Abstract

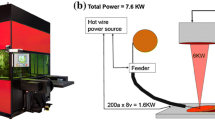

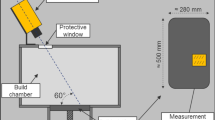

Understanding the thermal phenomena associated with direct laser deposition (DLD) is an important step toward obtaining ‘process–property–performance’ relationships for various designed parts and materials, as well as achieving increased process control for meeting application constraints. In this study, a thermally monitored laser engineered net shaping (LENS™) system was used with time-invariant (uncontrolled) build parameters to construct Ti-6Al-4V cylinders. During fabrication, the part’s thermal history and melt pool temperature were recorded via an in-chamber infrared camera and a dual-wavelength pyrometer, respectively. These tools demonstrate the use of non-destructive thermographic inspection for ensuring target part quality and/or microstructure. For the chosen part geometry, the melt pool was found to be approximately 40%–50% superheated during DLD, reaching temperatures as high as 2500°C. Temperature gradients varied and peaked around 1000°C/mm along the diameter of the relatively small cylinders. Cooling rates within the melt pool were found to increase as maximum melt pool temperature increased, for instance, from 12,000°C/s to 25,000°C/s. The post-DLD Ti-6Al-4V microstructure was found to vary from columnar near the substrate, or substrate-affected zone, to equiaxed approximately 2–3 mm from the substrate. Bulk heating of the part due to successive layer deposits was shown to promote α″ to an α + β decomposition, while prior-β grains were observed near and far from the substrate.

Similar content being viewed by others

References

M.L. Griffith, D.M. Keicher, C.L. Atwood, J.A. Romero, J.E. Smugeresky, L.D. Harwell, and D.L. Greene, in Proc. 7th Solid Free. Fabr. Symp. (1995), pp. 125–132.

J.E. Smugeresky, D.M. Keicher, J.A. Romero, M.L. Griffith, and L.D. Harwell, in World Congr. Powder Met. Part. Mater. (Chicago, IL, 1997).

M.L. Griffith, M.E. Schlienger, L.D. Harwell, M.S. Oliver, M.D. Baldwin, M.T. Ensz, M. Essien, J. Brooks, C.V. Robino, J.E. Smugeresky, W.H. Hofmeister, M.J. Wert, and D.V. Nelson, Mater. Des. 20, 107 (1999).

M.L. Griffith, M.T. Ensz, J.D. Puskar, C.V Robino, J.A. Brooks, J.Philliber, J.E. Smugeresky, and W.H. Hofmeister, in Mater. Res. Soc. Proc. (2000).

F.P. Jeantette, D.M. Keicher, J.A. Romero, and L.P. Schanwald, Patent #: US006046426A (2000).

U. Articek, M. Milfelner, and I. Anzel, Adv. Prod. Eng. Manag. 8, 169 (2013).

F. Wang, J. Mei, and X. Wu, J. Mater. Process. Technol. 195, 321 (2008).

W. Liu and J.N. DuPont, Scr. Mater. 48, 1337 (2003).

A. Bandyopadhyay, B.V. Krishna, W. Xue, and S. Bose, J. Mater. Sci. Mater. Med. 20, S29 (2009).

N. Shamsaei, A. Yadollahi, L. Bian, and S.M. Thompson, Addit. Manuf. 8, 12 (2015).

A.R. Nassar, J.S. Keist, E.W. Reutzel, and T.J. Spurgeon, Addit. Manuf. 6, 39 (2015).

L. Tang and R.G. Landers, ASME J. Manuf. Sci. Eng. 132, 011011 (2010).

L. Wang, S.D. Felicelli, and J.E. Craig, in Proc. 12th Solid Free. Fabr. Symp. (2007), pp. 100–111.

S.M. Thompson, L. Bian, N. Shamsaei, and A. Yadollahi, Addit. Manuf. 8, 36 (2015).

V. Neela and A. De, Int. J. Adv. Manuf. Technol. 45, 935 (2009).

L. Wang and S. Felicelli, Mater. Sci. Eng. A 435–436, 625 (2006).

G.J. Marshall, W.J. Young II, N. Shamsaei, J.Craig, T. Wakeman, and S.M. Thompson, in Proc. 26th Solid Free. Fabr. Symp. (Austin, USA, 2015).

M.L. Griffith, M.E. Schlienger, L.D. Harwell, M.S. Oliver, M.D. Baldwin, M.T. Ensz, E. Smugeresky, M. Essien, J. Brooks, C.V Robino, and D.V Nelson, in Proc. 9th Solid Free. Fabr. Symp. Austin, USA (1998), pp. 89–96.

R. Ye, J.E. Smugeresky, B. Zheng, Y. Zhou, and E.J. Lavernia, Mater. Sci. Eng. A 428, 47 (2006).

M. Gaumann, C. Bezencon, P. Canalis, and W. Kurz, Acta Mater. 49, 1051 (2001).

W. Hofmeister, M. Wert, J.E. Smugeresky, J.A. Philliber, and M.L. Griffith, JOM 51, 6 (1999).

L. Wang, S. Felicelli, Y. Gooroochurn, P.T. Wang, and M.F. Horstemeyer, Mater. Sci. Eng. A 474, 148 (2008).

J.E. Craig, T. Wakeman, R. Grylls, and J. Bullen, Sensors, Sampling, and Simulation for Process Control, ed. B.G. Thomas, J.A. Yurko, and L. Zhang (Hoboken, NJ: John Wiley & Sons, Inc., 2011), chap. 12. doi:10.1002/9781118061800.ch12.

G. Bi, A. Gasser, K. Wissenbach, A. Drenker, and R. Poprawe, Surf. Coatings Technol. 201, 2676 (2006).

S. Ocylok, E. Alexeev, S. Mann, A. Weisheit, K. Wissenbach, and I. Kelbassa, Phys. Procedia 56, 228 (2014).

S. Liu, P. Farahmand, and R. Kovacevic, Opt. Laser Technol. 64, 363 (2014).

G. Bi, A. Gasser, K. Wissenbach, A. Drenker, and R. Poprawe, Appl. Surf. Sci. 253, 1411 (2006).

G. Bi, A. Gasser, K. Wissenbach, A. Drenker, and R. Poprawe, Opt. Lasers Eng. 44, 1348 (2006).

J. Yang, S. Sun, M. Brandt, and W. Yan, J. Mater. Process. Technol. 210, 2215 (2010).

R.A. Wood and R.J. Favor, Titanium Alloys Handbook (Air Force Materials Laboratory, Wright-Patterson Air Force Base, Department of Defense Information Analysis Center, Ohio, 1972).

M. Labudovic and R. Kovacevic, in Inst. Mech. Eng. (2000), pp. 315–340.

M. Boivineau, Int. J. Thermophys. 27, 507 (2006).

M. Doubenskaia, M. Pavlov, S. Grigoriev, and I. Smurov, Surf. Coatings Technol. 220, 244 (2013).

E. Rodriguez, J. Mireles, C.A. Terrazas, D. Espalin, M.A. Perez, and R.B. Wicker, Addit. Manuf. 5, 31 (2015).

T. Purtonen, A. Kalliosaari, and A. Salminen, Phys. Procedia 56, 1218 (2014).

P. Hagqvist, F. Sikström, and A.K. Christiansson, Meas. J. Int. Meas. Confed. 46, 871 (2013).

L. Bian, S.M. Thompson, and N. Shamsaei, JOM 67, 629 (2015).

B. Torries, A. Sterling, N. Shamsaei, S.M. Thompson, and S.R. Daniewicz, J. Rapid Prototyp. 22, Special Issue of 2015 SFF Symposium (2016).

A. Sterling, B. Torries, N. Shamsaei, S.M. Thompson, and S.R. Daniewicz, in 26th Solid Free. Fabr. Symp. (Austin, TX, 2015).

M. Yan and P. Yu, in Sinter. Tech. Mater., edited by A. Lakshmanan (INTECH, 2015), pp. 77–106.

T. Wang, Y.Y. Zhu, S.Q. Zhang, H.B. Tang, and H.M. Wang, J. Alloys Compd. 632, 505 (2015).

P.A. Kobryn and S.L. Semiatin, J. Mater. Process. Technol. 135 (2–3), 330 (2003). doi:10.1016/S0924-0136(02)00865-8.

P.A. Kobryn, E.H. Moore, and S.L. Semiatin, Scr. Mater. 43, 299 (2000).

A. Bagheri, S. M. Thompson, and N. Shamsaei, in ASME Int. Mech. Eng. Congr. Expo. (Houston, TX, 2015).

A. Sterling, B. Torries, N. Shamsaei, S.M. Thompson, and D.W. Seely, Mater. Sci. Eng. A (2016). doi:10.1016/j.msea.2015.12.026.

S.A. Miller, P.R. Roberts, and A.S.M. Handbook, Powder Met. Technol. Appl. 7, 97 (1990).

A. Sterling, N. Shamsaei, B. Torries, and S.M. Thompson, in 6th Int. Conf. Fatigue Des. (Senlis, France, 2015).

S.R. Daniewicz, Fatigue Fract. Eng. Mater. Struct. 22 (4), 273 (1999). doi:10.1046/j.1460-2695.1999.00164.x.

B. Taylor and E. Weidmann, Application Notes—Metallagraphic Preparation of Titanium (Denmark: Struers, 2015). http://www.struers.com/default.asp?top_id=5&main_id=24&sub_id=185&doc_id=855.

Matweb: Material Property Data, TIMET 6-4 Titanium Alloy (Ti-6Al-4V; ASTM Grade 5) Rod (2015). http://www.matweb.com/search/DataSheet.aspx?MatGUID=f0d81a62a0564398b1b17e851841e0c4&ckck=1. Accessed Dec 2015.

D.P. Kennedy, J. Appl. Phys. 31, 1490 (1960).

J. Gockel and J. Beuth, in Solid Free. Fabr. Symp. (Austin, TX, 2013), pp. 666–674.

J. Sieniawski, W. Ziaja, K. Kubiak, and M. Motyka, in Titan. Alloy.—Adv. Prop. Control, edited by J. Sieniawski and W. Ziaja (INTECH, 2013), pp. 70–80.

Acknowledgements

The research presented here, including all fabrication and experimentation, was conducted at Mississippi State University’s Center for Advanced Vehicular Systems (CAVS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marshall, G.J., Young, W.J., Thompson, S.M. et al. Understanding the Microstructure Formation of Ti-6Al-4V During Direct Laser Deposition via In-Situ Thermal Monitoring. JOM 68, 778–790 (2016). https://doi.org/10.1007/s11837-015-1767-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1767-z