Abstract

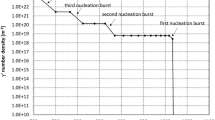

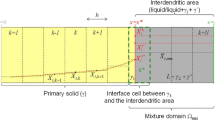

The evolution of the strengthening precipitate in a precipitation-hardening alloy, such as the gamma prime (γ′) phase in Ni-base superalloys, during heat treating and welding can affect the resultant mechanical properties significantly. Computational kinetics simulation can be a useful tool for understanding and controlling of such evolution. The present study was conducted to simulate the γ′ precipitation and dissolution during aging and welding of the recently developed Ni-base superalloy 718plus using the PanPrecipitation module of the Pandat software along with available thermodynamic and kinetic databases. The purpose was to demonstrate the application of such software and databases to materials processing including heat treating and welding. The variations in the volume fraction, average precipitation size, and number density of γ′ with time during aging and welding were calculated. The calculated results under aging condition agreed well with the available experimental data, while those under welding also predicted the correct trend.

Similar content being viewed by others

References

W.D. Cao, U.S. Patent 6730.254 B2, 2004.

K. R. Vishwakarma, N. L. Richards, M. C. Chaturvedi: Mater. Sci. Eng. A, 2008, vol. 480, pp. 517-28.

M. Jahazi, A. R. Mashreghi: Mater. Sci. Eng., 2002, vol.18, pp.458-62.

W.-D. Cao: in Superalloy 718, 625, 706 and Derivatives 2005, E.A. Loria, ed., TMS, 2005. pp. 165–77.

G. A. Zickler, R. Schnitzer, R. Radis, R. Hochfellner, R. Schweins, M. Stockinger and H. Leitner: Mater. Sci. Eng. A, 2009, vol. 523, pp.295-303.

L. Whitmore, H. Leitner, E. Povoden-Karadeniz, R. Radis and M. Stockinge: Mater. Sci. Eng. A, 2012, vol. 534, pp. s413-23.

R. Radis, G. A. Zickler, M. Stockinger, C. Sommitsch, and E. Kozeschnik: Mater. Sci. Forum, 2010, vols. 638-642, pp. 2712-17.

W. A. Owczarski, C. P. Sullivan: Welding Journal, 1964, vol.43, pp. 393s-99s.

B. Radhakrishnan, R. G. Thompson: Metall. Trans. A, 1993, vol. 24A, pp. 2773-85.

O. A. Idowu, O. A. Ojo, M. C. Chaturvedi: Welding Journal, 2009, vol. 88, pp.179s-87s.

Pandat, PanPrecipitation and PanEngine are trademarks of CompuTherm software. http://www.computherm.com/.

W. Cao, F. Zhang, S.-L. Chen, C. Zhang, Y. A. Chang: JOM, 2011, vol. 63, pp.29-34.

J. Langer, A. Schwartz: Physical Review A, 1980, vol. 21(3), pp. 948-58.

R. Kampmann and R. Wagner: in Decomposition of Alloys: the Early Stages, P. Haasen, ed., Pergamon Press, Oxford, 1984, pp. 91–105.

J. D. Robson: Mater. Sci. Eng., 2004, vol. 20, pp. 441-48.

E. Kozeschnik, I. Holzer, B. Sonderegger: J. Phase Equilib. Diffus., 2007, vol. 28(1), pp. 64–71.

W. Cao, S.-L. Chen, F. Zhang, K. Wu, Y. Yang, Y.A. Chang, R. Schmid-Fetzer, W.A. Oates: CALPHAD, 2009, vol. 33, pp. 328-342.

Acknowledgments

The first author gratefully acknowledges the financial support received from the Innovative Foundation of Shanghai University (SDCX2013031). This work was also supported by the National Science Foundation under Grant No. IIP-1034695 and the University of Wisconsin Foundation through the Industry/University Collaborative Research Center (I/UCRC) for Integrated Materials Joining Science for Energy Applications. All calculations were performed using the PanPrecipitation and PanEngine of Pandat TM software licensed from CompuTherm LLC, USA.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 19, 2013.

Rights and permissions

About this article

Cite this article

Wang, B., Zhang, F., Cao, W. et al. Computational Kinetics Simulation of Precipitation and Dissolution of Gamma Prime (γ′) in Heat Treating and Welding of 718plus Superalloy. Metall Mater Trans A 46, 115–122 (2015). https://doi.org/10.1007/s11661-014-2617-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2617-2