Abstract

Forest-derived biomaterials can play an integral role in a sustainable and renewable future. Research across a range of disciplines is required to develop the knowledge necessary to overcome the challenges of incorporating more renewable forest resources in materials, chemicals, and fuels. We focus on wood specifically because in our view, better characterization of wood as a raw material and as a feedstock will lead to its increased utilization. We first give an overview of wood structure and chemical composition and then highlight current topics in forest products research, including (1) industrial chemicals, biofuels, and energy from woody materials; (2) wood-based activated carbon and carbon nanostructures; (3) development of improved wood protection treatments; (4) massive timber construction; (5) wood as a bioinspiring material; and (6) atomic simulations of wood polymers. We conclude with a discussion of the sustainability of wood as a renewable forest resource.

Similar content being viewed by others

Wood’s 390 Millionth Birthday

Wood is one of the major innovations of land plants “invented” some 390 million years ago. Wood enabled individual plants to increase their stature and persistence in the environment, facilitating the ability of trees to play roles in landscape change and biome composition and to fundamentally alter the global cycling of water, minerals, and carbon. Since prehistoric times, humans have found wood invaluable for meeting many of their needs, including energy, tools, and shelter—not surprising given its near-ubiquity, versatility, and renewability. Only in the comparatively recent past have other nonrenewable natural resources, such as fossil fuels or metal ores, become the resources of choice to meet our material needs. We postulate that wood will play an increasing role in the sustainability of our future materials through both expansion of uses for current forest products and development of alternatives to materials currently derived from nonrenewable resources. Life cycle assessments, which categorize energy consumption and emission profiles for products over their whole life cycle,1,2 consistently show that many wood-based materials use less fossil fuels to produce than do competing materials.3,4 Using wood products can also lower atmospheric carbon dioxide levels because growing forests capture carbon and harvested wood products store the accumulated carbon while in service.

Historically, wood research has been the purview of wood technologists; however, we see the future of wood research as interdisciplinary, collaborative, quantitative, and meaningful, both scientifically and societally. In this review, we briefly introduce wood as a material, present current trends in forest products research advancing and expanding the role of wood-based materials in our sustainable materials future, and further discuss the sustainability of forests for wood resources. One notable exception from this review is cellulose nanomaterials research. Nevertheless, cellulose nanomaterials is the subject of another review in this JOM special edition.5

Wood Structure and Composition

Wood is an anisotropic cellular tissue, the structure and properties of which are derived to solve plant problems—sap conduction, mechanical support, and storage and synthesis of biochemicals—in space and over time.6,7 The properties of wood that make it desirable as a natural resource, such as its exceptional strength-to-weight ratio or the richness, breadth, and subtlety of cell wall biopolymers, are thus predicated on the biological origins and functions of wood in the living plant.

Wood solves the simultaneous need for conduction, support, and storage by combining arrays of cells of different sizes, shapes, chemistries, and functions, and it does so using large numbers of cells integrated over long distances (from root to branch). The bulk of wood is made of cells of an axial system oriented parallel to the long axis of the major tree components, including roots, trunks, and branches. The axial system is primarily implicated in conduction and mechanical support in most woods, with a lesser role in storage and synthesis. The other cell system in wood is the radial system, which is composed of cells oriented perpendicular to both the long axis of the tree component and growth rings. The radial system is primarily implicated in (connected to) storage and synthesis.

The two basic body plans for wood are that of softwoods (such as pines, cedars, and spruces; Fig. 1a) and that of hardwoods (such as elms, oaks, ashes, maples, and birches; Fig. 1b). Both softwoods and hardwoods share a fundamental anatomy based on relative relationships among the axial system, the radial system, and the typically round cross sections of roots, trunks, and branches. This topology gives rise to three distinct planes of view in wood: transverse, radial, and tangential (Fig. 1b). The transverse plane is the cross section that is perpendicular to the axial system. Radial and tangential planes are cut parallel to the axial system and oriented relative to the cells of radial system, parallel to the rays for a radial-longitudinal plane and perpendicular to the rays for a tangential-longitudinal plane.

From tree to cell wall layers. Stylized tree silhouettes for a generic softwood (a) and a generic hardwood (b). Variations in cell types, size, and distribution within the axial system gives rise to growth rings, which are used to define the three primary planes of wood structure (c). Photomicrographs of transverse sections of a typical softwood (d) and a typical hardwood (e). The idealized lamellar structure of cells with secondary walls (f) from the lumen outward, secondary cell wall layers (S3, S2, and S1), primary cell wall, and middle lamella

The primary differences between softwoods and hardwoods are found in the cells of the axial system (Fig. 1d and e, respectively)—the radial systems of each are, although different in their specific anatomy, generally similar in cell type, function, and distribution. Cells in wood, especially in dry wood, have two domains: the cell wall (the physical substance of the cell) and the cell lumen (interior void volume or air space delimited by the cell wall). Softwoods are characterized by a comparatively simple wood structure—greater than 90% of softwoods by volume are typically a single type of cell, the tracheid. Tracheids are long, thin cells serving double duty of conduction and mechanical support. Although the softwood-type body plan first evolved more than 390 million years ago, it continues to be an efficient, competitive design, boasting some of the tallest (Sequoia sempervirens, greater than 115 m tall) and oldest (Pinus longaeva, more than 4000 years old) living trees in the world. Hardwoods are characterized by a cellular-level division of labor between dedicated conductive cells (vessel elements) and mechanical cells (fibers). A third cell type, specialized for storage and synthesis, is also found in most hardwoods, axial parenchyma. The total volume of each cell type in hardwoods varies widely from species to species, and because hardwood species are found in most habitats that include woody plants, this diversity of patterns is the basis of the wide variety of wood structure and properties found in nature.

Most woody cells have secondary cell walls. Proceeding from the lumen of the cell outward, the first layer encountered is the innermost layer of the secondary cell wall, the thin S3. This is followed by the thick S2, the thin S1, the primary cell wall, and then the middle lamella. Secondary cell walls are nano-fiber-reinforced composites of highly oriented semicrystalline cellulose microfibrils embedded in a matrix of amorphous cellulose, hemicelluloses, and lignin. Elucidating the fine details of the cell wall nanostructure is still an open area of research.8,9 The S2 layer is much thicker than the S1 and S3 layers and therefore has a larger influence on wood properties than have the other cell wall layers. The helical angle the cellulose microfibrils make with the longitudinal cell axis is called the microfibril angle (Fig. 1f) and in the S3 layer is typically >70°, in the S2 is typically low (5°–30°), and is typically 50°–70° in the S1.6 The primary wall is very thin and characterized by a randomly oriented web of cellulose microfibrils.10,11 The middle lamella fills in the regions between cells (Fig. 1f) and consists of about 20% hemicelluloses embedded as an irregular, interconnecting network in a matrix of lignin.6,12 In most cases, the primary cell wall, middle lamella, and primary cell wall of the adjacent cell wall are not separable as distinct layers; these three layers together are known as the compound middle lamella. In typical wood cells, cellulose microfibrils are about 15–20 nm in diameter.10,13

Chemically, on a dry basis, secondary wood cell walls consist of about 35% highly oriented, semicrystalline cellulose microfibrils embedded in a matrix of amorphous cellulose (20%), hemicelluloses (30%), and lignin (15%).14 Cellulose, which is the most abundant biopolymer on Earth, is a linear polysaccharide made from the simple sugar d-glucose (Fig. 2a). Individual cellulose chains are held together by intermolecular and intramolecular hydrogen bonds to form the semicrystalline cellulose elementary fibrils. The structure of cellulose microfibrils in any cell wall layer is proposed to consist of a 3 by 4 array of approximately 3-nm-diameter semicrystalline cellulose elementary fibrils with thin layers of less-ordered structures integrated into the cellulose microfibrils between the elementary fibrils.10,11 Hemicelluloses are amorphous, highly branched polymers composed primarily of the sugars d-mannose (Fig. 2b), d-galactose, d-xylose (Fig. 2c), l-arabinose, and d-glucuronic acid. Lignin, which is the second most abundant biopolymer on Earth, is an amorphous, highly cross-linked aromatic polymer polymerized through free radical reactions from sinapyl alcohol (Fig. 2d), coniferyl alcohol, and p-cumaryl alcohol. Carbon–carbon (C–C) and carbon–oxygen–carbon (C–O–C; ether) bonds are formed during lignin polymerization. The overall chemical composition in wood can vary between tree species and type of wood tissue within a given tree.

Water is another important component of wood that affects numerous wood properties, including mechanical, thermal, electrical, dimensional stability, and durability.15 For example, changes in the amount of water in wood can cause changes of nearly 10 orders of magnitude in electrical properties and anisotropic dimensional changes in bulk wood of approximately 10, 5, and 0.1% in the tangential, radial, and longitudinal directions, respectively. The accessible hydroxyl (–OH) and other polar chemical groups (such as ether and carbonyl linkages) in the amorphous cellulose, hemicelluloses, and lignin readily adsorb water. The moisture content (MC) of wood is defined as water mass divided by oven-dried wood mass and when not in contact with liquid water depends on ambient temperature and relative humidity (RH). Below the fiber saturation point, approximately 30% to 40% MC, all water in wood is bound by intermolecular attractions within the wood cell wall polymers. At higher MCs, free water forms in wood cavities, such as cell lumina and open cell corners.

Current Topics

Industrial Chemicals, Biofuels, and Energy from Woody Materials

Energy-rich biopolymers that constitute woody cell walls present an important opportunity for production of renewable fuels and chemicals. Strategies for production of liquid fuels and chemicals from woody feedstocks can be generally divided into two classes consisting of biochemical pathways and thermochemical pathways. Biochemical pathways typically aim to depolymerize cellulose and hemicelluloses into C6 and C5 sugars (for example, Fig. 2a–c) using cocktails of hydrolytic enzymes. The process of hydrolyzing polysaccharides to soluble sugars is called “saccharification.” Challenges associated with enzymatic deconstruction of biomass are contributed by the complex lignocellulosic structure of wood cell walls.16 In lignocellulosic biofuels research, resistance to saccharification is often termed “recalcitrance.” Treatments that expose the biomass to elevated temperatures and chemicals such as dilute sulfuric acid,17 mixtures of organic solvents (such as methyl isobutyl ketone, ethanol, and water), which is also called organosolv,18 and sulfite19 have been shown to overcome recalcitrance and enhance saccharification yields of the resulting residues by increasing the accessibility of cellulose to enzymes. The solubilized sugar stream produced from enzymatic hydrolysis, called hydrolysate, is then subjected to additional biological or chemical catalytic upgrading to produce desired fuel molecules. The traditional process used for this purpose is biological fermentation to produce ethanol.20 More recent efforts aim to produce fuel molecules other than ethanol from hydrolysate by strategies wherein sugar-derived compounds such as furans, organic acids, and polyols serve as intermediates for the production of hydrocarbons through reduction and carbon–carbon coupling reactions.21,22

Thermochemical conversion pathways differ from biochemical conversion pathways in that they rely primarily on elevated temperatures, rather than on biocatalysts, to deconstruct biomass into small molecules. Technologies such as fast pyrolysis, gasification, and hydrothermal liquefaction fall under this category. Fast pyrolysis is a process wherein biomass is rapidly heated to temperatures of 400°C to 600°C in an inert environment where the feedstock decomposes into light gases including CO, CO2, and small hydrocarbons; condensable gasses comprising heavier hydrocarbons and aromatic compounds; and char. For liquid fuel production, the desired product is obtained by condensation of the heavy gasses into a liquid called “pyrolysis oil” or “bio-oil.” The competing reactions that occur during pyrolysis govern the formation of light gasses, condensable vapors, and char. These reactions occur at different rates and with different activation energies and thereby provide an opportunity to tune the product distribution by controlling process conditions. For example, production of condensable vapors occurs with a lower activation energy and by more rapid kinetics relative to char formation; therefore, very rapid heating in tandem with short residence times in the reactor shift product yields toward condensable gases while minimizing char formation.23 Raw bio-oil from pyrolysis has high oxygen content and therefore relatively low energy content compared with petroleum-derived liquid fuels. Efforts to address this challenge have resulted in processes such as catalytic fast pyrolysis,24 where raw pyrolysis vapors are passed through a deoxygenation catalyst prior to condensation, and fast hydropyrolysis where pyrolysis is performed under a significant overpressure of hydrogen gas, which removes oxygen from the biomass primarily in the form of H2O.25 Fast pyrolysis also serves as the first step in gasification, another thermochemical conversion strategy that produces syngas (i.e., a mixture of H2, CO, and CO2) from biomass by controlled reaction of the gaseous products with steam and/or oxygen at a high temperature (700°C to 1000°C). Although gasification plants for both coal and biomass have existed for several decades,26 this technology has experienced a resurgence of attention from the biofuels community due in part to recent projections that gasification technology could contribute significantly to future renewable heat and power generation.27

Although the importance of producing renewable fuels from woody feedstocks is widely recognized, recent techno-economic evaluations of biorefinery processes have highlighted the importance of producing additional valuable chemical co-products from wood polymers in order for biorefineries to achieve economic self-sustainability. For example, in the context of a biochemical biorefinery, the importance of lignin valorization has been specifically identified.28 Conventional biorefinery models combust lignin to generate process heat; however, recent advances in biochemical processing of lignin have resulted in genetically engineered microbes capable of metabolizing lignin into valuable platform chemicals.29 Alternative approaches have developed one-pot catalytic systems for depolymerization and subsequent conversion of lignin from poplar wood into high-value specialty chemicals, such as methoxypropylphenols, with high yield and selectivity.30 Such strategies are prompting researchers to re-envision the modern biorefinery to a process where biomass fractionation and conversion of lignin to valuable chemical co-products play a central role.31

Wood-Based Activated Carbon and Carbon Nanostructures

The earliest known use of wood-based carbon materials is 3750 BC when the ancient Egyptians and Sumerians used wood chars for the reduction of copper, zinc, and tin ores in the manufacture of bronze and as domestic smokeless fuel.32 Since then, many other forms of wood-based carbon materials have been developed, including activated carbons and carbon nanostructures.

Activated carbons are used in numerous commercial applications including water treatment, CO2 capture, energy storage, supercapacitors, and heterogeneous catalysis.33 They are also used in the food industry for purification of oils and fats and alcohol drinks, as well as in the chemical and pharmaceutical industries for gas and drug purification. The basic procedure to produce activated carbon is to first carbonize the material at high temperatures under inert environments to produce a microporous carbonaceous mass with a high surface-to-volume ratio. The surfaces in the microporous carbon can then be further activated by processes, such as steam activation, to increase the amount and specificity of its absorptivity. Although activated carbons can be produced from almost any carbon-based raw material, it is more cost effective and environmentally desirable to produce them from sustainable or waste materials. Activated carbons produced from wood or similar lignocellulosic materials show great promise because they can possess highly developed microporous structures that are likely enhanced by naturally occurring nanostructures in the cell walls. For example, activated carbons produced from coconut shells have long been shown to have high volumes of micropores, making them a commonly used raw material for applications where high adsorption capacity is needed, such as water filters. Nevertheless, the natural variability in precursors like wood poses challenges because it can result in production of activated carbons without the necessary control over important properties, which include porosity, morphology, mechanical properties, and surface chemistry.34 Fortunately, development of more flexible and robust routes to new carbon materials derived from renewable resources like wood is becoming a topic of increased interest and improvements are expected.33

Carbon nanofibers (CNFs) and carbon nanotubes (CNTs) are examples of carbon nanostructures that can be derived from wood. Based on the fact that isolated lignin has the largest carbon content among wood components, CNFs have been produced from lignins and used in fabrication of electrodes for lithium-ion batteries and supercapacitors.35 CNF networks can be produced by a process involving the rapid freezing of an aqueous lignin solution, followed by sublimation of the resultant ice, to form a uniform network made up of individual interconnected lignin nanofibers. Carbonization of lignin nanofibers yields a similarly structured CNF network.36 Researchers are also investigating first spinning lignin-based fibers followed by carbonization to create single CNFs.37 Lignin-based CNFs seem to be promising and may play a role in the lignin valorization needed to achieve economic self-sustainability in biorefineries.

CNTs are a particular form of fullerene, first reported by Iijima.38 They are tubular structures that can be 1–2 nm in diameter and ≥1 mm in length. CNTs have great tensile strength and are considered to be 100 times stronger than steel, while being only one sixth of its weight, making them potentially the strongest, smallest fiber known. They also exhibit high electrical conductivity, high surface area, unique electronic properties, and potentially high molecular adsorption capacity.39 Applications currently being investigated include polymer composites (conductive and structural filler), electromagnetic shielding, electron field emitters (flat panel displays), supercapacitors, batteries, hydrogen storage, and structural composites. Interestingly, CNTs have been produced from wood fiber using a low-temperature process, which included continuous oxidization at 240°C and cyclic oxidation at 400°C. The inside diameter of the CNTs was approximately 4–5 nm, and the outside diameter ranged from 10 nm to 20 nm. No CNTs were produced when pure lignin or pure cellulose were tested, indicating that the cell wall nanostructure, likely the cellulose elementary fibrils, plays an important role in CNT formation. Apparently, the differential ablation properties of the major cell wall components, cellulose, hemicellulose, and lignin, are critical for the formation of CNTs at comparatively low temperatures.40

Massive Timber Construction (Tall Wood Building)

Wood has been used as a building material for millennia. In the United States, most single-family homes are built using “stick frame” wood construction with wooden studs carrying the vertical loads and wood panel products, such as plywood or orientated strandboard (OSB), attached to the outside for lateral and transverse loads. Interest has recently increased in building nonresidential and multistory residential wood buildings using larger timber components. For example, in 2008, a nine-story high-rise was completed in London using wood structural members. The structure, called “24 Murray Grove,” became the world’s tallest residential wood structure.41 Timber buildings from 9 to 20 stories high are also planned in New York, Portland, Canada, Norway, and Austria.42

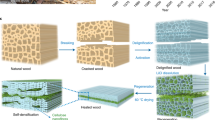

Tall wood buildings can be realized through the use of mass timber construction. “Mass timber” is a class of wood composites that includes glue-laminated timber (glulam), structural composite lumber, and cross-laminated timber (CLT) (Fig. 3). Glulam consists of stacked lumber glued along the grain to form a massive beam. Structural composite lumber is a general term that can refer to wood composites made from veneers or flakes of wood aligned so that the grain is parallel to form a billet. Structural composite lumber made from veneers is referred to as laminated veneer lumber (LVL). Structural composite lumber made from flakes is referred to as parallel strand lumber (PSL), laminated strand lumber (LSL), or orientated strand lumber (OSL), depending on the size and aspect ratio of the flakes used to make the composite. CLT has attracted the most attention for its use in tall wood buildings. CLT is a massive panel product made from layers of dimensional lumber where the long axis of each layer is orientated 90° from the previous layer. CLT panels may vary from approximately 50 mm to 500 mm in thickness, can be manufactured up to 18 m long, and are typically delivered to the job site with all openings for windows and doors precut.43 CLT is the main component of the 24 Murray Grove building and figures prominently in the design of the winners of the United States Tall Wood Building Prize competition.

Mass timber composites were developed throughout the 20th century; however, recent advances in manufacturing and fastening systems have made them easier to use and more attractive as a building material. The rise of large computer numerically controlled (CNC) routers now allows for massive CLT panels to be prefabricated to a high precision at the mill before being delivered to the jobsite. Massive timber composites are also being made under tighter control of RH, which is important because wood changes dimension with changes in MC.15 Furthermore, the dimensional stability of structural composite lumber and CLT are inherently greater than that of solid wood as a result of the different orientations of individual wood components within the larger timber.44 The dimensional stability of these composites is extremely important in high-rise construction where small, moisture-induced deformations are additive through the height of the building. Finally, new fastening systems such as self-tapping screws and epoxied steel rods have been developed to connect mass timber composites. These technologies have improved the moment-resisting capacity and seismic performance of timber joints.45 – 47

Developing Improved Wood Protection Treatments

Wood is widely used in construction in North America, and replacing decayed or moldy wood costs billions of dollars per year.48 In addition, concerns about decay sometimes prevent wood from being used. Clearly, improved decay resistance without significant added cost or detrimental environmental effects would increase wood utilization.

In wood construction, the primary agents of wood decay are brown rot fungi, which are adapted to this recalcitrant food source and produce a severe loss of wood strength during early decay. Whereas fungi and their secreted enzymes fit easily into the lumina of wood cells (Fig. 1f), the pores in the nanostructure of wood cell walls are too small for even the smallest enzymes to gain access. Brown rot fungi are able to attack wood by producing low-molecular-weight oxidants or oxidant precursors, much smaller than enzymes, which diffuse through the wood cell wall, to oxidize and cleave cell wall polymers. This releases soluble sugars that can be taken up as a carbon source by the fungus.49

If wood is wet enough to support microbial activity for a prolonged period, or cyclically wet and dry often enough, decay will occur unless the wood is treated with wood preservatives or chemically modified because the spores of wood decay organisms are ubiquitous. Wood preservatives are chemicals added to the wood to protect it from fungi and insect attack and frequently contain copper.50 Wood preservatives are registered pesticides, and future regulation and their availability depend on maintaining their registration with environmental regulators, such as the Environmental Protection Agency in the United States.51 An alternative to wood preservatives is a chemical or thermal modification of wood polymers to alter the wood chemical or physical structure to inhibit decay. Such modified wood products have significant market penetration in Europe and are commercially available worldwide. Commercialized techniques include thermal modification, impregnation and in situ polymerization of furfuryl alcohol, and acetylation by impregnation and reaction with acetic anhydride.

Current questions include how chemical modifications inhibit decay and how lower cost-effective modification procedures can be developed. The mechanism of decay prevention in acetylated wood has been the most extensively studied of all chemical modifications, but it is still debated.52 Acetylation becomes effective at approximately 10% to 20% weight gain by replacing wood polymer hydroxyl (–OH) groups (see Fig. 2) with acetoxy (–OCOCH3) groups.53 Wood polymers swell with moisture, increasing their free volume. In acetylated wood, the new acetoxy groups occupy some of this volume and make the wood polymers less hydrophilic, thereby lowering the amount of water that can be absorbed in wood cell walls. Among other theories, decay inhibition has been attributed to this lowered cell wall MC, which may result in lower diffusion rates for fungal oxidants through wood cell walls.52 Nevertheless, the connection between MC and diffusion inside the cell wall remains unclear.

It was recently proposed that ion diffusion inside wood is a percolation-controlled phenomenon,54 and recent experimental results showed a MC threshold below which ions did not diffuse through wood cell walls.55,56 This led to the hypothesis that the key to stopping fungal oxidant diffusion lies in preventing the formation of a percolating network of diffusion domains within the cell wall.57 This hypothesis, although unproven, suggests that it might be possible to develop new, low-cost modifications that inhibit decay by modifying only those cell wall polymers implicated in cell wall diffusion.

Wood as a Bioinspiring Material

In a living tree, wood is a multifunctional material simultaneously fulfilling the tree’s needs for sap conduction, mechanical support, and storage and synthesis of biochemicals. As with many of Nature’s materials, the performance of wood in a living tree is unrivaled by current synthetic materials and the study of Nature’s design secrets continues to be a reliable source to improve or develop new technologies. Researchers continue striving to understand the structure and properties of wood for inspiration to improve or create new materials, structural designs, and theoretical formulations.

As a complex composite, wood is providing academic inspiration for development of modeling and computational frameworks to solve optimization problems related to mechanical properties of complex heterogeneous materials.58 Branch-trunk joints in trees are complex orthotropic, fiber-reinforced composites with extraordinary strength and toughness. Biomimetic joints are being developed as an alternative approach to solve T-joint problems for potential use in lightweight aircraft structures.59 Renewable packaging films inspired by the nanostructure of wood cell walls have been formed by mixing cross-linked galactoglucomannan–lignin polymers, microfibrillated cellulose, and glycerol.60 Also, multifunctional artificial materials with tunable mechanical performances and a propensity for self-healing have been created from nanofibrillated cellulose and cationic poly(vinyl amine) by mimicking the cell wall nanostructure.61

Moisture responses in wood are also being studied with the motivation to inspire new stimuli-responsive and multifunctional materials. Stimuli-responsive materials change according to the environment they are in and are designed to be sensitive to a variety of stimuli, such as temperature, heat, solvent, light, moisture, and electric or magnetic fields. Such materials have applications in areas as diverse as energy harvesting, sensors, drug delivery systems, biomimetic robotics, and artificial muscles.62 – 66 In trees, researchers have studied moisture-activated unidirectional movements, such as pine cone opening67 and bending of tree branches.68 Models have been developed relating these unidirectional movements to moisture-induced swelling in the amorphous components of wood cell walls and the cellular organization of wood tissue with different cellulose microfibril angles. Additionally, wood slivers consisting of a few softwood tracheids were found to be moisture-activated torsional actuators that can reversibly twist multiple revolutions per centimeter length and produce specific torque higher than that of an electric motor.55,69 The twist is caused by swelling between the helically wound cellulose microfibrils in the S2 secondary cell wall (Fig. 1f). The wood slivers also possess moisture-activated shape memory twist capabilities.55,69 Individual wood cell walls were also discovered to be moisture-activated materials for chemical transport. Ions implanted into cell walls were observed to diffuse only above a threshold MC.55,56 Both the shape memory and chemical transport thresholds are likely controlled by the moisture-dependent glass transition of hemicelluloses in the 60% to 80% RH range at room temperature.70 – 72 Glass transitions are often responsible for shape memory and stimuli-responsive behavior in polymers. When considered in bulk as a polymer, wood does not experience the macro-scale mechanical softening at the glass transition like other polymers, which is expected, given that wood must perform its mechanical functions above the MC-inducing glass transition in the living tree. An improved understanding of the wood cell wall nanostructure may lead to biomimetic polymer smart materials with improved mechanical properties.

Applications of Atomistic Simulations in Understanding Small-Scale Material Properties of Wood

Wood is a hierarchal material, and understanding its structure and properties requires thorough knowledge of material properties down to the nano- and molecular-scales. Many properties at these length scales cannot be assessed experimentally. Fortunately, numerical methods, such as atomistic simulations, are emerging as powerful tools at these small scales for simulating underlying physical and chemical mechanisms or predicting the thermodynamic properties of wood cell walls from the atomistic level. This motivates the use of molecular dynamics (MD) as it enables researchers to build bottom-up models starting from the chemical structure of the basic constituents of wood.

There has been much focus on understanding the structure and properties of crystalline nanocellulose because it is the primary nanoscale component responsible for the superb mechanical properties of wood. For example, united-atom MD simulations were used to quantify changes in different morphologies of cellulose to reveal that the semicrystalline phase may be an intermediate, kinetically arrested phase formed at amorphous cellulose formation.73 MD simulation showed in Iβ crystalline cellulose that elastic modulus, Poisson’s ratio, yield stress and strain, and ultimate stress and strain are highly anisotropic, and that although properties that describe elastic behavior of the material are independent of strain rate, yield and ultimate properties increase with increasing strain rate.74 In another MD study,75 the fracture energy of crystalline cellulose was found to depend on crystal width, due to edge defects that significantly reduce the fracture energy of small crystals but have a negligible effect beyond a critical width. Remarkably, ideal dimensions optimizing fracture energy are found to be similar to the common dimensions of crystalline nanocellulose found in nature, suggesting a natural optimization of structure.

Other researchers have focused on the assembly and interactions of wood polymers in the wood nanostructure because the overall material properties of wood are a direct function of these currently unknown nanostructures and interactions. Some of the earliest MD simulations studied interactions of lignin models with the surface of cellulose microfibrils. Attractions between lignin and cellulose microfibril surfaces that were observed suggested that the polysaccharide components of the cell wall may be influencing deposition of lignin.76 In another study, lignin adsorption was found to likely be dependent on crystal orientation of the microfibril.77 In a more recent study, bamboo molecular models of lignin, hemicellulose, and lignin carbohydrate complex (LCC) structures were used to study elastic moduli and adhesion energies between these materials and cellulose microfibril faces under dry conditions. It was shown that the hemicellulose model has stronger mechanical properties than lignin, whereas lignin exhibits greater tendency to adhere to cellulose microfibrils. The study suggested that the abundance of hydrogen bonds in hemicellulose chains is responsible for improving the mechanical behavior of LCC.

Overall, as the preceding examples of studies clearly show, atomistic simulations provide a platform for studying structures, interactions, and properties at the nano- and molecular scales. The role of simulations is expected to continue to increase as research increases. Nevertheless, because wood is such a complex and unknown material at these small scales, a key to increasing the potential benefits of simulations in forest products research will be developing appropriate experiments to further validate simulated results.

Sustainable Forest Management for Renewable Wood Resources

The sustainable management of forests is complex because it must consider not only the regeneration of trees harvested for material usage but also the maintenance of benefits that are both societal (e.g., recreation, food, and spiritual) and ecological (e.g., climate regulation, biodiversity, and protection of soil and water resources). Based on analyses of the Global Forest Resources Assessment 2015 of the Food and Agriculture Organization of the United Nations, forests reportedly cover 31% of the today’s world land surfaces78 and efforts to sustainably manage forests, including forest management certification programs, continue to increase worldwide.79 Certification programs came about to demonstrate the commercial viability of a “sustainable” alternative to historical practices that viewed forests as an infinite resource. Currently, about 10% of the world’s forests are in a certification program,79 and increased international awareness of and demand for chain of custody and supply chain verification in wood and wood products80 further supports a transition toward sustainable forest products production. With enhanced and interdisciplinary research into wood and wood products, we have the expectation that high-value products and feedstocks from forest materials will help increase the monetary value of forests and, thus, support their sustainable management.

Conclusion

The advancement of wood science is critical for the development of sustainable materials, fuels, and chemicals from forest resources. It is also invaluable to researchers who draw inspiration from the elegant, hierarchical structure of wood for developing advanced materials and structures. Numerous synergies exist between different research areas that should be exploited through multidisciplinary teams to accelerate efforts. For example, biorefinery researchers would benefit from improved biomimetic deconstruction pathways if the mechanisms used by decay fungi to deconstruct the recalcitrant wood cell walls into usable energy were better understood. Similarly, assuming controlling chemical transport through the cell wall is the key to preventing the onset of wood decay, a collaboration between researchers developing wood protection treatments and multifunctional smart chemical transport membranes would also be mutually beneficial. Such collaborations between seemingly different research areas are key to accelerating wood science and positioning it in the future with ample opportunity for innovative, meaningful contributions across a broad spectrum of material science research.

References

International Reference Life Cycle Data (ILCD): ILCD System Handbook - General Guide for Life Cycle Assessment - Detailed Guidance. EUR 24708 EN (Publications Office of the European Union, Luxemburg, 2010), http://publications.jrc.ec.europa.eu/repository/bitstream/JRC48157/ilcd_handbook-general_guide_for_lca-detailed_guidance_12march2010_isbn_fin.pdf. Accessed 11 April 2016.

M.A. Curran, Curr. Opin. Chem. Eng. 2, 273 (2013).

R. Bergman, M. Puettmann, A. Taylor, and K.E. Skog, For. Prod. J. 64, 220 (2014).

R. Sathre and J. O’Connor, Environ. Sci. Policy 13, 104 (2010).

R.J. Moon, G. Schueneman and J. Simonsen, JOM, 2016. doi:10.1007/s11837-016-2018-7.

A.C. Wiedenhoeft, Handbook of Wood Chemistry and Wood Composites, ed. R.M. Rowell (Boca Raton, FL: CRC Press, 2013), p. 9.

A. Panshin and C. Zeeuw, Textbook of Wood Techinology: Structure, Identification, Properties, and Uses of the Commercial Woods of the United States and Canada, 4th ed. (New York: McGraw-Hill, 1980).

N. Terashima, M. Yoshida, J. Hafrén, K. Fukushima, and U. Westermark, Holzforschung 66, 907 (2012).

D.J. Cosgrove and M.C. Jarvis, Front. Plant Sci. 3, 204 (2012).

N. Terashima, K. Kitano, M. Kojima, M. Yoshida, H. Yamamoto, and U. Westermark, J. Wood Sci. 55, 409 (2009).

A.N. Fernandes, L.H. Thomas, C.M. Altaner, P. Callow, V.T. Forsyth, D.C. Apperley, C.J. Kennedy, and M.C. Jarvis, Proc. Natl. Acad. Sci. U.S.A. 108, E1195 (2011).

J. Hafren, T. Fujino, T. Itoh, U. Westermark, and N. Terashima, Holzforschung 54, 234 (2000).

L. Salmen and I. Burgert, Holzforschung 63, 121 (2009).

R.M. Rowell, R. Petterson and M.A. Tshabalala, Handbook of Wood Chemistry and Wood Composites, ed. R.M. Rowell (Boca Raton, FL: CRC Press, 2013), p. 33.

S.V. Glass and S.L. Zelinka, Wood Handbook: Wood as an Engineering Material, ed. R.J. Ross (USDA Forest Service, Forest Products Laboratory, General Technical Report FPL- GTR-190, 2010), p. 4-1.

M.E. Himmel, S.-Y. Ding, D.K. Johnson, W.S. Adney, M.R. Nimlos, J.W. Brady, and T.D. Foust, Science 315, 804 (2007).

C.E. Wyman, B.E. Dale, R.T. Elander, M. Holtzapple, M.R. Ladisch, Y.Y. Lee, C. Mitchinson, and J.N. Saddler, Biotechnol. Prog. 25, 333 (2009).

J.J. Bozell, S.K. Black, M. Myers, D. Cahill, W.P. Miller, and S. Park, Biomass Bioenergy 35, 4197 (2011).

J.Y. Zhu, X.J. Pan, G.S. Wang, and R. Gleisner, Bioresour. Technol. 100, 2411 (2009).

R. Gupta, K.K. Sharma, and R.C. Kuhad, Bioresour. Technol. 100, 1214 (2009).

J.C. Serrano-Ruiz and J.A. Dumesic, Energy Environ. Sci. 4, 83 (2011).

J.J. Bozell and G.R. Petersen, Green Chem. 12, 539 (2010).

A.V. Bridgwater, J. Anal. Appl. Pyrolysis 51, 3 (1999).

C.C. Mukarakate, X. Zhang, A.R. Stanton, D.J. Robichaud, P.N. Ciesielski, K. Malhotra, B.S. Donohoe, E. Gjersing, R.J. Evans, D.S. Heroux, R. Richards, K. Iisa, and M.R. Nimlos, Green Chem. 16, 1444 (2014).

V.K. Venkatakrishnan, J.C. Degenstein, A.D. Smeltz, W.N. Delgass, R. Agrawal, and F.H. Ribeiro, Green Chem. 16, 792 (2014).

A.J. Minchener, Fuel 84, 2222 (2005).

J. Ahrenfeldt, T.P. Thomsen, U. Henriksen, and L.R. Clausen, Appl. Therm. Eng. 50, 1407 (2013).

A.J. Ragauskas, G.T. Beckham, M.J. Biddy, R. Chandra, F. Chen, M.F. Davis, B.H. Davison, R.A. Dixon, P. Gilna, M. Keller, P. Langan, A.K. Naskar, J.N. Saddler, T.J. Tschaplinski, G.A. Tuskan, and C.E. Wyman, Science 344, 709 (2014).

J.G. Linger, D.R. Vardon, M.T. Guarnieri, E.M. Karp, G.B. Hunsinger, M.A. Franden, C.W. Johnson, G. Chupka, T.J. Strathmann, P.T. Pienkos, and G.T. Beckham, Proc. Natl. Acad. Sci. U.S.A. 111, 12013 (2014).

I. Klein, B. Saha, and M.M. Abu-Omar, Catal. Sci. Technol. 5, 3242 (2015).

T. Parsell, S. Yohe, J. Degenstein, T. Jarrell, I. Klein, E. Gencer, B. Hewetson, M. Hurt, J.I. Kim, H. Choudhari, B. Saha, R. Meilan, N. Mosier, F. Ribeiro, W.N. Delgass, C. Chapple, H.I. Kenttämaa, R. Agrawal, and M.M. Abu-Omar, Green Chem. 17, 1492 (2015).

F. Derbyshire, M. Jagtoyen, and M. Thwaites, Porosity in Carbons: Characterization and Applications, ed. J.W. Patrick (London, U.K.: Edward Arnold, 1995), p. 209.

M.-M. Titirici, R.J. White, N. Brun, V.L. Budarin, D.S. Su, F. del Monte, J.H. Clark, and M.J. MacLachlan, Chem. Soc. Rev. 44, 250 (2015).

H. Jankowska, A. Świątkowski, and J. Choma, Active Carbon (Englewood Cliffs, NJ: Prentice-Hall, 1991).

Y. Uraki and K. Koda, J. Wood Sci. 61, 447 (2015).

J. Spender, A.L. Demers, X. Xie, A.E. Cline, M.A. Earle, L.D. Ellis, and D.J. Neivandt, Nano Lett. 12, 3857 (2012).

D.A. Baker, N.C. Gallego, and F.S. Baker, J. Appl. Polym. Sci. 124, 227 (2012).

S. Iijima, Nature 354, 56 (1991).

A.D. Maynard, P.A. Baron, M. Foley, A.A. Shvedova, E.R. Kisin, and V. Castranova, J. Toxicol. Environ. Health A 67, 87 (2004).

B. Goodell, X. Xie, Y. Qian, G. Daniel, M. Peterson, and J. Jellison, J. Nanosci. Nanotechnol. 8, 2472 (2008).

S. Lehmann, Sustainability 4, 2707 (2012).

M. Green and J. Karsh, TALL WOOD—The case for tall wood buildings, Report prepared for the Canadian Wood Council on behalf of the Wood Enterprise Coalition and Forest Innovation Investment, Vancouver, BC, 2012.

M. Mohammad, S. Gagnon, B. Douglas, and L. Podesto, Wood Des. Focus 22, 3 (2012).

N. Stark, Z. Cai and C. Carll, Wood Handbook: Wood as an Engineering Material, ed. R.J. Ross (USDA Forest Service, Forest Products Laboratory, General Technical Report FPL- GTR-190, 2010), p. 11-1.

F. Lam, M. Gehloff, and M. Closen, Proc. Inst. Civ. Eng Struct. Build. 163, 267 (2010).

A. Van Houtte, A. Buchanan, and P. Moss, Proceedings of the 8th World Conference on Timber Engineering (Lahti, Finland, 2004).

A. Buchanan and R. Fairweather, IPENZ Annual Conference 1993, Proceedings of Sustainable development (Wellington, New Zealand, 1993) p. 343

D. Mudarri and W. Fisk, Indoor Air 17, 226 (2007).

V. Arantes and B. Goodell, Deterioration and Protection of Sustainable Biomaterials. ACS Symp. 1158, 3 (2014).

S.T. Lebow, Wood Handbook: Wood as an Engineering Material, ed. R.J. Ross (USDA Forest Service, Forest Products Laboratory, General Technical Report FPL- GTR-190, 2010), p. 15-1.

S. Lebow, USDA Forest Service, Forest Products Laboratory, Research Paper FPL-RP-618 (2004).

R. Ringman, A. Pilgård, C. Brischke, and K. Richter, Holzforschung 68, 239 (2014).

C. Hill, Wood Modification: Chemical, Thermal and Other Processes (New York: Wiley, 2006).

S. Zelinka, S. Glass, and D. Stone, Wood Fiber Sci. 40, 544 (2008).

J.E. Jakes, N. Plaza, S.L. Zelinka, D.S. Stone, S.-C. Gleber, and S. Vogt, Proc. Of SPIE Vol. 9055, eds. A. Lakhtakia and R.J. Martin-Palma (2014), p. 90550 K.

S.L. Zelinka, S.-C. Gleber, S. Vogt, G.M. Rodríguez López, and J.E. Jakes, Holzforschung 69, 441 (2015).

J. Jakes, N. Plaza, D. Stone, and C. Hunt, J. For. Prod. Ind. 2, 10 (2013).

E.I.S. Flores, F.A. DiazDelaO, R.M. Ajaj, M.I. Friswell, and G.F. Fernando, Appl. Math. Model. 38, 3958 (2014).

L. Burns, A.P. Mouritz, D. Pook, and S. Feih, Compos. B Eng. 69, 222 (2015).

P. Oinonen, H. Krawczyk, M. Ek, G. Henriksson, and R. Moriana, Carbohydr. Polym. 136, 146 (2016).

R. Merindol, S. Diabang, O. Felix, T. Roland, C. Gauthier, and G. Decher, ACS Nano 9, 1127 (2015).

P.T. Mather, X.F. Luo, and I.A. Rousseau, Annu. Rev. Mater. Res. 39, 445 (2009).

C. Liu, H. Qin, and P.T. Mather, J. Mater. Chem. 17, 1543 (2007).

M.A.C. Stuart, W.T.S. Huck, J. Genzer, M. Müller, C. Ober, M. Stamm, G.B. Sukhorukov, I. Szleifer, V.V. Tsukruk, M. Urban, F. Winnik, S. Zauscher, I. Luzinov, and S. Minko, Nat. Mater. 9, 101 (2010).

C. de Las Heras Alarcon, S. Pennadam, and C. Alexander, Chem. Soc. Rev. 34, 276 (2005).

R. Vidoni, T. Mimmo, and C. Pandolfi, J. Bionic Eng. 12, 250 (2015).

C. Dawson, J.F.V. Vincent, and A.-M. Rocca, Nature 390, 668 (1997).

I. Burgert, M. Eder, N. Gierlinger, and P. Fratzl, Planta 226, 981 (2007).

N. Plaza, S.L. Zelinka, D.S. Stone, and J.E. Jakes, Smart Mater. Struct. 22, 072001 (2013).

S.S. Kelley, T.G. Rials, and W.G. Glasser, J. Mater. Sci. 22, 617 (1987).

W.J. Cousins, Wood Sci. Technol. 12, 161 (1978).

A.-M. Olsson and L. Salmén, The Softening Behavior of Hemicelluloses Related to Moisture (Washington, DC: American Chemical Society, 2003).

K. Kulasinski, S. Keten, S. Churakov, D. Derome, and J. Crmeliet, Cellulose 21, 1103 (2014).

X. Wu, R.J. Moon, and A. Martini, Cellulose 21, 2233 (2014).

R. Sinko, S. Mishra, L. Ruiz, N. Brandis, and S. Keten, ACS Macro Lett. 3, 64 (2014).

C.J. Houtman and R.H. Atalla, Plant Physiol. 107, 977 (1995).

S. Besombes and K. Mazeau, Plant Physiol. Biochem. 43, 299 (2005).

R.J. Keenan, G.A. Reams, F. Achard, J.V. de Freitas, A. Grainger, and E. Lindquist, For. Ecol. Manag. 352, 9 (2015).

K.G. MacDicken, P. Sola, J.E. Hall, C. Sabogal, M. Tadoum, and C. de Wasseige, For. Ecol. Manag. 352, 47 (2015).

E.E. Dormontt, M. Boner, B. Braun, G. Breulmann, B. Degen, E. Espinoza, S. Gardner, P. Guillery, J.C. Hermanson, G. Koch, S.L. Lee, M. Kanashiro, A. Rimbawanto, D. Thomas, A.C. Wiedenhoeft, Y. Yin, J. Zahnen, and A.J. Lowe, Biol. Conserv. 191, 790 (2015).

Acknowledgements

J.E.J. acknowledges funding from 2011 USDA PECASE awards. Financial support for P.N.C. was provided by the Computational Pyrolysis Consortium (CPC) funded by the Bioenergy Technologies Office (BETO) of the U.S. Department of Energy. We also thank Steve Schmeiding from the USDA Forest Products Laboratory for the photo used in Fig. 3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jakes, J.E., Arzola, X., Bergman, R. et al. Not Just Lumber—Using Wood in the Sustainable Future of Materials, Chemicals, and Fuels. JOM 68, 2395–2404 (2016). https://doi.org/10.1007/s11837-016-2026-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-2026-7