Abstract

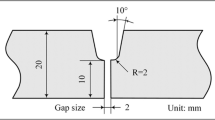

The microstructures and mechanical properties of laser penetration welding joints with/without Ni-foil in an overlap steel-on-aluminum configuration were investigated. The interfacial structure between fusion zone and aluminum alloy without Ni-foil consists of FeAl/FeAl3. After the Ni-foil is added, the interfacial structure transforms into Ni1.1Al0.9/FeAl3, and the molten pool of aluminum alloy is expanded, which leads to the formation of the NiAl3 between Ni-foil and the molten pool. A banded structure composed of β(Fe, Ni)Al appears whether the joints are made with/without Ni-foil over the reaction zone. It was found that the Ni-foil enhanced tensile property of the joint, expanded usable processing parameters, and decreased microhardness of the intermetallic compounds. The enhancement of mechanical properties is attributed to the improvement of the toughness of the joint made by Ni-foil.

Similar content being viewed by others

References

L.Q. Li, C.W. Tan, Y.B. Chen, W. Guo, and X.B. Hu: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 4740–54.

D.Q. Wang, Z.Y. Shi and R.B. Qi: Scripta Mater., 2007, vol. 56, pp. 369–72.

T. Yokoyama: Mater. Sci. Technol., 2003, vol. 19, pp. 1418–26.

B. Aizawa, M. Kashani and K. Okagawa: Weld. J. 2007, (5), pp. 119–24.

K.J. Lee, S. Kumai, T. Arai and T. Aizawa: Mater. Sci. Eng. A, 2007, vol. 471, pp. 95-101.

Y.C. Chen and K. Nakata: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1985–92.

K. Kimapong and T. Watanabe: Weld. J., 2004, (10), pp. 277–82.

M. Roulin, J.W. Luster, G. Karadeniz and A. Mortensen: Weld. J., 1999, (5), pp. 151–5.

H.T. Zhang, J.C. Feng, P. He and H. Hackl: Mater. Charact., 2007, vol. 58, 588–92.

J.L. Song, S.B. Lin, C.L. Yang, G.C. Ma and H. Liu: Mater. Sci. Eng. A, 2009, vol. 509, pp. 31–40.

H. Laukant, C. Wallmann and M. Muller: Sci. Technol. Weld. Joining, 2005, vol. 10, pp. 219–26.

A. Mathieu, S. Pontevicci, J. Viala, E. Cicala, S. Mattei, and D. Grevey: Mater. Sci. Eng. A, 2006, vol. 435–436, pp. 19–28.

G. Sierra, P. Peyre, F. Deschaux-Beaume, D. Stuart and G. Fras : Mater. Sci. Eng. A, 2007, vol. 447, pp. 197–208.

M.J. Torkamany, S. Tahamtan and J. Sabbaghzadeh: Mater. Des., 2010, vol. 31, pp. 458–65.

Y. Shi, H. Zhang, W. Takehiro and J. Tang: Opt. Laser Eng., 2010, vol. 48, 732–36.

H.C. Chen, A.J. Pinkerton, L.Li, Z. Liu and A.T. Mistry: Mater. Des., 2011, vol. 32, pp. 495–504.

L.M. Liu and X.D. Qi: J. Mater. Sci., 2009, vol. 44, pp. 5725–31.

S.H. Chen, J.H. Huang, K. Ma, H. Zhang and X.K. Zhao: Mater. Lett., 2012, vol. 79, pp. 296–99.

F. Rosalbino, G. Scavino and M. Actis Grande. J. Electroanal. Chem., 2013, vol. 694, pp. 114–21.

Materials Science International Team MSIT®: in Light Metal Systems Part 2, vol. 11A2, G. Effenberg and S. Ilyenko, eds., Springer, New York, NY, pp. 329–58.

U.R. Kattner and B.P. Burton: in Al-Fe (Aluminum-Iron), Phase Diagrams of Binary Iron Alloys, H. Okamoto, ed., ASM International, Materials Park, OH, 1993, p. 12.

K. Yoshimi, S. Hanada and M.H. Yoo: Intermetallics, 1996, vol. 4, pp. 159–68.

R.S. Sundar and S.C. Deevi: Mater. Sci. Eng. A, 2003, vol. 357, pp. 124–33.

A. Matsunawa, J.D. Kim, N. Seto, M. Mizutani and S. Katayama: J. Laser Appl., 1998, vol. 10, pp. 247–54.

S. Katayama, Y. Kobayashi, M. Mizutani and A. Matsunawa: J. Laser Appl., 2001, vol. 13, pp. 187–92.

I. Eriksson, J. Powell and A.F.H. Kaplan: Sci. Technol. Weld. Joining, 2011, vol. 16, pp. 636–41.

Y. Yang and J.D. Hu: Opt. Laser. Technol., 2011, vol. 43, pp. 138–42.

C.T. Liu, E.H. Lee and C.G. Mckamey: Scripta Metall., 1989, vol. 23, pp. 875–80.

S. Guha, P.R. Munroe and I. Baker: Mater. Sci. Eng. A, 1991, vol. 131, pp. 27–37.

Acknowledgments

The authors appreciate the financial support from the National Natural Science Foundation of China (No. 51004009) and the Fundamental Research Funds for the Central Universities (FRF-TP-12-044A).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 1, 2013.

Rights and permissions

About this article

Cite this article

Chen, S., Huang, J., Ma, K. et al. Microstructures and Mechanical Properties of Laser Penetration Welding Joint With/Without Ni-Foil in an Overlap Steel-on-Aluminum Configuration. Metall Mater Trans A 45, 3064–3073 (2014). https://doi.org/10.1007/s11661-014-2241-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2241-1