Abstract

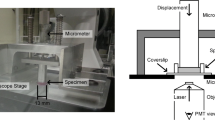

This paper presents the experimental characterization of the in-plane deformation field at any depth within a granular support medium (GSM) called Carbomer 940 using digital image correlation (DIC) and particle image velocimetry (PIV). A method was developed to produce a 2D plane of randomly shaped speckles within the GSM for DIC. Four different needle diameters and four different speeds were used as test specimens representative of those utilized for 3D printing of soft matter in the GSM. The results can be used to determine dimensional tolerances and assessing interactions between multiple injection needles and acceptable spacing. The displacements in the direction of needle motion (u) and transverse (v) were obtained. Subsequently, the magnitudes were determined as a function of distance from the needle path and time history. Results show that near the needle there is a region of yielded/fluidized material and away from the needle path the material acts like a viscoelastic solid. Permanent deformation decreases with increased distance from the path and recovery is enhanced by reversing back through the path.

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

Abbreviations

- DIC:

-

Digital image correlation

- PIV:

-

Particle image velocimetry

- GSM:

-

Granular support medium

- n :

-

Flow index

- k :

-

Consistency index

- τ0 :

-

Yield stress

- \( \dot{\upgamma} \) :

-

Strain rate

- Re :

-

Reynolds number

- Od :

-

Oldroyd number

- ρ :

-

Density

- V :

-

Velocity

- D :

-

Diameter

- (w/w):

-

Ratio of weight to weight

References

Bhattacharjee T, Zehnder SM, Rowe KG et al (2015) Writing in the granular gel medium. Sci Adv 1:e1500655–e1500655. https://doi.org/10.1126/sciadv.1500655

Curran SJ, Hayes RE, Afacan A et al (2002) Properties of Carbopol solutions as models for yield-stress fluids. J Food Sci 67:176–180. https://doi.org/10.1111/j.1365-2621.2002.tb11379.x

Kim JY, Song JY, Lee EJ, Park SK (2003) Rheological properties and microstructures of Carbopol gel network system. Colloid Polym Sci 281:614–623. https://doi.org/10.1007/s00396-002-0808-7

Boland T, Xu T, Damon B, Cui X (2006) Application of inkjet printing to tissue engineering. Biotechnol J 1:910–917. https://doi.org/10.1002/biot.200600081

Leblanc KJ, Niemi SR, Bennett AI et al (2016) Stability of high speed 3D printing in liquid-like solids. ACS Biomater Sci Eng 2:1796–1799. https://doi.org/10.1021/acsbiomaterials.6b00184

Miller JS (2014) The billion cell construct: will three-dimensional printing get us there? PLoS Biol 12:1–9. https://doi.org/10.1371/journal.pbio.1001882

Muth JT, Vogt DM, Truby RL et al (2014) Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv Mater 26:6307–6312. https://doi.org/10.1002/adma.201400334

Nishiyama Y, Nakamura M, Henmi C et al (2009) Development of a three-dimensional bioprinter: construction of cell supporting structures using hydrogel and state-of-the-art inkjet technology. J Biomech Eng 131:35001. https://doi.org/10.1115/1.3002759

Wu W, Deconinck A, Lewis JA (2011) Omnidirectional printing of 3D microvascular networks. Adv Mater 23:178–183. https://doi.org/10.1002/adma.201004625

Atapattu DD, Chhabra RP, Uhlherr PHT (1995) Creeping sphere motion in Herschel-Bulkley fluids: flow field and drag. J Nonnewton Fluid Mech 59:245–265. https://doi.org/10.1016/0377-0257(95)01373-4

Deglo De Besses B, Magnin A, Jay P (2003) Viscoplastic flow around a cylinder in an infinite medium. J Nonnewton Fluid Mech 115:27–49. https://doi.org/10.1016/S0377-0257(03)00169-1

Holenberg Y, Lavrenteva OM, Liberzon A et al (2013) PTV and PIV study of the motion of viscous drops in yield stress material. J Nonnewton Fluid Mech 193:129–143. https://doi.org/10.1016/j.jnnfm.2012.09.013

Holenberg Y, Lavrenteva OM, Shavit U, Nir A (2012) Particle tracking velocimetry and particle image velocimetry study of the slow motion of rough and smooth solid spheres in a yield-stress fluid. Phys Rev E - Stat Nonlinear, Soft Matter Phys 86:1–6. https://doi.org/10.1103/PhysRevE.86.066301

Merkak O, Jossic L, Magnin A (2006) Spheres and interactions between spheres moving at very low velocities in a yield stress fluid. J Nonnewton Fluid Mech 133:99–108. https://doi.org/10.1016/j.jnnfm.2005.10.012

Mossaz S, Jay P, Magnin A (2012) Non-recirculating and recirculating inertial flows of a viscoplastic fluid around a cylinder. J Nonnewton Fluid Mech 177–178:64–75. https://doi.org/10.1016/j.jnnfm.2012.04.008

Mossaz S, Jay P, Magnin A (2012) Experimental study of stationary inertial flows of a yield-stress fluid around a cylinder. J Nonnewton Fluid Mech 189–190:40–52. https://doi.org/10.1016/j.jnnfm.2012.10.001

Putz AMV, Burghelea TI, Frigaard IA, Martinez DM (2008) Settling of an isolated spherical particle in a yield stress shear thinning fluid. Phys Fluids. https://doi.org/10.1063/1.2883937

Tokpavi DL, Jay P, Magnin A, Jossic L (2009) Experimental study of the very slow flow of a yield stress fluid around a circular cylinder. J Nonnewton Fluid Mech 164:35–44. https://doi.org/10.1016/j.jnnfm.2009.08.002

Zisis T, Mitsoulis E (2002) Viscoplastic flow around a cylinder kept between parallel plates. J Nonnewton Fluid Mech 105:1–20. https://doi.org/10.1016/S0377-0257(02)00025-3

Tokpavi DL, Magnin A, Jay P (2008) Very slow flow of Bingham viscoplastic fluid around a circular cylinder. J Nonnewton Fluid Mech 154:65–76. https://doi.org/10.1016/j.jnnfm.2008.02.006

Keane RD, Adrian RJ (1992) Theory of cross-correlation analysis of PIV images. Appl Sci Res 49:191–215. https://doi.org/10.1007/BF00384623

Nogueira J, Lecuona A, Rodríguez PA et al (2005) Limits on the resolution of correlation PIV iterative methods. Practical implementation and design of weighting functions. Exp Fluids 39:314–321. https://doi.org/10.1007/s00348-005-1017-1

Crammond G, Boyd SW, Dulieu-Barton JM (2013) Speckle pattern quality assessment for digital image correlation. Opt Lasers Eng 51:1368–1378. https://doi.org/10.1016/j.optlaseng.2013.03.014

Mitsoulis E (2004) On creeping drag flow of a viscoplastic fluid past a circular cylinder: wall effects. Chem Eng Sci 59:789–800. https://doi.org/10.1016/j.ces.2003.09.041

Benmouffok-Benbelkacem G, Caton F, Baravian C, Skali-Lami S (2010) Non-linear viscoelasticity and temporal behavior of typical yield stress fluids: Carbopol, xanthan and ketchup. Rheol Acta 49:305–314. https://doi.org/10.1007/s00397-010-0430-4

Blaber J, Adair B, Antoniou A (2015) Ncorr: open-source 2D digital image correlation Matlab software. Exp Mech 55:1105–1122. https://doi.org/10.1007/s11340-015-0009-1

Thielicke W, Stamhuis EJ (2014) PIVlab – Towards User-friendly, Affordable and Accurate Digital Particle Image Velocimetry in MATLAB. Journal of Open Research Software. http://dx.doi.org/10.5334/jors.bl

Jop P, Mansard V, Chaudhuri P et al (2012) Microscale rheology of a soft glassy material close to yielding. Phys Rev Lett 108:1–5. https://doi.org/10.1103/PhysRevLett.108.148301

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

McGhee, A., Bennett, A., Ifju, P. et al. Full-Field Deformation Measurements in Liquid-like-Solid Granular Microgel Using Digital Image Correlation. Exp Mech 58, 137–149 (2018). https://doi.org/10.1007/s11340-017-0337-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-017-0337-4