Abstract

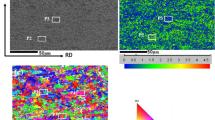

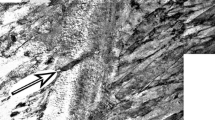

Morphological data obtained from two-dimensional (2D) and three-dimensional (3D) transmission electron microscopy (TEM) observations were compared to assess the effects of TEM projection errors for submicron-size precipitates. The microstructure consisted of M23C6 carbides in a 9 pct Cr-Mo-V heat resistant steel before and after exposure to creep conditions. Measurements obtained from about 800 carbides demonstrate that particle size and spacing estimates made from 2D observations overestimate the more accurate values obtained from 3D reconstructions. The 3D analysis also revealed the M23C6 precipitates lengthen anisotropically along lath boundary planes, suggesting that coarsening during the early stage of creep in this alloy system is governed by grain boundary diffusion.

Similar content being viewed by others

References

D. Rojas, J. Garcia, O. Prat, G. Sauthoff and A. R. Kaysser-Pyzalla, Materials Science and Engineering: A 2011, vol. 528, pp. 5164-5176.

Y. Wang, K. H. Mayer, A. Scholz, C. Berger, H. Chilukuru, K. Durst and W. Blum, Mat Sci Eng a-Struct 2009, vol. 510-11, pp. 180-184.

D. Rojas, J. Garcia, O. Prat, C. Carrasco, G. Sauthoff and A. R. Kaysser-Pyzalla, Materials Science and Engineering: A 2010, vol. 527, pp. 3864-3876.

F. Abe: in Advanced Steels, Y. Weng, D. Han, and G. Yong, ed., Springer, Metallurgical Industry Press, Berlin, 2011, pp. 409–422.

V. Dudko, A. Belyakov, D. Molodov, and R. Kaibyshev: Metall. Mater. Trans. A, 2013, vol. 44, pp. 162–172.

P. J. Ennis, A. ZielinskaLipiec, O. Wachter and A. CzyrskaFilemonowicz, Acta Materialia 1997, vol. 45, pp. 4901-4907.

A. Kipelova, R. Kaibyshev, A. Belyakov and D. Molodov, Mat Sci Eng a-Struct 2011, vol. 528, pp. 1280-1286.

F. Abe, Mat Sci Eng a-Struct 2004, vol. 387, pp. 565-569.

F. Abe, T. Horiuchi, M. Taneike and K. Sawada, Mat Sci Eng a-Struct 2004, vol. 378, pp. 299-303.

H.G. Armaki, R. Chen, K. Maruyama, and M. Igarashi, Metall. Mater. Trans. A 2011, vol. 42, pp. 3084–94.

Fujio Abe, Science and Technology of Advanced Materials 2008, vol. 9, p. 013002.

K. Kaneko, S. Matsumura, A. Sadakata, K. Fujita, W. J. Moon, S. Ozaki, N. Nishimura and Y. Tomokiyo, Mat Sci Eng a-Struct 2004, vol. 374, pp. 82-89.

H. Friedrich, C.J. Gommes, K. Overgaag, J.D. Meeldijk, W.H. Evers, B. de Nijs, M.P. Boneschanscher, P.E. de Jongh, A.J. Verkleij, K.P. de Jong, A. van Blaaderen, and D. Vanmaekelbergh, Nano Lett 2009, vol. 9, pp. 2719-2724.

Niven Monsegue, Xin Jin, Takuya Echigo, Ge Wang and Mitsuhiro Murayama, Microsc Microanal 2012, vol. 18, pp. 1362-1367.

C. J. Gommes, K. de Jong, J. P. Pirard and S. Blacher, Langmuir 2005, vol. 21, pp. 12378-12385.

P.D. Jablonski, C.J. Cowen, J.A. Hawk, G.R. Holcomb: in 25th Annual Fossil Energy Materials Conference, 2011, April 26–28, Portland, OR.

J. C. Gonzalez, J. C. Hernandez, M. Lopez-Haro, E. del Rio, J. J. Delgado, A. B. Hungria, S. Trasobares, S. Bernal, P. A. Midgley and J. J. Calvino, Angew Chem Int Edit 2009, vol. 48, pp. 5313-5315.

I. M. Lifshitz and V. V. Slyozov, Journal of Physics and Chemistry of Solids 1961, vol. 19, pp. 35-50.

O. Prat, J. Garcia, D. Rojas, C. Carrasco and A. R. Kaysser-Pyzalla, Materials Science and Engineering: A 2010, vol. 527, pp. 5976-5983.

A. Gustafson and M. Hattestrand, Mat Sci Eng a-Struct 2002, vol. 333, pp. 279-286.

Yoshikuni Kadoya, BrianF Dyson and Malcolm McLean, Metallurgical and Materials Transactions A 2002, vol. 33, pp. 2549-2557.

K. Maruyama, K. Sawada and J. Koike, Isij Int 2001, vol. 41, pp. 641-653.

Alla Kipelova, Marina Odnobokova, Andrey Belyakov and Rustam Kaibyshev, Metallurgical and Materials Transactions A 2013, vol. 44, pp. 1-7.

This work was funded as part of the National Energy Technology Laboratory’s Regional University Alliance (NETL-RUA), a collaborative initiative of the NETL, this technical effort was performed under the RES contract. The U.S. Department of Energy (DE-FG02-06ER15786) provided financial support for instrumentation. Support was also provided by the Nanoscale Characterization and Fabrication Laboratory of the Institute of Critical Technology and Applied Sciences, Virginia Tech.

This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 28, 2013.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (MP4 6542 kb)

Rights and permissions

About this article

Cite this article

Monsegue, N., Reynolds, W.T., Hawk, J.A. et al. How TEM Projection Artifacts Distort Microstructure Measurements: A Case Study in a 9 pct Cr-Mo-V Steel. Metall Mater Trans A 45, 3708–3713 (2014). https://doi.org/10.1007/s11661-014-2331-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2331-0