Abstract

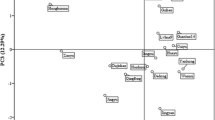

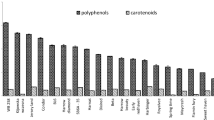

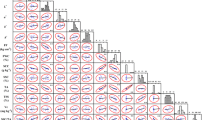

Characterization of physical properties of fruits represents the first vital step to ensure optimal performance of fruit processing operations and is also a prerequisite in the development of new processing equipment. In this study, physical properties of engineering significance to processing of three popular cultivars of clingstone peaches were evaluated, including dimensional parameters, mass, dimensional ratios, aspect ratio, elongation index, sphericity, bulk density, texture, color, and flavor. Based on these physical properties, multivariate analysis of variance (MANOVA), canonical variate analysis (CVA), principal component analysis (PCA), and partial least squares and linear discriminate analysis (PLS-LDA) were applied to qualitatively and quantitatively discriminate the cultivar difference. Results showed that the studied peach cultivars had significantly different (p < 0.05) geometric characteristics. The peaches can be classified based on the cheek diameter (Dc) into three different size categories, including small- (Dc less than 60 mm), medium- (Dc between 60 mm and 70 mm), and large- (Dc higher than 70 mm) sized peaches. The peach flesh firmness significantly (p < 0.05) decreased with the increase of peach size, while the pit dimensions were independent of peach size. There were no apparent distinctions in color characteristics, bulk density, and sugar content among the three cultivars. The measurements and quantitative discrimination of peach properties in this study would benefit equipment design and process innovation to enhance the processing efficiency and quality of processed peaches.

Similar content being viewed by others

References

Abbott, J. A., & Lu, R. (1996). Anisotropic mechanical properties of apples. Transactions of the ASAE, 39(4), 1451–1459.

Bayram, M. (2005). Determination of the sphericity of granular food materials. Journal of Food Engineering, 68(3), 385–390.

Berrueta, L. A., Alonso-Salces, R. M., & Héberger, K. (2007). Supervised pattern recognition in food analysis. Journal of Chromatography A, 1158(1), 196–214.

Bruhn, C. M., Feldman, N., Garlitz, C., Harwood, J., Ivans, E., Marshall, M., et al. (1991). Consumer perceptions of quality: apricots, cantaloupes, peaches, pears, strawberries, and tomatoes. Journal of Food Quality, 14(3), 187–195.

California Cling Peach Board (2009) Cling peach commodity fact. California Foundation for Agriculture in the Classroom (CFAITC). Available at: http://www.cfaitc.org/factsheets/pdf/ClingPeaches.pdf. Accessed 27 August 2013.

Cantín, C. M., Gogorcena, Y., & Moreno, M. (2010). Phenotypic diversity and relationships of fruit quality traits in peach and nectarine [Prunus persica (L.) Batsch] breeding progenies. Euphytica, 171(2), 211–226.

Crisosto, C., Day, K., Crisosto, G., & Garner, D. (2001). Quality attributes of white flesh peaches and nectarines grown under California conditions. Journal of American Pomological Society, 55, 45–51.

Crisosto, C., Valero, C., & Slaughter, D. (2007). Predicting pitting damage during processing in Californian clingstone peaches using color and firmness measurements. Applied Engineering in Agriculture, 23(2), 189–194.

Delwiche, M., & Drews, E. (1992). Sensor mechanisms for improved peach pitting. Transactions of the ASABE, 35(3), 903–908.

Delwiche, M., Tang, S., & Mehlschau, J. (1989). An impact force response fruit firmness sorter. Transaction of ASABE, 32(1), 321–326.

Fideghelli, C., Della Strada, G., Grassi, F., & Morico, G. (1998). The peach industry in the world: present situation and trend. IV International Peach Symposium, 465, 29–40.

Génard, M., & Bruchou, C. (1992). Multivariate analysis of within-tree factors accounting for the variation of peach fruit quality. Scientia Horticulturae, 52(1–2), 37–51.

Génard, M., Souty, M., Holmes, S., Reich, M., & Breuils, L. (1994). Correlations among quality parameters of peach fruit. Journal of the Science of Food and Agriculture, 66(2), 241–245.

Infante, R., Martínez Gómez, P., Predieri, S., & PUBL, W. (2008). Quality oriented fruit breeding: peach [Prunus persica (L.) Batsch]. Journal of Food Agriculture & Environment, 6(2), 342–356.

Li, X., Li, F., & Han, D. (2006). Analysis of five-direction imaging and rotation installation for detection of orange quality. Transactions of the Chinese Society of Agricultural Machinery, 36(1), 94–100.

Li, X., Pan, Z., Upadhyaya, S. K., Atungulu, G. G., & Delwiche, M. (2011). Three-dimensional geometric modeling of processing tomatoes. Transactions of the ASABE, 54(6), 2287–2296.

Li, X., Zhang, A., Atungulu, G. G., Delwiche, M., Milczarek, R., Wood, D., et al. (2014). Effects of infrared radiation heating on peeling performance and quality attributes of clingstone peaches. LWT--Food Science and Technology, 55(1), 34–42.

Martínez-García, P. J., Fresnedo-Ramírez, J., Parfitt, D. E., Gradziel, T. M., & Crisosto, C. H. (2013). Effect prediction of identified SNPs linked to fruit quality and chilling injury in peach [Prunus persica (L.) Batsch]. Plant Molecular Biology, 81(1–2), 161–174.

Nalbandi, H., Seiiedlou, S., Hajilou, J., Moghaddam, M., & Adlipour, M. (2011). Physical properties and color characteristics of Iranian genotypes of cornelian cherry. Journal of Food Process Engineering, 34(3), 792–803.

Pan, Z., Li, X., Bingol, G., McHugh, T. H., & Atungulu, G. (2009). Development of infrared radiation heating method for sustainable tomato peeling. Applied Engineering in Agriculture, 25(6), 935–941.

Park, T. A., & Florkowski, W. J. (2003). Selection of peach varieties and the role of quality attributes. Journal of Agricultural and Resource Economics, 138–151.

Perez, A. & Pollack, S. (2002). Fruit and tree nuts outlook. Economic Research Service, United States Department of Agriculture, Washington, DC Report FTS-296. Available at http://www.ersusda.gov/publications/fts/jan02/fts296.pdf. Assessed 18 April 2013.

Pollack, S. & Perez, A. (2008). Fruit and tree nuts situation and outlook yearbook 2008. Washington DC: US Department of Agriculture.

Predieri, S., Ragazzini, P., & Rondelli, R. (2006). Sensory evaluation and peach fruit quality. Acta Hort, 713, 429–434.

Quilot, B., Kervella, J., & Génard, M. (2004). Shape, mass and dry matter content of peaches of varieties with different domestication levels. Scientia Horticulturae, 99(3–4), 387–393.

Rakotomalala, R. (2005). TANAGRA: a free software for research and academic purposes. In proceedings of EGC, 2, 697–702.

Rigney, M., Brusewitz, G., & Stone, M. (1996). Peach physical characteristics for orientation. Transactions of the ASABE, 39(4), 1493–1497.

Sahin, S. & Sumnu, S. (2006). Physical properties of foods. New York, NY: Springer.

Schnabel, G., & Crisosto, C. H. (2008). Seasonal applications of a pyraclostrobin and boscalid mixture do not impact same-year peach fruit quality attributes. HortTechnology, 18(4), 678–684.

Slaughter, D., Crisosto, C., Hasey, J., & Thompson, J. (2006). Comparison of instrumental and manual inspection of clingstone peaches. Applied Engineering in Agriculture, 22(6), 883–889.

U.S. Department of Agriculture (2012). Noncitrus fruits and nuts. In. USDA, National Agricultural Statistics Service (NASS) database, Washington DC, USA. Available at http://usda01.library.cornell.edu/usda/current/NoncFruiNu/NoncFruiNu-01–25–2013.pdf. Accessed 27 August, 2013.

Wang, J., Teng, B., & Yu, Y. (2006). The firmness detection by excitation dynamic characteristics for peach. Food Control, 17(5), 353–358.

Whitelock, D. P., Brusewitz, G. H., & Stone, M. L. (2006). Apple shape and rolling orientation. Applied Engineering in Agriculture, 22(1), 87.

Zhang, H., Chang, M., Wang, J., & Ye, S. (2008). Evaluation of peach quality indices using an electronic nose by MLR, QPST and BP network. Sensors and Actuators B: Chemical, 134(1), 332–338.

Acknowledgments

This research work was funded by the USDA-ARS Cooperative Research and Development Agreement (CRADA) project. The authors gratefully acknowledge Rebecca Milczarek from the USDA-ARS and Moy Michelle, James Valenti-Jordan, and Amy Schauwecker from the Del Monte Food Incorporation for their support in this study.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, X., Zhang, A., Atungulu, G. et al. Characterization and Multivariate Analysis of Physical Properties of Processing Peaches. Food Bioprocess Technol 7, 1756–1766 (2014). https://doi.org/10.1007/s11947-014-1269-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-014-1269-y