Abstract

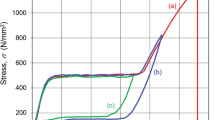

The structural fatigue of pseudoelastic Ni-Ti wires (50.9 at. pct Ni) was investigated using bending-rotation fatigue (BRF) tests, where a bent and otherwise unconstrained wire was forced to rotate at different rotational speeds. The number of cycles to failure (N f ) was measured for different bending radii and wire thicknesses (1.0, 1.2, and 1.4 mm). The wires consisted of an alloy with a 50-nm grain size, no precipitates, and some TiC inclusions. In BRF tests, the surface of the wire is subjected to tension-compression cycles, and fatigue lives can be related to the maximum tension and compression strain amplitudes (ɛ a ) in the wire surface. The resulting ɛ a -N f curves can be subdivided into three regimes. At ɛ a > 1 pct rupture occurs early (low N f ) and the fatigue-rupture characteristics were strongly dependent on ɛ a and the rotational speed (regime 1). For 0.75 pct < ɛ a < 1 pct, fatigue lives strongly increase and are characterized by a significant statistical scatter (regime 2). For ɛ a < 0.75 pct, no fatigue rupture occurs up to cycle numbers of 106 (regime 3). Using scanning electron microscopy (SEM), it was shown that surface cracks formed in regions with local stress raisers (such as inclusions and/or scratches). The growth of surface cracks during fatigue loading produced striations on the rupture surface; during final rupture, ductile voids form. The microstructural details of fatigue-damage accumulation during BRF testing are described and discussed.

Similar content being viewed by others

References

K. Otsuka and C.M. Wayman: in Shape Memory Materials, K. Otsuka and C.M. Wayman, eds., Cambridge University Press, Cambridge, United Kingdom, 1998, pp. 1–26.

L. Delaey: in Phase Transformations in Materials, Materials Science and Technology-Comprehensive Treatment-Volume 5, R.W. Cahn, P. Haasen, and E.J. Kramer, eds., VCH, Weinheim, 1991, pp. 339–404.

E. Hornbogen: in Advanced Structural and Functional Materials, W.G.J. Bunk, ed., Springer-Verlag, Heidelberg, 1991, pp. 133–63.

J. Van Humbeeck: Mater. Sci. Eng., 1999, vols. A273–A275, p. 134.

T. Duerig, A. Pelton, and D. Stöckel: Mater. Sci. Eng., 1999, vols. A273–A275, p. 149.

K. Otsuka and T. Kakeshita: MRS Bull., 2002, vol. 27, pp. 91–98.

S. Suresh: Fatigue in Materials, Cambridge University Press, Cambridge, United Kingdom, 1991.

H. Christ: Wechselverformung von Metallen, Springer-Verlag, Berlin, 1991.

K.N. Melton and O. Mercier: Acta Metall., 1979, vol. 27, pp. 137–44.

S. Miyazaki: Zairyo, 1990, vol. 39, pp. 1329–39.

Y.S. Kim and S. Miyazaki: SMST-97, Proc. Int. Conf. on Shape Memory and Superelastic Technologies, A. Pelton, D. Hodgson, R. Russel, and T. Duerig, eds., SMST, Pacific Grove, USA, 1997.

S. Miyazaki, K. Mizukoshi, T. Ueki, T. Sakuma, and Y. Liu: Mater. Sci. Eng., 1999, vols. A273—A275, pp. 658–63.

H. Tobushi, T. Nakahara, Y. Shimeno, and T. Hashimoto: Trans. ASME, 2000, vol. 122, pp. 186–91.

M. Reinoehl, D. Bradley, R. Bouthot, and J. Proft: SMST-2000, Proc. Int. Conf. on Shape Memory and Superelastic Technologies, S.M. Russel and A.R. Pelton, eds., SMST, Fremont, USA, 2001.

A. Heckmann and E. Hornbogen: SMST-SMM 2001, Proc. Int. Conf. on Shape Memory and Superelastic Technologies and Shape Memory Materials, Y.Y. Chu and L.C. Zhao, eds., Kunming, China, 2001.

E. Hornbogen: Fatigue Fract. Eng. Mater. Struct., 2002, vol. 25, pp. 785–90.

Y. Kim: Mater. Trans., 2002, vol. 43, pp. 1703–06.

A. Heckmann and E. Hornbogen: Proc. ICOMAT 2002, in Press.

A. Bracke, G. Eggeler, and D. Grönemeyer: Ruhr-Universität Bochum, Bochum, Germany, unpublished research, 2002.

J. Khalil-Allafi, A. Dlouhy, and G. Eggeler: Acta Mater., 2002, vol. 50, pp. 4255–74.

F. Kosel and B. Bundara: Mat. Sci. Forum, 2000, vols. 327–328, pp. 351–54.

T.J. Lim and D.L. McDowell: Trans. ASME, 1999, vol. 121, pp. 9–18.

M. Wagner and G. Eggeler: Ruhr-Universität Bochum, Bochum, Germany, unpublished research, 2002.

A. Yawny and M. Sade: Centro Atomico Bariloche, Argentina, unpublished research, 2002.

Metals Handbook, 9th ed., vol. 12, Fractography, ASM INTERNATIONAL, Metals Park, OH, 1987.

A.L. McKelvey and R.O. Ritchie: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 731–43.

Author information

Authors and Affiliations

Additional information

(on leave from the Centro Atomico Bariloche, Argentina)

Rights and permissions

About this article

Cite this article

Sawaguchi, T.A., Kausträter, G., Yawny, A. et al. Crack initiation and propagation in 50.9 at. pct Ni-Ti pseudoelastic shape-memory wires in bending-rotation fatigue. Metall Mater Trans A 34, 2847–2860 (2003). https://doi.org/10.1007/s11661-003-0186-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-003-0186-x