Abstract

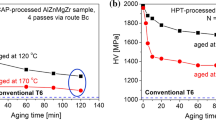

Coarse-grained Al-4wt.%Mg alloy with high stacking fault energy was deformed by high-pressure torsion (HPT) at room temperature. The HPT-induced grain refinement process of the alloy can be clarified as follows: (1) the randomly distributed dislocations firstly interact and rearrange to form dislocation cells; (2) with increasing the strain, these cell boundaries transform to small-angle grain boundaries that act as the dislocation sources, and therefore Shockley partial dislocations on the glide plane (111) can be easily emitted to accommodate plastic deformation; (3) along with the partial dislocations emission from low angle grain boundaries, the low angle grain boundaries gradually transform into the high angle grain boundaries. The relationship between the microstructural evolution and hardness was also investigated. It has been shown that the relationship between grain size and hardness deviates from the Hall-Petch linear relationship.

Similar content being viewed by others

References:

M.A. Meyers, A. Mishra, and D.J. Benson, Mechanical Properties of Nanocrystalline Materials, Prog. Mater. Sci., 2006, 51(4), p 427–556

R.Z. Valiev and T.G. Langdon, Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater. Sci., 2006, 51(7), p 881–981

A.P. Zhilyaev and T.G. Langdon, Using High-Pressure Torsion for Metal Processing: Fundamentals and Applications, Prog. Mater. Sci., 2008, 53(6), p 893–979

G. Liu, J. Gu, S. Ni, Y. Liu, and M. Song, Microstructural Evolution of Cu-Al Alloys Subjected to Multi-Axial Compression, Mater. Charact., 2015, 103, p 107–119

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R.G. Hong, Ultra-Fine Grained Bulk Aluminum Produced by Accumulative Roll-Bonding (ARB) Process, Scr. Mater., 1998, 39(9), p 1221–1227

M.I. Latypov, I.V. Alexandrov, Y.E. Beygelzimer, S. Lee, and H.S. Kim, Finite Element Analysis of Plastic Deformation in Twist Extrusion, Comput. Mater. Sci., 2012, 60, p 194–200

D. Orlov, Y. Beygelzimer, S. Synkov, V. Varyukhin, N. Tsuji, and Z. Horita, Plastic Flow, Structure and Mechanical Properties in Pure Al Deformed by Twist Extrusion, Mater. Sci. Eng. A, 2009, 519(1–2), p 105–111

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Bulk Nanostructured Materials from Severe Plastic Deformation, Prog. Mater. Sci., 2000, 45(2), p 103–189

Y. Estrin and A. Vinogradov, Extreme Grain Refinement by Severe Plastic Deformation: A Wealth of Challenging Science, Acta Mater., 2013, 61(3), p 782–817

M. Kawasaki, Different Models of Hardness Evolution in Ultrafine-Grained Materials Processed by High-Pressure Torsion, J. Mater. Sci., 2014, 49(1), p 18–34

I. Sabirov, M.Y. Murashkin, and R.Z. Valiev, Nanostructured Aluminium Alloys Produced by Severe Plastic Deformation: New Horizons in Development Mater, Sci. Eng. A, 2013, 560(2), p 1–24

C. Huang, K. Wang, S. Wu, Z. Zhang, G. Li, and S. Li, Deformation Twinning in Polycrystalline Copper at Room Temperature and Low Strain Rate, Acta Mater., 2006, 54(3), p 655–665

X. Liao, Y. Zhao, Y. Zhu, R. Valiev, and D. Gunderov, Grain-Size Effect on the Deformation Mechanisms of Nanostructured Copper Processed by High-Pressure Torsion, J. Appl. Phys., 2004, 96(1), p 636–640

Z. Wang, Y. Wang, X. Liao, Y. Zhao, E. Lavernia, Y. Zhu, Z. Horita, and T. Langdon, Influence of Stacking Fault Energy on Deformation Mechanism and Dislocation Storage Capacity in Ultrafine-Grained Materials, Scr. Mater., 2009, 60(1), p 52–55

M. Chen, E. Ma, K.J. Hemker, H. Sheng, Y. Wang, and X. Cheng, Deformation Twinning in Nanocrystalline Aluminum, Science, 2003, 300(5623), p 1275–1277

X. Liao, F. Zhou, E. Lavernia, S. Srinivasan, M. Baskes, D. He, and Y. Zhu, Deformation Mechanism in Nanocrystalline Al: Partial Dislocation Slip, Appl. Phys. Lett., 2003, 83(4), p 632–634

M. Liu, H. Roven, X. Liu, M. Murashkin, R. Valiev, T. Ungár, and L. Balogh, Grain Refinement in Nanostructured Al-Mg Alloys Subjected to HPT, J. Mater. Sci., 2010, 45(17), p 4659–4664

Z. Xu, N. Li, H. Jiang, and L. Liu, Deformation Nanotwins in Coarse-Grained Aluminum Alloy at Ambient Temperature and Low Strain Rate, Mater. Sci. Eng. A, 2015, 621, p 272–276

Y. Cao, Y.B. Wang, X.Z. Liao, M. Kawasaki, S.P. Ringer, T.G. Langdon, and Y.T. Zhu, Applied Stress Controls the Production of Nano-Twins in Coarse-Grained Metals, Appl. Phys. Lett., 2012, 101(23), p 231903-1–231903-5

Y. Estrin, A. Molotnikov, C.H.J. Davies, and R. Lapovok, Strain Gradient Plasticity Modelling of High-Pressure Torsion, J. Mech. Phys. Solids, 2008, 56(4), p 1186–1202

J.Y. Huang, Y.T. Zhu, H. Jiang, and T.C. Lowe, Microstructures and Dislocation Configurations in Nanostructured Cu Processed by Repetitive Corrugation and Straightening, Acta Mater., 2001, 49(9), p 1497–1505

X. Yang, S. Ni, and M. Song, Partial Dislocation Emission in a Superfine Grained Al-Mg Alloy Subject to Multi-axial Compression, Mater. Sci. Eng. A, 2015, 641, p 189–193

V. Yamakov, D. Wolf, S.R. Phillpot, A.K. Mukherjee, and H. Gleiter, Dislocation Processes in the Deformation of Nanocrystalline Aluminum by Molecular-Dynamic Simulation, Nat. Mater., 2002, 1(1), p 45–49

R.J. Asaro, P. Krysl, and B. Kad, Deformation Mechanism Transitions in Nanoscale FCC Metals, Philos. Mag. Lett., 2003, 83(12), p 733–743

Y. Zhu, X. Liao, and X. Wu, Deformation Twinning in Nanocrystalline Materials, Prog. Mater. Sci., 2012, 57(1), p 1–62

J. Wang and H. Huang, Shockley Partial Dislocations to Twin: Another Formation Mechanism and Generic Driving Force, Appl. Phys. Lett., 2004, 85(24), p 5983–5985

E. Hall, The Deformation and Ageing of Mild Steel: III, Discussion of Results, Proc. Phys. Soc. Lond. Sect. B, 1951, 643(9), p 747–752

N. Hansen, Hall-Petch Relation and Boundary Strengthening, Scr. Mater., 2004, 51(8), p 801–806

H.G.F. Wilsdorf and D. Kuhlmann-Wilsdorf, Work Softening and Hall-Petch Hardening in Extruded Mechanically Alloyed Alloys, Mater. Sci. Eng. A, 1993, 164(1–2), p 1–14

K.J. Kurzydłowski, B. Ralph, J.J. Bucki, and A. Garbacz, The Grain Boundary Character Distribution Effect on the Flow Stress of Polycrystals: The Influence of Crystal Lattice Texture, Mater. Sci. Eng. A, 1996, 205(1–2), p 127–132

R.W. Armstrong, Theory of the Tensile Ductile-Brittle Behavior of Poly-Crystalline HCP Materials, with Application to Beryllium, Acta Metall., 1968, 16(3), p 347–355

R. Armstrong, I. Codd, R. Douthwaite, and N. Petch, The Plastic Deformation of Polycrystalline Aggregates, Philos. Mag., 1962, 7(73), p 45–58

D. Wu, J. Zhang, J.C. Huang, H. Bei, and T.G. Nieh, Grain-Boundary Strengthening in Nanocrystalline Chromium and the Hall-Petch Coefficient of Body-Centered Cubic Metals, Scr. Mater., 2013, 68(2), p 118–121

L. Wang, H. Bei, T.L. Li, Y.F. Gao, E.P. George, and T.G. Nieh, Determining the Activation Energies and Slip Systems for Dislocation Nucleation in Body-Centered Cubic Mo and Face-Centered Cubic Ni Single Crystals, Scr. Mater., 2011, 65(3), p 179–182

Y.T. Zhu, X.Z. Liao, S.G. Srinivasan, Y.H. Zhao, M.I. Baskes, F. Zhou, and E.J. Lavernia, Nucleation and Growth of Deformation Twins in Nanocrystalline Aluminum, Appl. Phys. Lett., 2004, 85(21), p 5049–5051

Acknowledgments

The financial supports from National Natural Science Foundation of China (51531009), Grants from the Project of Innovation-driven Plan in Central South University (2015CXS003) and the outstanding graduate project of Advanced Non-ferrous Metal Structural Materials and Manufacturing Collaborative Innovation Center are appreciated. One of the authors (M. Song) would also thank the financial support from State Key Laboratory of Powder Metallurgy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, X., Yi, J., Ni, S. et al. Microstructural Evolution and Structure-Hardness Relationship in an Al-4wt.%Mg Alloy Processed by High-Pressure Torsion. J. of Materi Eng and Perform 25, 1909–1915 (2016). https://doi.org/10.1007/s11665-016-2044-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2044-1