ultra-high-performance fiber-reinforced concrete beams reinforced with GFRP and steel rebars. Eng Struct 111:246–262

Acknowledgements

The support of the Natural Sciences and Engineering Research Council (NSERC) of Canada is gratefully acknowledged. The authors also thank Pultrall Inc. for donating the FRP materials for this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rahmatian, A., Roy, T.B., Mofidi, A. et al. Long-term performance monitoring of GFRP-reinforced concrete beams using sensor-mounted supplemental rebars under harsh environmental conditions. J Civil Struct Health Monit 9, 293–306 (2019). https://doi.org/10.1007/s13349-019-00330-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13349-019-00330-1