Abstract

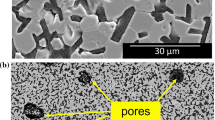

Graphite is used in high-temperature gas-cooled reactors because of its outstanding irradiation performance and corrosion resistance. To restrict its high-temperature (>873 K) oxidation, atmospheric-plasma-sprayed SiC-ZrB2-Al2O3-carbon nanotube (CNT) dual-layer coating was deposited on graphite substrate in this work. The effect of each layer was isolated by processing each component of the coating via spark plasma sintering followed by isothermal kinetic studies. Based on isothermal analysis and the presence of high residual thermal stress in the oxide scale, degradation appeared to be more severe in composites reinforced with CNTs. To avoid the complexity of analysis of composites, the high-temperature activation energy for oxidation was calculated for the single-phase materials only, yielding values of 11.8, 20.5, 43.5, and 4.5 kJ/mol for graphite, SiC, ZrB2, and CNT, respectively, with increased thermal stability for ZrB2 and SiC. These results were then used to evaluate the oxidation rate for the composites analytically. This study has broad implications for wider use of dual-layer (SiC-ZrB2/Al2O3) coatings for protecting graphite crucibles even at temperatures above 1073 K.

Similar content being viewed by others

References

I.B. Mason and R.H. Knibbs, The Young’s Modulus of Carbon and Graphite Artefacts, Carbon, 1967, 5(5), p 493-506

C. Yanhui, L. Hejun, F. Qiangang, S. Xiaohong, Q. Lehua, and W. Bingbo, Oxidation Protective and Mechanical Properties of SiC Nanowire-Toughened Si-Mo-Cr Composite Coating for C/C Composites, Corros. Sci., 2012, 58, p 315-320

N.S. Jacobson and D.M. Curry, Oxidation Microstructure Studies of Reinforced Carbon/Carbon Composite, Carbon, 2006, 44(7), p 1142-1150

Y.H. Chu, Q.G. Fu, C.W. Cao, H.J. Li, K.Z. Li, and Q. Lei, Microstructure and Oxidation Resistant Property of C/C Composites Modified by SiC-MoSi2-CrSi2, Surf. Eng., 2011, 27(5), p 355-361

Q.G. Fu, H.J. Li, Y.J. Wang, K.Z. Li, and X.H. Shi, B2O3 Modified SiC-MoSi2 Oxidation Resistant Coating for Carbon/Carbon Composites by a Two-Step Pack Cementation, Corros. Sci., 2009, 51(10), p 2450-2454

N.S. Jacobson, T.A. Leonhardt, D.M. Curry, and R.A. Rapp, Oxidative Attack of Carbon/Carbon Substrates Through Coating Pinholes, Carbon, 1999, 37, p 411-419

K. Fujii, J. Nakano, and M. Shindo, Improvement of the Oxidation Resistance of a Graphite Material by Compositionally Gradient SiC/C Layer, J. Nucl. Mater., 1993, 203(1), p 10-16

F.J. Buchanan and J.A. Little, Oxidation Protection of Carbon-Carbon Composites Using Chemical Vapour Deposition and Glaze Technology, Corros. Sci., 1993, 35(5-8), p 1243-1250

H.T. Tsou and W. Kowbel, A Hybrid PACVD SiC/CVD Si3N4/SiC Multilayer Coating for Oxidation Protection of Composites, Carbon, 1995, 33(9), p 1279-1288

J.N. Ness and T.F. Page, The Structure and Properties of Interfaces in Reaction-Bonded Silicon Carbides, Tailoring Multiph. Composite Ceram., 1986, p 347-356

S. Zhu, W.G. Fahrenholtz, G.E. Hilmas, and S.C. Zhang, Pressure Less Sintering of Carbon-Coated Zirconium Diboride Powders, Mater. Sci. Eng. A, 2007, 459(1-2), p 167-171

T. Feng, H.J. Li, X.H. Shi, X. Yang, and S.L. Wang, Oxidation and Ablation Resistance of ZrB2-SiC-Si/B-Modified SiC Coating for Carbon/Carbon Composites, Corros. Sci., 2013, 67, p 292-297

K. Balani, S.R. Bakshi, Y. Chen, T. Laha, and A. Agarwal, Role of Powder Treatment and Carbon Nanotube Dispersion in the Fracture Toughening of Plasma Sprayed Aluminum Oxide Carbon Nanotube Nanocomposite, J. Nanosci. Nanotechnol., 2007, 7, p 3553-3562

C.H. Chen and H. Awaji, Temperature Dependence of Mechanical Properties of Aluminum Titanate Ceramics, J. Eur. Ceram. Soc., 2007, 27(1), p 13-18

S. Ariharan, A. Gupta, A. Keshri, A. Agarwal, and K. Balani, Size Effect of Yttria Stabilized Zirconia Addition on Fracture Toughness and Thermal Conductivity of Plasma Sprayed Aluminum Oxide Composite Coatings, Nanosci. Nanotechnol. Lett., 2012, 4(3), p 323-332

K. Balani, A. Agarwal, and T. McKechnie, Near Net Shape Fabrication Via Vacuum Plasma Spray Forming, Trans. Indian Inst. Met., 2006, 2(59), p 237-244

M. Yu, O. Lourie, M.J. Dyer, K. Moloni, T.F. Kelly, and R.S. Ruoff, Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load, Science, 2000, 287, p 637-640

K. Balani, S. Bakshi, D. Lahiri, and A. Agarwal, Grain Growth Behavior of Aluminum Oxide Reinforced with Carbon Nanotube During Plasma Spraying and Post-Spray Consolidation, Int. J. Appl. Ceram. Technol., 2010, 7(6), p 846-855

Y. Chen, K. Balani, and A. Agarwal, Analytical Model to Evaluate Interface Characteristics of Carbon Nanotube Reinforced Aluminum Oxide Nanocomposites, Appl. Phys. Lett., 2008, 92(1), p 011916

J. Sun, L. Gao, and X. Jin, Reinforcement of Alumina Matrix with Multi-Walled Carbon Nanotubes, Ceram. Int., 2005, 31(6), p 893-896

J.Y. Huang, S. Chen, Z.Q. Wang, K. Kempa, Y.M. Wang, S.H. Jo, G. Chen, M.S. Dresselhaus, and Z.F. Ren, Superplastic Carbon Nanotubes, Nature, 2006, 439, p 281

F. Lupo, R. Kamalakaran, C. Scheu, N. Grobert, and M. Rühle, Microstructural Investigations on Zirconium Oxide-Carbon Nanotube Composites Synthesized by Hydrothermal Crystallization, Carbon, 2004, 42(10), p 1995-1999

W.-B. Tian, Y.-M. Kan, G.-J. Zhang, and P.-L. Wang, Effect of Carbon Nanotubes on the Properties of ZrB2-SiC Ceramics, Mater. Sci. Eng. A, 2008, 487(1-2), p 568-573

G.B. Yadhukulakrishnan, A. Rahman, S. Karumuri, M.M. Stackpoole, A.K. Kalkan, R.P. Singh, and S.P. Harimkar, Spark Plasma Sintering of Silicon Carbide and Multi-walled Carbon Nanotube Reinforced Zirconium Diboride Ceramic Composite, Mater. Sci. Eng. A, 2012, 552, p 125-133

S.R. Bakshi, K. Balani, and A. Agarwal, Thermal Conductivity of Plasma Sprayed Aluminum Oxide Multiwalled Carbon Nanotube Composites, J. Am. Ceram. Soc., 2008, 91(3), p 942-947

A. Nisar, S. Ariharan, and K. Balani, Synergistic Reinforcement of Carbon Nanotubes and Silicon Carbide for Toughening Tantalum Carbide Based Ultrahigh Temperature Ceramic, J. Mater. Res., 2016, 31(6), p 682-692

M. Asmani, C. Kermel, A. Leriche, and M. Ourak, Influence of Porosity on Young’s Modulus and Poisson’s Ratio in Alumina Ceramics, J. Eur. Ceram. Soc., 2001, 21(8), p 1081-1086

S. Zhu, W.G. Fahrenholtz, G.E. Hilmas, and S.C. Zhang, Pressureless Sintering of Carbon-Coated Zirconium Diboride Powders, Mater. Sci. Eng. A, 2007, 459(1), p 167-171

N.L. Okamoto, M. Kusakari, K. Tanaka, H. Inui, M. Yamaguchi, and S. Otani, Temperature Dependence of Thermal Expansion and Elastic Constants of Single Crystals of ZrB2 and the Suitability of ZrB2 as a Substrate for GaN Film, J. Appl. Phys., 2003, 93(1), p 88-93

A. Huntz, L. Maréchal, B. Lesage, and R. Molins, Thermal Expansion Coefficient of Alumina Films Developed by Oxidation of a FeCrAl Alloy Determined by a Deflection Technique, Appl. Surf. Sci., 2006, 252(22), p 7781-7787

A. Nisar, S. Ariharan, T. Venkateswaran, N. Sreenivas, and K. Balani, Oxidation Studies on TaC Based Ultra-High Temperature Ceramic Composites Under Plasma Arc Jet Exposure, Corros. Sci., 2016

L. Xiaowei, R.J. Charles, and Y. Suyuan, Effect of Temperature on Graphite Oxidation Behaviour, Nucl. Eng. Des., 2004, 227(3), p 273-280

J. Gallego, C. Batiot-Dupeyat, and F. Mondragón, Activation Energies and Structural Changes in Carbon Nanotubes During Different Acid Treatments, J. Therm. Anal. Calorim., 2013, 114(2), p 597-602 (in English)

J. Li, P. Eveno, and A.M. Huntz, Oxidation of SiC, Mater. Corros., 1990, 41(12), p 716-725

A.K. Kuriakose and J.L. Margrave, The Oxidation Kinetics of Zirconium Diboride and Zirconium Carbide at High Temperatures, J. Electrochem. Soc., 1964, 111(7), p 827-831

Acknowledgments

The authors acknowledge financial support from the Board of Research in Nuclear Sciences (BRNS), India (Grant No. 2013/36/12-BRNS/0736). K.B. acknowledges a P.K. Kelkar fellowship from the Indian Institute of Technology Kanpur. The authors acknowledge useful discussions with Dr. Kallol Mondal, IIT Kanpur, and Dr. L. Neelakantan, IIT Madras.

Author information

Authors and Affiliations

Corresponding author

Additional information

S. Ariharan and Pradyut Sengupta contributed equally as first author.

Appendix

Appendix

See Appendices A1, A2 and A3.

Schematic showing high temperature oxidation (dry atmosphere) of spark-plasma-sintered composites: (a) S20Z (top left: at room temperature, and bottom left: at ~1268 K), and (b) S20Z3C (top center: at room temperature, middle center: at ~873 K, and bottom center: at ~1268 K), and corresponding Raman spectrum (top right: before oxidation, bottom right: after oxidation)

Rights and permissions

About this article

Cite this article

Ariharan, S., Sengupta, P., Nisar, A. et al. Dual-Layer Oxidation-Protective Plasma-Sprayed SiC-ZrB2/Al2O3-Carbon Nanotube Coating on Graphite. J Therm Spray Tech 26, 417–431 (2017). https://doi.org/10.1007/s11666-016-0508-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0508-3