Abstract

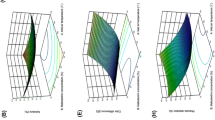

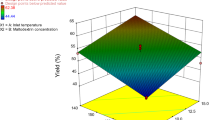

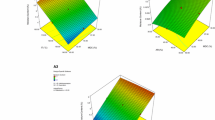

The aim of this study was to optimize the spray drying process for beetroot juice. Influence of feed flow rate (8, 10 and 11 mL/min), processing temperature (140, 150 and 160 °C) and maltodextrin concentration (20, 25, and 30%) on packed bulk density, moisture content and betalain content of beetroot powder were assessed using response surface methodology. The following optimum process parameters were determined; feed flow rate feed flow rate of 10 mL/min, processing temperature of 149 °C and maltodextrin concentration of 20%. The predicted values for packed bulk density, moisture content and betalain content were 0.62 g/mL, 6.12 and 33.84 mg/100 g of dry matter, respectively. Within the optimum parameters, the experimental values for packed bulk density, moisture content and betalain content were 0.62 ± 0.1 g/mL, 6.10 ± 0.1 and 33.14 ± 0.1 mg/100 gm of dry matter. The similarity of the experimental results to the predicted values verified the models.

Similar content being viewed by others

References

Cai Y, Corke H (1999) Amaranthus betacyanin pigments applied in model food system. J Food Sci 64(5):869–873

Cassano A, Conidi C, Timpone R, Avella M, Drioli E (2007) A membrane-based process for the clarification and the concentration of the cactus pear juice. J Food Eng 80:914–921

Fang Z, Bhandari B (2011) Effect of spray drying and storage on the stability of bayberry polyphenols. Food Chem 129:1139–1147

Fazaeli M, Emam-Djomeh Z, Ashtari AK, Omid M (2012) Effect of process conditions and carrier concentration for improving drying yield and other quality attributes of spray dried black mulberry (Morus nigra) juice. Int J Food Eng 8:1–20

Goula AM, Adamopoulos KG (2010) A new technique for spray drying orange juice concentrate. Innov Food Sci Emerg Technol 11:342–351

Hennigs C, Kockel TK, Langrish TA (2001) New measurements of the sticky behavior of skim milk powder. Dry Technol 19:471–484

Herbach KM, Stinzing FC, Carle R (2004) Impact of themal treatment on color and pigment pattern of red beet (Beta vulgaris L.) preparations. J Food Sci 69:C491–C498

Kha CT, Nguyen HM, Roach DP (2010) Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordicacochinchinensis) fruit aril powder. J Food Eng 98:385–392

Kim EHJ, Chen D, Pearce D (2009) Surface composition of industrial spray-dried milk powders. 2. Effects of spray drying conditions on the surface composition. J Food Eng 94(2):169–181

Kujala TS, Loponen JM, Klika KD, Pihlaja K (2000) Phenolics and betacyanins in red beetroot (Beta vulgaris) root: distribution and effect of cold storage on the content of total phenolics and three individual compounds. J Agric Food Chem 48:5338–5342

Kwapinska M, Zbicinski I (2005) Prediction of final product properties after co-current spray drying. Dry Technol 23:1653–1665

Mishra P, Mishra S, Mahanta CL (2014) Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amLa (Emblica officinalis) juice powder. Food Bioprod Process 92(3):252–258

Mishra P, Rai GK, Mahanta CL (2015) Process standardization food development of spray dried lemon juice powder and optimizationof amLa lemon based RTS (ready to serve) drink using response surface methodology. J Food Process Preserv 39:1216–1228

Mishra P, Brahma A, Seth D (2017) Physicochemical, functionality and storage stability of hog plum (Spondia pinnata) juice powder produced by spray drying. J Food Sci Technol. doi:10.1007/s13197-017-2531-x

Mridula D, Gupta RK, Bhadwal S, Khaira H, Tyagi SK (2016) Optimization of food materials for development of nutritious pasta utilizing groundnut meal and beetroot. J Food Sci Technol 53:1834

Ranganna S (1986) Handbook of analysis and quality control for fruits and vegetable products, 2nd edn. Tata McGraw Hill Publ Co., New Delhi

Ratanasiriwat P, Worawattanamateekul W, Klaypradit W (2013) Properties of encapsulated wasabi flavour and its application in canned food. Int J Food Sci Technol 48:749–757

Ravichandran K, Thaw Saw NMM, Mohdaly AAA, Gabr AMM, Kastell A, Riedel H, Cai Z, Knorr D, Smetanska I (2013) Impact of processing of red beet on betalain content and antioxidant activity. Food Res Int 50(2):670–675

Sagar VR, Suresh Kumar P (2010) Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Technol 47(1):15–26

Singh JP, Kaur A, Shevkani K, Singh N, Singh B (2016) Physicochemical characterisation of corn extrudates prepared with varying levels of beetroot (Beta vulgaris) at different extrusion temperatures. Int J Food Sci Technol 51:911–919

Solval KM, Sundarajan S, Alfaro L, Sathivel S (2012) Development of cantaloupe (Cucumismelo) juice powder using spray drying technology. LWT-Food Sci Technol 46:287–293

Tonon VR, Brabet C, Hubinger M (2008) Influence of process conditions on the physicochemical properties of acai powder produced by spray drying. J Food Eng 88:411–418

Tonon RV, Baroni AF, Brabet C, Gibert O, Pallet D, Hubinger MD (2009) Water sorption and glass transition temperature of spray dried acai (Euterpe oleracea Mart.) juice. J Food Eng 94:215–222

Vulic J, Canadanovic-Brunet J, Cetkovic G, Tumbas V, Djilas S, Cetojevic-Simin D, Canadanovic V (2012) Antioxidant and cell growth activities of beet root pomace extracts. J Funct Foods 4:670–678

Walton DE, Mumford CJ (2000) The morphology of spray dried particles a quantitative view. Dry Technol 18:1945–1986

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, B., Hathan, B.S. Process optimization of spray drying of beetroot Juice. J Food Sci Technol 54, 2241–2250 (2017). https://doi.org/10.1007/s13197-017-2659-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2659-8