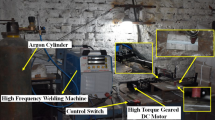

Scrap-based electric arc furnace (EAF) steelmaking is limited by a surface cracking problem in the recycled steel products, which is known as surface hot shortness. This problem originates from the excessive amount of copper (Cu) in the steel scrap, which enriches during the oxidation of iron (Fe) and consequently melts and penetrates into the austenite grain boundaries. In this article, the effects of arsenic (As), antimony (Sb), and tin (Sn) on surface hot shortness were investigated. A series of Fe-0.3 wt pct Cu-x wt pct (As, Sb, or Sn) alloys with x content ranging from 0.06 to 0.10 wt pct was oxidized in air at 1423 K (1150 °C) for 60, 300, and 600 seconds inside the chamber of a thermogravimety analyzer (TGA) where heat is supplied through infrared radiation. Scanning electron microscopy (SEM) investigations show that (1) the presence of Sb and Sn results in severe grain boundary cracking, whereas the presence of As does not, (2) open cracks with Fe oxides were found beneath the oxide/metal interface in the Sb and Sn alloys, and (3) the oxide/metal interfaces for all As, Sb, and Sn alloys are planar. Penetration experiments of pure Cu and Cu-30 wt pct Sn liquid were also conducted in the chamber of a hot-stage confocal laser scanning microscopy (CLSM) in nonoxidizing atmosphere: (1) on the Fe-35 wt pct manganese (Mn) alloys to study the correlation between cracking and grain boundary characters, and (2) on the pure Fe substrates to exclude the bulk segregation effects of Sn on grain boundary cracking. It was found that grain boundary cracking rarely took place on low-energy grain boundaries. The results also suggest that the bulk segregation of Sn in the substrate is not necessary to promote significant grain boundary cracking, and as long as the liquid phase contains Sn, it will be highly embrittling.

Similar content being viewed by others

References

J.A.T. Jones, B. Bowman, and P.A. Lefrank: in The Making, Shaping, and Treating of Steel, Steelmaking and Refining, R.J. Fruehan, ed., AISE Steel Foundation, Pittsburgh, PA, 1998, pp. 525–660.

U.S. Geological Survey, Mineral Commodity Studies, 2010, U.S. Department of Interior-U.S. Geological Survey, Washington, DC, p. 80.

US Department of Energy Office of Industrial Technologies, Energy and Environmental Profile of the U.S. Iron and Steel Industry. 2000, Energetics Inc., Columbia, MD, pp. 10–16.

A. Nicholson and J.D. Murray: J. Iron Steel Inst., 1965, vol. 203, pp. 1007-18.

D.A. Melford: Philos. Trans. R. Soc. Lond., Ser. A, Math. Phys. Eng. Sci., 1980, vol. 295, no. 1413, pp. 89-103.

J.K.S. Tee and D.J. Fray: Ironmaking Steelmaking, 2006, vol. 33, no. 1, pp. 19-23.

B. Yalamanchili, P.M. Power, and J.B. Nelson: Wire J. Int., 1999, vol. 32, no. 5, pp. 100-06.

K. Noro, M. Takeuchi, and Y. Mizukami: ISIJ Int., 1997, vol. 37, no. 3, pp. 198-206.

W.J.M. Salter: J. Iron Steel Inst., 1966, vol. 204, pp. 478-88.

T.B. Massalski: in Binary Alloy Phase Diagram, T.B. Massalski and H. Okamoto, eds., vol. 2, ASM International, Materials Park, OH, 1990.

B.A. Webler, L. Yin, and S. Seetharaman: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 725-37.

L. Yin, S. Balaji, and S. Sridhar. Metall. Mater. Trans. B, 2010, vol. 41B, pp. 598-611.

T. Fukagawa and H. Fujikawa: Oxid. Met., 1999, vol. 52, nos. 3-4, pp. 177-94.

L.Yin and S. Sridhar: Metall. Mater. Trans. B, 2010, vol. 41B, pp. 1095-1107.

B.J. Schulz and C.J. McMahon: American Society for Testing and Materials Special Technical Publications, 1972, vol. 499, pp. 104-35.

R.H. Jones, D.R. Baer, L.A. Charlot, and M.T. Thomas: Metall. Trans. A, 1988, vol. 19A, pp. 2005-11.

M.P. Seah and E.D. Hondros: P. Roy. Soc. Lond. A Mat., 1973, vol. 335 (1601), pp. 191–212.

C.J. McMahon: American Society for Testing and Materials Special Technical Publications, vol. 407, ASTM, West Conshohocken, PA, 1968, pp. 127–67.

M.P. Seah: Acta Metall., 1980, vol. 28, no. 7, pp. 955-62.

Materials Preparation Center: Ames Laboratory, US Doe Basic Energy Sciences, www.mpc.ameslab.gov .

K. Sachs and C.W. Tuck: Proc. Conf. Reheating for Hot Working, Iron and Steel Institute, Pittsburgh, PA, 1968.

H. Abuluwefa, R.I.L. Guthrie, and F. Ajersch: Oxid. Met., 1996, vol. 46, no. 5-6, pp. 423-40.

A.P. Sutton and R.W. Balluffi: Acta Metall., 1987, vol. 35, no. 9, pp. 2177-201.

M. Takashima, P. Wynblatt, and B.L. Adams: Interface Sci., 2000, vol. 8, no. 4, pp. 351-61.

H. Ohtani, H. Suda, and K. Ishida: ISIJ Int., 1997, vol. 37, no. 3, pp. 207-16.

D.G. Mendoza, M. Hino, and K. Itagaki: J. Min. Mater. Process. Inst. Japan, 2002, vol. 118, pp. 197-201.

C.J. Smithells: in Smithells Metals Reference Book, 8th ed., W.F. Gale and T.C. Totemeier, eds., Elsevier Butterworth-Heinemann, Atlanta, GA, 2004, pp. 13–22.

A. Lisak and K. Fitzner: J. Phase Equil., 1994, vol. 15, no. 2, pp. 151-54.

K. Itagaki, D.G. Mendoza, L. Voisin, and M. Hino: Monatsh. Chem., 2005, vol. 136, pp. 1847-52.

D.E. Coates and J.S. Kirkaldy: J. Cryst. Growth, 1968, vol. 3, no. 4, pp. 549-54.

N. Birks, G.H. Meier, and F.S. Pettit: High-Temperature Oxidation of Metals, 2nd ed. Cambridge University Press, New York, NY, 2006, pp. 64-67.

S. Pötschke and A.R. Buchner: Steel Res. Int., 2006, vol. 77, no. 6, pp. 416-22.

U. Choudary, J. Serkin, and G. Belton: Metall. Trans. B, 1975, vol. 6B, pp. 399-403.

M. Arita, M. Ohyama, K.S. Goto, and M. Someno: Z. Metallkd., 1981, vol. 72, no. 4, pp. 244-50.

M. Ohno and K. Yoh: J. Cryst. Growth, 2008, vol. 310, no. 11, pp. 2751-59.

B.Y. Pei, B. Björkman, B. Sundman, and B. Jansson: CALPHAD, 1995, vol. 19, no. 1, pp. 1-15.

M. Arita, M. Tanaka, K.S. Goto, and M. Someno: Metall. Trans. A, 1981, vol. 12A, pp. 497-504.

R. Hultgren, P.D. Desai, D.T. Hawkins, M. Gleiser, K.K. Kelley: Selected Values of the Thermodynamic Properties of Elements and Selected Values of the Thermodynamic Properties of Binary Alloys, ASM, Materials Park, OH, 1973.

M. Guttmann: Philos. Trans. R. Soc. Lond., Ser. A, Math. Phys. Eng. Sci., 1980, vol. 295, no. 1413, pp. 169-96.

P. Lemblé, A. Pineau, J.L. Castagne, P. Dumoulin, and M. Guttmann: Met. Sci., 1979, vol. 13, pp. 496-502.

N. Imai, N. Komatsubara, and K. Kunishige: ISIJ Int., 1997, vol. 37, no. 3, pp. 217-23.

M.P. Seah: Surf. Sci., 1975, vol. 53, pp. 168-212.

N. Imai, N. Komatsubara, and K. Kunishige: ISIJ Int., 1997, vol. 37, no. 3, pp. 224-31.

B.A. Webler and S. Sridhar: ISIJ Int., 2007, vol. 47, no. 9, pp. 1245-54.

Acknowledgment

Financial support from the Center for Iron and Steelmaking Research (CISR) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 16, 2011

Rights and permissions

About this article

Cite this article

Yin, L., Sridhar, S. Effects of Residual Elements Arsenic, Antimony, and Tin on Surface Hot Shortness. Metall Mater Trans B 42, 1031–1043 (2011). https://doi.org/10.1007/s11663-011-9528-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9528-z