Abstract

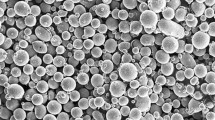

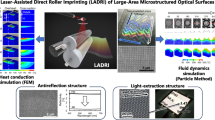

The thermal behavior during laser-engineered net shaping (LENS) processing was numerically simulated using the alternate direction explicit finite difference method in Part I of this work. In this article, Part II, the numerical simulation results were compared to experimental results obtained with LENS-deposited 316L stainless steel. In particular, the cooling rate that is present during LENS deposition was established on the basis of dendrite arm spacing (DAS) measurements with and without a melt pool sensor (MPS) and a Z-height control (ZHC) subsystem. The microstructure of the deposited materials was characterized and analyzed, and the corresponding microhardness was measured as a function of distance from the substrate. The influence of thermal history on microstructure evolution was analyzed and discussed based on both modeling and experimental results. The results discussed in this article suggest relatively good agreement between experiments and modeling.

Similar content being viewed by others

Notes

LENS is a trademark of Sandia National Laboratories, and is commercialized by Optomec, Inc., Albuquerque, NM.

PHILIPS is a trademark of Philips Electronic Instruments Corp., Mahwah, NJ.

References

B. Zheng, Y. Zhou, J.E. Smugeresky, J.M. Schoenung, and E.J. Lavernia: Metall. Mater. Trans. A, 2008, vol. 39A, DOI: 10.1007/s11661-008-9557-7.

S.A. David, J.M. Vitek, T.L. Hebble: Weld. J., 1987, vol. 66 (10), pp. 289–300

J.W. Elmer, S.M. Allen, T.W. Eager: Metall. Mater. Trans. A, 1989, vol. 20A, pp. 2117–31

W. Hofmeister, M. Griffith, M. Ensz, J. Smugeresky: JOM, 2001, vol. 53, pp. 30–34

J.E. Smugeresky, B. Zheng, Y. Zhou, and E.J. Lavernia: TMS’06, San Antonio, TX, Mar. 12–16, 2006

B. Zheng, Y. Zhou, J.E. Smugeresky, and E.J. Lavernia: Proc. Powder Metall., 2006, pp. 81–94

I.C. Stone, P. Tsakiropoulos: Int. J. Rapid Solidification, 1992, vol. 7, pp. 177–90

E.J. Lavernia: Ph.D. Dissertation, MIT, Cambridge, MA, 1986, p. 58.

C.H. Cáceres, C.J. Davidson, J.R. Griffiths, C.L. Newton: Mater. Sci. Eng. A, 2002, vol. 325, pp. 344–55

C. Labrecque, R. Angers, R. Tremblay, D. Dubé: Can. Metall. Q., 1997, vol. 36, pp. 169–75

D. Dube, A. Couture, Y. Carbonneau, M. Fiset, R. Angers, R. Tremblay: Int. J. Cast Met. Res., 1998, vol. 11, pp. 139–44

I.C. Stone, P. Tsakiropoulos: Int. J. Rapid Solidification, 1992, vol. 7, pp. 177–90

H. Mizukami, T. Suzuki, T. Umeda: Tetsu-to-Hagané, 1992, vol. 78, pp. 580–86

P.A. Joly, R. Mehrabian: J. Mater. Sci., 1974, vol. 9, pp. 1446–55

S. Katayama and A. Matsunawa: Proc. ICALEO, 1984, pp. 60–67

M.C. Flemings: Solidification Processing, McGraw-Hill, New York, NY, 1974, pp. 148–54

M.E. Glicksman, P.W. Voorhees: Metall. Trans. A, 1984, vol. 15A, pp. 995–1001

W. Hofmeister, M. Wert, J. Smugeresky, J.A. Philliber, M. Griffith, and M. Ensz: JOM, 1999, vol. 51, JOM-e online at http://www.tms.org/pubs/journals/JOM/9907/Hofmeister/Hofmeister-9907.html

M.L. Griffith, M.T. Ensz, J.D. Puskar, C.V. Robino, J.A. Brooks, J.A. Philliber, J.E. Smugeresky, W.H. Hofmeister: MRS Symp. Y. Proc., 2000, vol. 625, pp. 9–20

M.L. Griffith, M.E. Schlienger, L.D. Harwell, M.S. Oliver, M.D. Baldwin, M.T. Ensz, J.E. Smugeresky, M. Essien, J. Brooks, C.V. Robino, W.H. Hofmeister, M.J. Wert, D.V. Nelson: J. Mater. Design, 1999, vol. 20 (6), pp. 107–14

S.M. Kelly, S.L. Kampe: Metall. Mater. Trans. A, 2004, vol. 35A, pp.1861–67

E.J. Lavernia, J.D. Ayers, T.S. Srivatsan: Int. Mater. Rev., 1992, vol. 37, pp. 1–44

R.W. Cahn, P. Haasen: Physical Metallurgy, 3rd ed., Elsevier BV, New York, NY, 1983, p. 856

J.E. Smugeresky, B. Zheng, Y. Zhou, and E.J. Lavernia: TMS’05, San Francisco, CA, Feb. 13–17, 2005

http://www.azom.com/details.asp?ArticleID=2382#_Key_Properties

M.J. Donachie: Titanium, A Technical Guide, 2nd ed., ASM INTERNATIONAL, Metals Park, OH, 2000, pp. 13–24

E.J. Lavernia, Y. Wu: Spray Atomization and Deposition, John Wiley & Sons, Inc., New York, NY, 1996, pp. 311–14

Q. Xu, V.V. Gupta, E.J. Lavernia: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 527–39

A. Vasinonta, J.L. Beuth and R. Ong: Proc. 12th Ann. SFF Symp., Austin, TX, Aug. 2001, pp. 432–40

J.A. Brooks, C.V. Robino, T. Headley, S. Goods, R.C. Dykhuizen, and M.L. Griffith: SFF Symp., Austin, TX, Aug. 1999, p. 375

W.P. Liu, J.N. DuPont: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 1133–40

Y. Xiong, B. Zheng, J.E. Smugeresky, L. Ajdelsztajn, and J.M. Schoenung: MS&T’05, Pittsburgh, PA, Sept. 25–28, 2005

D.F. Susan, J.D. Puskar, J.A. Brooks, C.V. Robino: Mater. Characterization, 2006, vol. 57 (1), pp. 36–43

Acknowledgments

This work was supported by the National Science Foundation (Grant No. DMI-0423695) and by NASA Marshall (Contract No. NNM06AB11C). Work at Sandia National Laboratories is supported by the United States Department of Energy (Contract DE-AC04-94AL85000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 22, 2007.

Rights and permissions

About this article

Cite this article

Zheng, B., Zhou, Y., Smugeresky, J. et al. Thermal Behavior and Microstructure Evolution during Laser Deposition with Laser-Engineered Net Shaping: Part II. Experimental Investigation and Discussion. Metall Mater Trans A 39, 2237–2245 (2008). https://doi.org/10.1007/s11661-008-9566-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9566-6