Abstract

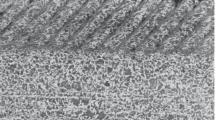

White layers (WLs) produced in hard steels by machining have been characterized using nanoindentation, optical microscopy, transmission electron microscopy (TEM), and X-ray diffraction. The WL is found to have a hardness of 12.85±0.80 GPa, which is significantly greater than that of untempered martensite produced by various heat-treatment processes. The grain size in the WL is shown to be in the submicrometer range with values ranging, typically, between 30 and 500 nm. These two characteristics of the WL distinguish it from various structures formed in steels by heat treatment. The formation of WLs is promoted by conditions of moderate to high cutting speed in conjunction with tool flank wear. Based on a consideration of the strain, stress, and temperature states associated with the formation of WLs in machining, it is hypothesized that deformation of material to very large strains is the principal factor contributing to the formation of these layers with ultrafine grained or nanocrystalline structures. The large strain deformation and elevated temperatures prevailing in the machining zone could also trigger dynamic recrystallization or cause decomposition and partial dissolution of the cementite present in the steels.

Similar content being viewed by others

References

S. Akcan, S. Shah, S.P. Moylan, P.N. Chhabra, S. Chandrasekar, and T.N. Farris: Proc. ASME MED, 1999, vol. 10, pp. 789–96.

B.J. Griffiths and D.C. Furze: ASME J. Trib., 1987, vol. 109, pp. 338–42.

J.F. Kahles and M. Field: Proc. I. Mech. E., 1967, vol. 182, pp. 31–45.

Y.C. Chou and C.J. Evans: Trans. NAMRI/SME, 1998, vol. 26, pp. 117–22.

J.Y. Wang and C.R. Liu: Ann. CIRP, 1999, vol. 48 (1), pp. 80–83.

L.P. Tarasov: Trans. ASM, 1948, vol. 40, pp. 321–46.

W.E. Littman and J. Wulff: Trans. ASM, 1955, vol. 47, pp. 692–713.

M.C. Shaw and A. Vyas: Ann. CIRP, 1994, vol. 43 (1), pp. 27–29.

K. Zum Gahr: Microstructure and Wear of Materials, Elsevier, New York, NY, 1987; see also L. Xu and N.F. Kennon: Mater. Forum, 1992, vol. 16, pp. 43–49.

G. Baumann, H.J. Fecht, and S. Liebelt: Wear, 1996, vol. 191, pp. 133–40.

L.E. Samuels: Metallographic Polishing of Metals, ASM, Metals Park, OH, 1981.

C. Zener and J.H. Hollomon: J. Appl. Phys., 1944, vol. 15, pp. 22–32.

S.A. Marian and T.A.C. Stock: Int. J. Fract. Mech., 1970, vol. 6, pp. 106–12.

J.S. Rinehart and J. Pearson: Explosive Working of Metals, Pergamon Press, New York, NY, 1963.

S. Paskal and M. Jury: Technical Report, Caterpillar Co. Peoria, IL, 1959.

M.A. Meyers: Dynamic Behavior of Materials, John Wiley, New York, NY, 1994.

E. Brinksmeier and T. Brockhoff: Proc. 2nd Int. German-French Conf. High-Speed Machining, Darmstadt, 1999; also private communication, IWT Bremen, Germany, 1999.

W. Konig, M. Klinger, and R. Link: Ann. CIRP, 1990, vol. 39 (2), pp. 417–27.

H. Tonshoff, H.G. Wobker, and D. Brandt: STLE Trans., 1995, vol. 51 (2), pp. 163–68.

W.C. Oliver and G.M. Pharr: J. Mater. Res., 1992, vol. 7 (6), pp. 1564–80.

Special Issue of Philosophical Magazine on Indentation, M.M. Chaudhri and Y. Enomoto, eds., 1996, vol. 75 (5).

Y. Ju and T.N. Farris: ASME J. Trib., 1995, vol. 118, pp. 320–28.

R. Komanduri, T.A. Schroeder, J. Hazra, B.F. von Turkovich, and D.G. Flom: ASME J. Eng. Ind., 1982, vol. 104, pp. 121–31.

M.C. Shaw: Metal Cutting Principles, Clarendon Press, Oxford, United Kingdom, 1984.

W.C. Leslie: The Physical Metallurgy of Steels, 1981, McGraw-Hill, New York, NY.

Physical Metallurgy, 3 Volume Encyclopedic Set, R.W. Cahn and P. Haasen, eds., North-Holland, Amsterdam, The Netherlands, 1996.

Y. Bai and B. Dodd: Adiabatic Shear Localization, Pergamon Press, New York, NY, 1992.

J.H. Dautzenberg and J.A.B. Van Dijck: Wear, 1982, vol. 77, pp. 217–27.

B.N.J. Persson: Sliding Friction, Springer, Berlin, NY, 1998.

S. Swaminathan and T.L. Brown: Purdue University, West Lafayette, IN, private communication, 2001.

P.W. Bridgman: Studies in Large Plastic Flow and Fracture, Harvard University Press, Cambridge, MA, 1964.

V.Y. Gertsman, R. Birringer, and R.Z. Valiev: Scripta Metall., 1994, vol. 30, pp. 229–34.

Y.V. Ivanisenko, A.V. Korznikov, I.M. Safarov, and R.Z. Valiev: Nanostr. Mater., 1995, vol. 6 (1–4), pp. 433–36.

D. Kuhlmann-Wilsdorf: Proc. 27th Leeds-Lyon Symp. Tribology, G. Dalmaz, A.A. Lubrecht, D. Dowson, and M. Priest, eds., Elsevier, Amsterdam, The Netherlands, 2000, pp. 417–28.

G. Langford and M. Cohen: Trans. ASM, 1969, vol. 62, p. 263.

G. Langford: Metall. Trans. A, 1977, vol. 8A, pp. 861–75.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Akcan, S., Shah, W.S., Moylan, S.P. et al. Formation of white layers in steels by machining and their characteristics. Metall Mater Trans A 33, 1245–1254 (2002). https://doi.org/10.1007/s11661-002-0225-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-002-0225-z