Abstract

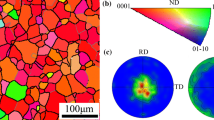

It is known that magnesium alloys can be rolled up to a large thickness reduction and develop a unique texture when the rolling speed is high (>1000 m/min). In order to understand the texture formation mechanism during high-strain-rate deformation, high-speed rolling of AZ31 magnesium alloy samples having different initial textures was conducted. The main components of the textures after the rolling were the RD-split basal, which consisted of 10°-20° inclining basal poles from the normal direction toward the rolling direction of the sheet, regardless of the different initial textures. With preheating at 473 K, all the samples were rolled without cracking while all were cracked when preheating was not applied. The optical micrographs and EBSD measurements showed a significant amount of twins and the cracks that developed along the shear bands consisted with laminated twins. Based on the texture simulation using the visco-plastic self-consistent model, it is concluded that the rapid development of the RD-split basal component from the initial basal alignment along the transverse direction was attributable to the tension twinning, \(\{10\bar{1}2\}\) \(\langle \bar{1}011\rangle .\) The effect of the initial texture on the crack formation can be explained by the activation of the twinning system.

Similar content being viewed by others

References

B.L. Mordike and T. Ebert, Magnesium Properties—Applications—Potential, Mater. Sci. Eng. A, 2001, 302, p 37–45

M.R. Barnett, M.D. Nave, and C.J. Bettles, Deformation Microstructures and Textures of Some Cold Rolled Mg Alloys, Mater. Sci. Eng. A, 2004, 386, p 205–211

H. Li, E. Hsu, J. Szpunar, H. Utsunomiya, and T. Sakai, Deformation Mechanism and Texture and Microstructure Evolution During High-Speed Rolling of AZ31B Mg Sheets, J. Mater. Sci., 2008, 43, p 7148–7156

H. Koh, T. Sakai, H. Utsunomiya, and S. Minamiguchi, Deformation and Texture Evolution During High-SPEED Rolling of AZ31 Magnesium Sheets, Mater. Trans., 2007, 48(8), p 2023–2027

S.R. Agnew and Ö. Duygulu, Plastic Anisotropy and the Role of Non-basal Slip in Magnesium Alloy AZ31B, Int. J. Plasticity, 2005, 21, p 1161–1193

M.R. Barnett, Twinning and the Ductility of Magnesium Alloys: Part I: “Tension” Twins, Mater. Sci. Eng. A, 2007, 464, p 1–7

M.R. Barnett, Twinning and the Ductility of Magnesium Alloys: Part II. “Contraction” Twins, Mater. Sci. Eng. A, 2007, 464, p 8–16

R. Gehrmann, M.M. Frommert, and G. Gottstein, Texture Effects on Plastic Deformation of Magnesium, Mater. Sci. Eng. A, 2005, 395, p 338–349

T. Al-Samman, Comparative Study of the Deformation Behavior of Hexagonal Magnesium-Lithium Alloys and a Conventional Magnesium AZ31 Alloy, Acta Mater., 2009, 57, p 2229–2242

T. Al-Samman and G. Gottstein, Dynamic Recrystallization During High Temperature Deformation of Magnesium, Mater. Sci. Eng. A, 2008, 488, p 406–414

J. Kim, K. Okayasu, and H. Fukutomi, Formation of Texture in AZ80 During High Temperature Compression Deformation, Mater. Sci. Forum, 2013, 753, p 493–496

M. Marya, L.G. Hector, R. Verna, and W. Tong, Microstructural Effects of AZ31 Magnesium Alloy on Its Tensile Deformation and Failure Behaviors, Mater. Sci. Eng. A, 2006, 418, p 341–356

K. Helming, M. Lyubchenko, B. He, and U. Preckwinkel, A New Method for Texture Measurements Using a General Area Detector Diffraction System, Powder Diffr., 2003, 18(2), p 99–102

K. Pawlik, J. Pospiech, and K. Lücke, The ODF Approximation from Pole Figures with the Aid of the ADC Method, Texture Micrstruct., 1991, 14–18, p 25–30

R.A. Lebensohn and C.N. Tomé, A Self-Consistent Anisotropic Approach for the Simulation of Plastic Deformation and Texture Development of Polycrystals: Application to Zirconium Alloys, Acta Metall. Mater., 1993, 41(9), p 2611–2624

C.N. Tomé, R.A. Lebensohn, and U.F. Kocks, A Model for Texture Development Dominated by Deformation Twinning: Application to Zirconium Alloys, Acta Metall. Mater., 1991, 39(11), p 2667–2680

S. Sandlöbes, S. Zaefferer, I. Schestakow, S. Yi, and R. Gonzalez-Martinez, On the Role of Non-basal Deformation Mechanisms for the Ductility of Mg and Mg-Y Alloys, Acta Mater., 2011, 59, p 429–439

J. Koike, Y. Sato, and D. Ando, Origin of the Anomalous (1012) Twinning During Tensile Deformation of Mg Alloy Sheet, Mater. Trans., 2008, 49(12), p 2792–2800

A. Styczynski, C. Hartig, J. Bohlen, and D. Letzig, Cold Rolling Textures in AZ31 Wrought Magnesium Alloy, Scr. Mater., 2004, 50, p 943–947

H. Takuda, H. Fujimoto, and N. Hatta, Modelling on Flow Stress of Mg-Al-Zn Alloys at Elevated Temperatures, J Mater. Process. Technol., 1998, 80–81, p 513–516

H. Asgari, A.G. Odeshi, and J.A. Szpunar, Plastic Anisotropy and Texture Evolution in Rolled AZ31B Magnesium Alloy Under Dynamic Shock Loading, Proceedings of the 16th Werkstofftechnischen Kolloquium, Chemnitz, Germany, 2013

L. Helis, K. Okayasu, and H. Fukutomi, Microstructure Evolution and Texture Development During High-Temperature Uniaxial Compression of Magnesium Alloy AZ31, Mater. Sci. Eng. A, 2006, 430, p 98–103

W.B. Hutchinson and M.R. Barnett, Effective Values of Critical Resolved Shear Stress for Slip in Polycrystalline Magnesium and Other hcp Metals, Scr. Mater., 2010, 63, p 737–740

M. Sanjari, A. Farzadfar, M. Hattori, A. Muraoka, T. Sakai, H. Utsunomiya, E. Essadiqi, I.-H. Jung and S. Yue, Microstructure and Texture Evolution of Mg-3%Al-1%Zn and Mg-Zn-Ce Mg Alloy Sheets Processed by High Speed Rolling, Mg2012: 9th International Conference on Magnesium Alloys and Their Applications, W.J. Poole and K.U. Kainer, Ed., Jul 8-12, 2012 (Vancouver, Canada), p 375–384

Acknowledgments

The authors would like to acknowledge Mr. Miyamoto, Osaka University, for helping with the high-speed rolling experiment. We thank Mr. Asgari and Mr. Ouellet for valuable discussion and providing language help. We also thank Professor Tomé for providing the code of VPSC-7. The project was supported by Auto21, Canadian Network of Centers of Excellence.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Onuki, Y., Hara, K., Utsunomiya, H. et al. High-Speed Rolling of AZ31 Magnesium Alloy Having Different Initial Textures. J. of Materi Eng and Perform 24, 972–985 (2015). https://doi.org/10.1007/s11665-014-1318-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1318-8