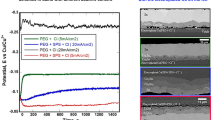

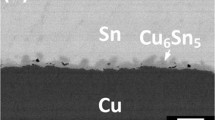

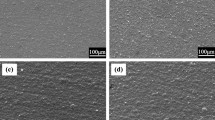

“Kirkendall voiding” in the interfacial Cu3Sn intermetallic compound is often observed in solder joints made between Sn-containing alloys and Cu interconnect pads, during extended thermal aging or electromigration testing. It is commonly believed that voids arise from the Kirkendall effect, i.e., the imbalance of diffusion fluxes of Cu and Sn atoms in Cu3Sn. However, recent studies have demonstrated that the propensity for voiding is greatly affected by the amount of organic impurities incorporated during Cu electroplating. The level of impurities was shown to depend on various electroplating parameters, such as current density, bath temperature, bath age, etc. In this study, a general picture is proposed to provide a better understanding of the effect of electroplating process parameters on Cu3Sn voiding. The picture correlates the level of impurity incorporation to (1) the applied electroplating overpotential, and (2) the crystallographic orientation of the Cu deposit. As a first-order approximation, the picture is supported by a variety of electroplating experiments, secondary-ion mass spectroscopy (SIMS), and x-ray diffraction (XRD) analysis.

Similar content being viewed by others

References

K. Zeng, R. Stierman, T. Chui, D. Edward, K. Ano, and K.N. Tu, J. Appl. Phys. 97, 024508 (2005).

T. Mattila and J. Kivilahti, J. Electron. Mater. 35, 250 (2006).

L. Xu, J. Pang, and F. Che, J. Electron. Mater. 37, 880 (2008).

J. Yu and J. Kim, Acta Mater. 56, 5514 (2008).

B. Chao, S. Chae, X. Zhang, K. Lu, M. Ding, J. Im, and P.J. Ho, J. Appl. Phys. 100, 084909 (2006).

J.W. Nah, J.O. Suh, and K.N. Tu, J. Appl. Phys. 100, 123513 (2006).

Y.C. Liu, J.T. Chen, Y.C. Chuang, L. Ke, and S.J. Wang, Appl. Phys. Lett. 90, 112114 (2007).

Y.S. Lai, Y.T. Chiu, and J. Chen, J. Electron. Mater. 37, 1624 (2008).

B. Pieraggi, R.A. Rapp, F.J.J. van Loo, and J.P. Hirth, Acta Metall. Mater. 38, 1781 (1990).

L. Yin and P. Borgesen, J. Mater. Res. 26, 455 (2011).

D.W. Henderson, P. Borgesen, L. Yin, and P. Kondos (in preparation).

A. Paul, C. Gosh, and W.J. Boettinger, Metall. Mater. Trans. A 42, 952 (2011).

W. Yang, R.W. Messler, and L.E. Felton, J. Electron. Mater. 23, 250 (1994).

T. Laurila, V. Vuorinen, and J.K. Kivilahti, Mater. Sci. Eng. R 49, 1 (2005).

P.L. Liu and J.K. Shang, Scripta Mater. 53, 631 (2005).

Y.W. Wang, Y.W. Lin, and C.R. Kao, Microelectron. Reliab. 49, 248 (2009).

D.A. Porter and K.E. Easterling, Phase Transformations in Metals and Alloys, 2nd ed. (Boca Raton: CRC, 1992), p. 79.

Y. Liu, J. Wang, L. Yin, P. Kondos, C. Parks, P. Borgesen, D.W. Henderson, E.J. Cotts, and N. Dimitrov, J. Appl. Electrochem. 38, 1695 (2008).

F. Wafula, Y. Liu, L. Yin, S. Bliznakov, P. Borgesen, E.J. Cotts, and N. Dimitrov, J. Electrochem. Soc. 157, D111 (2009).

Y. Liu, L. Yin, S. Bliznakov, P. Kondos, P. Borgesen, D.W. Henderson, C. Parks, J. Wang, E.J. Cotts, and N. Dimitrov, IEEE Trans. Compon. Pack. Technol. 33, 127 (2010).

F. Wafula, Y. Liu, L. Yin, S. Bliznakov, P. Borgesen, E.J. Cotts, and N. Dimitrov, J. Appl. Electrochem. 41, 469 (2011).

S. Kumar, C.A. Handwerker, X. Nie, J. Smetana, D. Love, J. Watkowski, R. Martinez, and R. Parker, in Proceedings of SMTAI Conference (2008), p. 876.

H.D. Merchant, W.C. Liu, L.A. Giannuzzi, and J.G. Morris, Mater. Charact. 53, 335 (2004).

W. Zhang, S.H. Brongersma, T. Conard, W. Wu, M. Van Hove, W. Vandervorst, and K. Maex, Electrochem. Solid-State Lett. 8, C95 (2005).

M. Stangl, V. Dittel, J. Acker, V. Hoffmann, W. Gruner, S. Strehle, and K. Wetzig, Appl. Surf. Sci. 252, 158 (2005).

L. Yin, P. Kondos, P. Borgesen, Y. Liu, S. Bliznakov, F. Wafula, N. Dimitrov, D. Henderson, C. Parks, M. Gao, J. Therriault, J. Wang, and E. Cotts, in Proceedings of 59th Electronic Components and Technology Conference (ECTC) (2009), p. 406.

J.P. Healy and D. Pletcher, J. Electroanal. Chem. 338, 155 (1992).

Z.V. Feng, X. Li, and A.A. Gewirth, J. Phys. Chem. B 107, 9415 (2003).

M. Alodan and W.H. Smyrl, J. Electrochem. Soc. 145, 957 (1998).

T.P. Moffat, D. Wheeler, and D. Josell, J. Electrochem. Soc. 151, C262 (2004).

J.O’.M. Bockris, A.K.N. Reddy, and M. Gamboa-Aldeco, Morden Electrochemistry 2A: Fundamentals of Electrodics, 2nd ed. (New York: Kluwer, 2000), p. 974.

C.S. Barrett and T.B. Massalski, Structure of Metals: Crystallographic Methods, Principles, and Data (Oxford: Pergamon, 1980), p. 204.

T. Swanson, Natl. Bur. Stand. (U.S.) Circ. 539,1,15 (1953).

Z.D. Schultz, Z. Feng, M.E. Biggin, and A.A. Gewirth, J. Electrochem. Soc. 153, C97 (2006).

M.J. Willey and A.C. West, J. Electrochem. Soc. 154, C156 (2007).

M. Tan, C. Guymon, D.R. Wheeler, and J.N. Harb, J. Electrochem. Soc. 154, D78 (2007).

C. Liu, Y. Wang, M. Tsai, H. Feng, S. Chang, and G. Hwang, J. Vac. Sci. Technol. A 23, 658 (2005).

S. Chang, J. Shieh, B. Dai, M. Feng, and Y. Li, J. Electrochem. Soc. 149, G535 (2002).

M. Yoon, Y. Park, and Y. Joo, Thin Solid Films 408, 230 (2002).

A. Hamelin, T. Vitanov, E. Sevastyanov, and A. Popov, J. Electroanal. Chem. 145, 225 (1983).

W.P. Dow, M.Y. Yen, W. Lin, and S. Ho, J. Electrochem. Soc. 152, C769 (2005).

S. Kim, J. Jang, J. Lee, and D.J. Duquette, Electrochim. Acta 52, 5258 (2007).

B. Hong, C. Jiang, and X. Wang, Powder Diffr. 22, 324 (2007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yin, L., Wafula, F., Dimitrov, N. et al. Toward a Better Understanding of the Effect of Cu Electroplating Process Parameters on Cu3Sn Voiding. J. Electron. Mater. 41, 302–312 (2012). https://doi.org/10.1007/s11664-011-1764-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-011-1764-0