Abstract

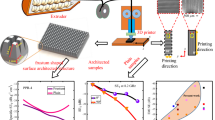

Material-extrusion three-dimensional (3D) printing has recently attracted much interest because of its process flexibility, rapid response to design alterations, and ability to create structures “on-the-go”. For this reason, 3D printing has possible applications in rapid creation of space-based devices, for example cube satellites (CubeSat). This work focused on fabrication and characterization of tungsten-doped polycarbonate polymer matrix composites specifically designed for x-ray radiation-shielding applications. The polycarbonate–tungsten polymer composite obtained intentionally utilizes low loading levels to provide x-ray shielding while limiting effects on other properties of the material, for example weight, electromagnetic functionality, and mechanical strength. The fabrication process, from tungsten functionalization to filament extrusion and material characterization, is described, including printability, determination of x-ray attenuation, tensile strength, impact resistance, and gigahertz permittivity, and failure analysis. The proposed materials are uniquely advantageous when implemented in 3D printed structures, because even a small volume fraction of tungsten has been shown to substantially alter the properties of the resulting composite.

Similar content being viewed by others

References

D. Espalin, D. Muse, E. MacDonald, and R. Wicker, Int. J. Adv. Manuf. Technol. 72, 963–978 (2014).

C. Rocha, A. Torrado-Perez, D.A. Roberson, C. Shemelya, E. MacDonald, and R. Wicker, J. Mater. Res. 29, 1859–1866 (2014).

A. Torrado-Perez, D.A. Roberson, and R.B. Wicker, J. Fail. Anal. Prev. 14, 343–353 (2014).

E. Aguilera, J. Ramos, D. Espalin, F. Cedillos, D. Muse, R. Wicker, and E. MacDonald, In Proceedings of Solid Freeform Fabrication Symposium, pp. 950–961 (2013).

A. Lopes, M. Navarrete, F. Medina, J. Palmer, E. MacDonald, and R. Wicker, In Proceedings of 17th Solid Freeform Fabrication Symposium, pp. 644–655 (2006).

R.B. Wicker, F. Medina, and C. Elkins, In Proceedings of 15th Solid Freeform Fabrication Symposium, pp. 754–764 (2004).

F. Medina, A. Lopes, A. Inamdar, R. Hennessey, J. Palmer, B. Chavez, D. Davis, P. Gallegos, and R. Wicker, In Proceedings of 16th Solid Freeform Fabrication Symposium, pp. 39–49 (2005).

A.J. Lopes, E. MacDonald, and R. Wicker, Rapid Prototyp. J. 18, 129–143 (2012).

J.A. Palmer, B. Jokiel, C.D. Nordquist, B.A. Kast, C.J. Atwood, E. Grant, F.J. Livingston, F. Medina, and R.B. Wicker, Rapid Prototyp. J. 12, 148–155 (2006).

M. Navarrete, A. Lopes, J. Acuna, R. Estrada, E. MacDonald, J. Palmer, and R. Wicker, In Proceedings of 18th Solid Freeform Fabrication Symposium, pp. 575–585 (2007).

D. Periard, E. Malone, and H. Lipson, In Proceedings of 17th Solid Freeform Fabrication Symposium, pp. 503–512 (2007).

E. DeNava, M. Navarrete, A. Lopes, M. Alawneh, M. Contreras, D. Muse, S. Castillo, E. MacDonald, and R. Wicker, In Proceedings of 19th Solid Freeform Fabrication Symposium, pp. 362–369 (2008).

C. Gutierrez, R. Salas, G. Hernandez, D. Muse, R. Olivas,E. MacDonald, M.D. Irwin, R. Wicker, M. Newton, K. Church, and B. Zufelt, In Proceedings of 2011 IMAPS Symposium (2012).

D.A. Roberson, R.B. Wicker, and E. MacDonald, J. Electron. Mater. 41, 2553–2566 (2012).

R.B. Wicker, F. Medina, E. MacDonald, D.W. Muse, and D. Espalin, U. S. Patent Pending (Application 13/343,651—3/14/2013).

R.B. Wicker, F. Medina, E. MacDonald, D.W. Muse, and D. Espalin, U. S. Patent Pending (Application 13/829,723—3/14/2013).

E. MacDonald, R. Salas, D. Espalin, M. Perez, E. Aguilera, D. Muse, and R. Wicker, Access IEEE 2, 1–12 (2013). doi:10.1109/ACCESS.2014.2311810.

C. Shemelya, F. Cedillos, E. Aguilera, E. Maestas, D. Espalin, D. Muse, R. Wicker, and E. MacDonald, In Proceedings of 2013 IEEE Sensing, pp. 1–4 (2013).

C. Shemelya, F. Cedillos, E. Aguilera, D. Espalin, D. Muse, R. Wicker, and E. MacDonald, IEEE Sens. J. 15, 1280–1286 (2014). doi:10.1109/JSEN.2014.2356973.

D.A. Roberson, R.B. Wicker, and E. MacDonald, Mater. Lett. 76, 51–54 (2012).

R.B. Wicker and E.W. MacDonald, Virtual Phys. Prototyp. 7, 181–194 (2012).

D. Askeland, P. Fulay, and W. Wright, The Science and Engineering of Materials, SI ed. (Stamford: Cengage Learning, 2011), p. 661.

M.Z. Ronga, M.Q. Zhang, Y.X. Zheng, H.M. Zeng, R. Walter, and K. Friedrich, Polym. 42, 167–183 (2001).

C.L. Wu, M.Q. Zhang, M.Z. Rong, and K. Friedrich, Compos. Sci. Technol. 62, 1327–1340 (2002). doi:10.1016/S0266-3538(02)00079-9.

B.D. Cullity, Elements of X-ray Diffraction, 2nd ed. (Reading: Addison Wesley, 1978).

S.C. Tjong, Mater. Sci. Eng. R 53, 73–197 (2006).

Y. Xie, C.A.S. Hill, Z. Xiao, H. Militz, and C. Mai, Compos. A 41, 806–819 (2010).

S.-Y. Fu, X.-Q. Feng, B. Lauke, and Y.-W. Mai, Compos. B 39, 933–961 (2008).

ASTM Standard D792-13 (2013).

B.N. Jang and C.A. Wilkie, Thermochim. Acta 426, 73–84 (2005).

W. Zhoua, H. Yang, and J. Zhou, J. Anal. Appl. Pyrolysis 78, 413–418 (2007).

N.Z. Noor Azman, S.A. Siddiqui, R. Hart, and I.M. Low, Appl. Radiat. Isot. 71, 62–67 (2013).

E.B. Saloman, J.H. Hubbell, and J.H. Scofield, Atom. Data Nucl. Data Tables 38, 1–197 (1988).

J.H. Hubbell and S.M. Seltzer, Tables of x-ray mass attenuation coefficients and mass energy-absorption coefficients, version 1.4 (National Institute of Standards and Technology 2004), http://physics.nist.gov/xaamdi. Accessed 29 Jan 2015.

M.F. Garbauskas, Handbook of Polycarbonate Science and Technology, ed. J.T. Bendler (CRC Press, New York, 1999), p. 294.

ASTM Standard D638-10 (2010).

ASTM Standard D256-10 (2010).

A. Sihvola, IEEE Electromagn. Waves Ser. 47 (IEE Press, London, 1999).

L. Wang, R. Zhou, and H. Xin, IEEE Trans. Microw. Theory Technol. 56, 499–506 (2008).

M. Liang, Z. Wu, L. Chen, L. Song, P. Ajayan, and H. Xin, IEEE Trans. Microw. Theory Technol. 59, 2719–2725 (2011).

Acknowledgements

We would like to thank the Intelligence Community Postdoctoral Research Fellowship Program, The University of Texas at El Paso, the W. M. Keck Center for 3D Innovation, the University of Arizona, COSMIAC, and NASA Glenn Research Center. The research presented here was performed as a result of funding in part from The America Makes Manufacturing Initiative, the State of Texas Emerging Technology Fund, the National Aeronautics and Space Administration under grant number NNX13AB53G, AFOSR YIP under grant number FA9550-14-1-0260, the National Science Foundation under awards 0823864 and 0925220, and the state of Arizona under TRIF.

This project was supported by a grant from the Intelligence Community Postdoctoral Research Fellowship Program through funding from the Office of the Director of National Intelligence. All statements of fact, opinion, or analysis expressed are those of the authors and do not reflect the official positions or views of the Intelligence Community or of any other US Government agency. Nothing in the contents should be construed as asserting or implying US Government authentication of information or Intelligence Community endorsement of the author’s views.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shemelya, C.M., Rivera, A., Perez, .T. et al. Mechanical, Electromagnetic, and X-ray Shielding Characterization of a 3D Printable Tungsten–Polycarbonate Polymer Matrix Composite for Space-Based Applications. J. Electron. Mater. 44, 2598–2607 (2015). https://doi.org/10.1007/s11664-015-3687-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-3687-7