Abstract

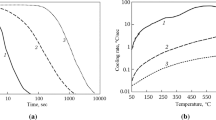

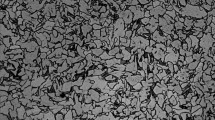

A study of the hardenability, the microstructure and the phase transformations as a function of the cooling rate, of a marine crankshaft S34MnV steel has been performed using a Jominy end-quench test and dilatometry tests. The cooling rate has a distinct influence on the hardness and microstructure characteristics. As the cooling rate decreases, the hardness drops from HRC53 at the quenched end to HRC22 at the top end of the Jominy bar. The corresponding microstructures change from hard martensite to bainite, then soft pearlite and ferrite. The critical temperatures Ac1, 740 °C and Ac3, 830 °C were determined, and a continuous cooling transformation diagram was constructed from the dilatometric data. The important role of cooling rate on final hardness, phase transformation and microstructures are analyzed.

Similar content being viewed by others

References

Chen ZY and Nash P (2018) Steel Res. Int. 89(3), 1700321

M.Y. Sun, B. Xu, D.Z. Li and Y.Y. Li: AIP Conf. Proc., 2013, vol. 1532, pp. 898-904.

A. Milenin, T. Rec, W. Walczyk and M. Pietrzyk: Procedia Eng., 2014, vol. 81, pp.498-503.

M. Çakir and A. Özsoy: Mater. Des., 2011, vol. 32, pp. 3099-3105.

F.A. Franco, M.F.R. González, M.F. de Campos, and L.R. Padovese: J Nondestruct Eval, 2013, vol. 32, pp. 93-103.

S. Hadi, E. Widiyono, W. Winarto and D.Z. Noor: J. Technol. Sci. (The Journal for Technology and Science), 2013, vol. 24, pp. 7-12.

D.O. Fernandino, J.M. Massone and R.E. Boeri: J. Mater. Process. Technol., 2013. vol. 213, pp. 1801-1809.

A.B. Dobuzhskaya, G. A. Galitsyn, N. V. Mukhranov, M. S. Fomichev, E. V. Belokurova and S. V.Belikov: Steel Transl., 2015, vol. 45, pp. 894-899.

Zheng YX, Wang FM, Li CR, He YT (2017) Mater. Sci. Eng., A 701, pp. 45-55.

K.N. Campo, D.R. Andrade, V.C. Opini, M.G. Mello, E.S.N. Lopes and R. Caram: J. Alloys Compd., 2016, vol. 667, pp. 211-218.

J. Lapin and K. Marek: J. Alloys Compd., 2018. vol.735, pp. 338-348.

Y. Yin, B.H. Luo, H.B. Jing, Z.H. Bai and Y. Gao: Metall. Mater. Trans. B, 2018. vol. 49B, pp. 2241-2251.

H.Y. Wu, Z.W. Huang, N. Zhou, J.G. Chen, P. Zhou and L. Jiang (2019) Mater. Sci. Eng., A, vol. 739, pp. 473-479.

M. Gomez, L. Rancel, E. Escudero and S.F. Medina: J. Mater. Sci. Technol., 2014, vol. 30, pp. 511-516.

Kawulok R, Schindler I, Kawulok P, Rusz S, Opěla P, Solowski Z, Čmiel KM (2015) Metalurgija, vol. 54, pp. 473–476.

H.P. Kang, B.J. Park, J.H. Jang, K.S. Jang and K.J. Lee: Met. Mater. Int., 2016, vol. 22, pp. 949-955.

M.Y. Sun, S.P. Lu, S.J. Li, D.Z. Li and Y.Y. Li: Adv. Mater. Res., 2007, vol. 26-28, pp. 1037-1040.

M. Kawuloková, B. Smetana, S. Zlá, A. Kalup, E. Mazancová, P. Váňová, P. Kawulok, J. Dobrovská and S. Rosypalová: J. Therm. Anal. Calorim., 2017, vol. 127, pp. 423-429.

C.R.N. Nunura, C.A. dos Santos and J.A. Spim: Mater. Des., 2015, vol. 76, pp. 230-243.

A. Çalik: Int. J. Phys. Sci., 2009, vol. 4, pp. 514-518.

Yazdi AZ, Sajjadi SA, Zebarjad SM (2008) J. Mater. Process. Technol. vol. 199, pp. 124-129.

B. P. Smoljan: J. Mater. Process. Technol,. 2006, vol. 175, pp. 393-397.

H. Kitahara, R. Ueji, N. Tsuji and Y. Minamino: Acta Mater., 2006, vol. 54, pp. 1279-1288.

M. Kumar, N. Ross and I. Baumgartner: Mater. Sci. Forum, 2015, vol. 828-829, pp. 188-193.

Acknowledgments

The authors would like to thank the Thermal Processing Technology Center (TPTC) of Illinois Institute of Technology for supporting this work, and thanks to Russ Janota, Yang Zhou, and Kathy Ho for their help in experimentation. This work was supported by Shanghai Heavy Castings and Forgings Collaborative Innovation Center (Grant Numbers ZF1225); Innovation Program of Shanghai Municipal Education Commission (Grant Numbers 12YZ183).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 10, 2018.

Rights and permissions

About this article

Cite this article

Chen, Z., Nash, P. & Zhang, Y. Correlation of Cooling Rate, Microstructure and Hardness of S34MnV Steel. Metall Mater Trans B 50, 1718–1728 (2019). https://doi.org/10.1007/s11663-019-01621-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01621-0