Abstract

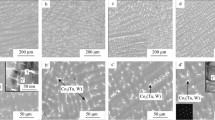

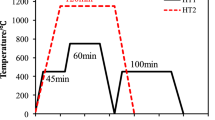

The grain boundary character distribution and the relative grain boundary energy of 100 ppm Ca-doped yttria were measured before and after a previously identified grain boundary complexion transition. The grain boundary character distribution of samples exhibiting normal grain growth (before the complexion transition) favored {111} planes, whereas those exhibiting abnormal grain growth (after the complexion transition) favored {001} planes. Additionally, the relative grain boundary-to-surface energy ratios in the sample exhibiting abnormal grain growth were 33 pct lower than in the sample exhibiting normal grain growth. The results also indicate that the complexion transition increased the anisotropy of the grain boundary energy, and this may be responsible for the increase in the anisotropy of the grain boundary character distribution.

Similar content being viewed by others

References

L. Borovkova, E. Lukin, D. Poluboyarinov, and E. Sapozhnikova: Refract. Ind. Ceram., 1970, vol. 11, pp. 717–22.

L.B. Borovkova, E.S. Lukin, and D.N. Poluboyarinov: Refract. Ind. Ceram., 1972, vol. 13, pp. 595–600.

P.L. Chen and I.W. Chen: J. Am. Ceram. Soc., 1996, vol. 79, pp. 1801–09.

P. Duran, J. Tartaj, and C. Moure: Ceram. Int., 2002, vol. 28, pp. 791–803.

P.J. Jorgensen and R.C. Anderson: J. Am. Ceram. Soc., 1967, vol. 50, pp. 553–58.

S.L. Ma and M.P. Harmer: J. Am. Ceram. Soc., 2011, vol. 94, pp. 651–55.

Y. Tsukuda: Am. Ceram. Soc. Bull., 1983, vol. 62, pp. 510–12.

A. Brenier and G. Boulon: J. Alloys Compd., 2001, vol. 323, pp. 210–13.

C. Greskovich and J.P. Chernoch: J. Appl. Phys., 1974, vol. 45, pp. 4495–4502.

J.R. Lu, K. Takaichi, T. Uematsu, A. Shirakawa, M. Musha, K. Ueda, H. Yagi, T. Yanagitani, and A.A. Kaminskii: Jpn. J. Appl. Phys. Part 2-Lett., 2002, vol. 41, pp. L1373–75.

P. Hogan, T. Stefanik, C. Willingham, and R. Gentilman: The 10 th DoD Electromagnetic Windows Symp., Norfolk, VA, 2004.

G.C. Wei, M.R. Pasucci, E.A. Trichett, C. Brecher, and W.H. Rhodes: Ceramics and Inorganic Crystals for Optics, Electro-Optics, and Nonlinear Conversion, San Diego, CA, 1988, pp. 5–13.

K.A. Wickershsheim and R.A. Lefever: J. Opt. Soc. Am., 1961, vol. 51, pp. 1147–48.

J.E. Burke and D. Turnbull: Progr. Met. Phys., 1952, vol. 3, pp. 220–92.

R.L. Coble: J. Appl. Phys., 1961, vol. 32, pp. 793–99.

S.J. Dillon, M.P. Harmer, and J. Luo: JOM, 2009, vol. 61, pp. 38–44.

S.J. Dillon, M. Tang, W.C. Carter, and M.P. Harmer: Acta Mater., 2007, vol. 55, pp. 6208–18.

M.P. Harmer: J. Am. Ceram. Soc., 2010, vol. 93, pp. 301–17.

M.P. Harmer: Science, 2011, vol. 332, pp. 182–83.

M. Tang, W.C. Carter, and R.M. Cannon: Phys. Rev. B, 2006, vol. 73, p. 14.

M. Tang, W.C. Carter, and R.M. Cannon: Phys. Rev. Lett., 2006, vol. 97, p. 4.

M. Baram, D. Chatain, and W.D. Kaplan, Science, 2011, vol. 332, pp. 206–09.

J. Luo, H.K. Cheng, K.M. Asl, C.J. Kiely, and M.P. Harmer: Science, 2011, vol. 333, pp. 1730–33.

S.J. Dillon and M.P. Harmer: Acta Mater., 2007, vol. 55, pp. 5247–54.

S.J. Dillon, M.P. Harmer, and G.S. Rohrer: J. Am. Ceram. Soc., 2010, vol. 93, pp. 1796–1802.

S.J. Dillon, H. Miller, M.P. Harmer, and G.S. Rohrer: Int. J. Mater. Res., 2010, vol. 101, pp. 50–56.

S. Ma. Ph.D. Dissertation, Lehigh University, Bethleham, PA, 2010.

G.S. Rohrer: J. Am. Ceram. Soc., 2011, vol. 94, pp. 633–46.

G.S. Rohrer: J. Mater. Sci., 2011, vol. 46, pp. 5881–95.

G.S. Rohrer, D.M. Saylor, B. El Dasher, B.L. Adams, A.D. Rollett, and P. Wynblatt: Z. Fur Metallkunde, 2004, vol. 95, pp. 197–214.

D.M. Saylor, B.S. El-Dasher, B.L. Adams, and G.S. Rohrer: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 1981–89.

D.M. Saylor and G.S. Rohrer: J. Am. Ceram. Soc., 2002, vol. 85, pp. 2799–2804.

W.W. Mullins: J. Appl. Phys., 1957, vol. 28, pp. 333–39.

S.J. Dillon, M.P. Harmer, and G.S. Rohrer: Acta Mater., 2010, vol. 58, pp. 5097–5108.

C.A. Handwerker, J.M. Dynys, R.M. Cannon, and R.L. Coble: J. Am. Ceram. Soc., 1990, vol. 73, pp. 1371–77.

D.M. Saylor, A. Morawiec, B.L. Adams, and G.S. Rohrer: Interface Sci., 2000, vol. 8, pp. 131–40.

D.M. Saylor and G.S. Rohrer: J. Am. Ceram. Soc., 1999, vol. 82, pp. 1529–36.

G.S. Rohrer: http://mimp.materials.cmu.edu/~gr20/stereology/100601_stereo.zip. 2011.

Gwyddion, http://gwyddion.net/resources.php. 2011.

S.J. Dillon and G.S. Rohrer: J. Am. Ceram. Soc., 2009, vol. 92, pp. 1580–85.

F. Papillon, G.S. Rohrer, and P. Wynblatt: J. Am. Ceram. Soc., 2009, vol. 92, pp. 3044–51.

S.J. Dillon and M.P. Harmer: J. Eur. Ceram. Soc., 2008, vol. 28, pp. 1485–93.

Acknowledgments

G.R. and S.B. acknowledge MRSEC program of the National Science Foundation under Award Number DMR-0520425. W.L. acknowledges the National Science Foundation Research Experience for Undergraduates Site grant DMR-1005076. M.P.H. and S.M. gratefully acknowledge the financial support from the U.S. DOE Office of Basic Energy Science grant in the Electron and Scanning Probe Microscopies Program (Grant No. DE-FG02-08ER46548) managed by Dr. Jane G. Zhu.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 11, 2012.

Rights and permissions

About this article

Cite this article

Bojarski, S.A., Ma, S., Lenthe, W. et al. Changes in the Grain Boundary Character and Energy Distributions Resulting from a Complexion Transition in Ca-Doped Yttria. Metall Mater Trans A 43, 3532–3538 (2012). https://doi.org/10.1007/s11661-012-1172-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1172-y