Abstract

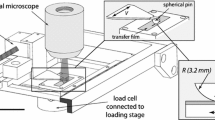

We report a hybrid wear-reducing surface by sliding steel counterfaces with pre-textured micro-pits pattern against polymeric solid lubricants. When being slid against a freshly prepared pin of the same polymer material, the hybrid surface significantly reduced wear rate of the polymer and steel counterface by up to 69% and 550% compared with the untextured unconditioned surface for the four different polymers surveyed in this study. Polymer wear generally decreased with increased iteration round of preconditioning while counterface wear was more dependent on transfer film and wear track topography. Worn counterface profilometry analysis suggested the preconditioned hybrid surface improved debris retention within the micro-pits which might mitigate wear by acting as debris reservoirs at the sliding interface and promoting transfer film formation.

Graphical abstract

Similar content being viewed by others

References

Burris, D.L., Boesl, B., Bourne, G.R., Sawyer, W.G.: Polymeric nanocomposites for tribological applications. Macromol. Mater. Eng. 292, 387–402 (2007)

Sawyer, W.G., Argibay, N., Burris, D.L., Krick, B.A.: Mechanistic studies in friction and wear of bulk materials. Annu. Rev. Mater. Res. 44, 395–427 (2014). https://doi.org/10.1146/annurev-matsci-070813-113533

Ye, J., Burris, D.L., Xie, T.: A review of transfer films and their role in ultra-low-wear sliding of polymers. Lubricants. 4, 4 (2016). https://doi.org/10.3390/lubricants4010004

Ye, J., Sun, W., Zhang, Y., Liu, X., Liu, K.: Measuring evolution of transfer film–substrate interface using low wear alumina PTFE. Tribol. Lett. (2018). https://doi.org/10.1007/s11249-018-1054-6

Wieleba, W.: The statistical correlation of the coefficient of friction and wear rate of PTFE composites with steel counterface roughness and hardness. Wear 252, 719–729 (2002). https://doi.org/10.1016/S0043-1648(02)00029-7

Franklin, S.E., de Kraker, A.: Investigation of counterface surface topography effects on the wear and transfer behaviour of a POM–20% PTFE composite. Wear 255, 766–773 (2003). https://doi.org/10.1016/S0043-1648(03)00193-5

Blanchet, T.A., Kandanur, S.S., Schadler, L.S.: Coupled effect of filler content and countersurface roughness on PTFE nanocomposite wear resistance. Tribol. Lett. 40, 11–21 (2009). https://doi.org/10.1007/s11249-009-9519-2

Laux, K.A., Schwartz, C.J.: Influence of linear reciprocating and multi-directional sliding on PEEK wear performance and transfer film formation. Wear 301, 727–734 (2013). https://doi.org/10.1016/j.wear.2012.12.004

Burris, D.L., Sawyer, W.G.: Tribological sensitivity of PTFE/alumina nanocomposites to a range of traditional surface finishes. Tribol. Trans. 48, 147–153 (2005). https://doi.org/10.1080/05698190590923842

Harris, K.L., Curry, J.F., Pitenis, A.A., Rowe, K.G., Sidebottom, M.A., Sawyer, W.G., Krick, B.A.: Wear debris mobility, aligned surface roughness, and the low wear behavior of filled polytetrafluoroethylene. Tribol. Lett. 60, 1–8 (2015). https://doi.org/10.1007/s11249-015-0581-7

Ye, J., Tao, B., Sun, W., Haidar, D.R., Alam, K.I., Liu, K., Burris, D.L.: The competing effects of counterface peaks and valleys on the wear and transfer of ultra-low wear alumina–PTFE. Tribol. Lett. 66, 12 (2018). https://doi.org/10.1007/s11249-017-0966-x

Li, J., Xiong, D., Dai, J., Huang, Z., Tyagi, R.: Effect of surface laser texture on friction properties of nickel-based composite. Tribol. Int. 43, 1193–1199 (2010). https://doi.org/10.1016/j.triboint.2009.12.044

Hu, T., Hu, L., Ding, Q.: Effective solution for the tribological problems of Ti-6Al-4V: combination of laser surface texturing and solid lubricant film. Surf. Coat. Technol. 206, 5060–5066 (2012). https://doi.org/10.1016/j.surfcoat.2012.06.014

Wu, Z., Deng, J., Zhang, H., Lian, Y., Zhao, J.: Tribological behavior of textured cemented carbide filled with solid lubricants in dry sliding with titanium alloys. Wear 292–293, 135–143 (2012). https://doi.org/10.1016/j.wear.2012.05.021

Hu, T., Zhang, Y., Hu, L.: Tribological investigation of MoS2 coatings deposited on the laser textured surface. Wear 278–279, 77–82 (2012). https://doi.org/10.1016/j.wear.2012.01.001

Li, J., Xiong, D., Zhang, Y., Zhu, H., Qin, Y., Kong, J.: Friction and wear properties of MoS2-overcoated laser surface-textured silver-containing nickel-based alloy at elevated temperatures. Tribol. Lett. 43, 221–228 (2011). https://doi.org/10.1007/s11249-011-9797-3

Basnyat, P., Luster, B., Muratore, C., Voevodin, A.A., Haasch, R., Zakeri, R., Kohli, P., Aouadi, S.M.: Surface texturing for adaptive solid lubrication. Surf. Coat. Technol. 203, 73–79 (2008). https://doi.org/10.1016/j.surfcoat.2008.07.033

Voevodin, A.A., Zabinski, J.S.: Laser surface texturing for adaptive solid lubrication. Wear 261, 1285–1292 (2006). https://doi.org/10.1016/j.wear.2006.03.013

Cho, M.: Friction and wear of a hybrid surface texturing of polyphenylene sulfide-filled micropores. Wear 346–347, 158–167 (2016). https://doi.org/10.1016/j.wear.2015.11.010

Ye, J., Zhang, H., Liu, X., Liu, K.: Low wear steel counterface texture design: a case study using micro-pits texture and alumina–PTFE nanocomposite. Tribol. Lett. 65, 165 (2017). https://doi.org/10.1007/s11249-017-0948-z

McCook, N., Hamilton, M., Burris, D., Sawyer, W.: Tribological results of PEEK nanocomposites in dry sliding against 440C in various gas environments. Wear 262, 1511–1515 (2007)

Burris, D.L., Sawyer, W.G.: Improved wear resistance in alumina-PTFE nanocomposites with irregular shaped nanoparticles. Wear 260, 915–918 (2006)

San, J., Liu, J., Zhu, B., Liu, Z., Dong, C., Zhang, Q.: Tribological properties of ion-implanted polyphenylene oxide (PPO). Wear 251, 1504–1510 (2001). https://doi.org/10.1016/S0043-1648(01)00805-5

Amstutz, H.C.: Polymers as bearing materials for total hip replacement: a friction and wear analysis. J. Biomed. Mater. Res. 3, 547–568 (1969). https://doi.org/10.1002/jbm.820030402

Krick, B.A., Pitenis, A.A., Harris, K.L., Junk, C.P., Sawyer, W.G., Brown, S.C., Rosenfeld, H.D., Kasprzak, D.J., Johnson, R.S., Chan, C.D., Blackman, G.S.: Ultralow wear fluoropolymer composites: nanoscale functionality from microscale fillers. Tribol. Int. 95, 245–255 (2016). https://doi.org/10.1016/j.triboint.2015.10.002

Song, L., Shi, G., Li, Z.: Simulation of laser drilling temperature field by using ANSYS. Acta Armamentarii 5, 879–882 (2006)

Wenyuan, G., Maocai, W., Xiaobing, Z.: Recast layer formed by laser drilling of Ni-based superalloys and progress on its control. Laser J. 24, 1–3 (2003)

Zeng, C., Tian, W., Hua, L.: A comprehensive study of thermal damage consequent to laser surface treatment. Mater. Sci. Eng. A. 564, 381–388 (2013). https://doi.org/10.1016/j.msea.2012.11.078

Haidar, D.R., Alam, K.I., Burris, D.L.: Tribological insensitivity of an ultralow-wear poly(etheretherketone)–polytetrafluoroethylene polymer blend to changes in environmental moisture. J. Phys. Chem. C 122, 5518–5524 (2018). https://doi.org/10.1021/acs.jpcc.7b12487

Burris, D.L., Sawyer, W.G.: Measurement uncertainties in wear rates. Tribol. Lett. 36, 81–87 (2009). https://doi.org/10.1007/s11249-009-9477-8

George, D., Mallery, P.: IBM SPSS statistics 23 step by step: a simple guide and reference. Routledge, New York (2016)

Ruxton, G.D., Beauchamp, G.: Time for some a priori thinking about post hoc testing. Behav. Ecol. 19, 690–693 (2008). https://doi.org/10.1093/beheco/arn020

Bahadur, S., Tabor, D.: The wear of filled polytetrafluoroethylene. Wear 98, 1–13 (1984). https://doi.org/10.1016/0043-1648(84)90213-8

Khare, H.S., Moore, A.C., Haidar, D.R., Gong, L., Ye, J., Rabolt, J.F., Burris, D.L.: Interrelated effects of temperature and environment on wear and tribochemistry of an ultralow wear PTFE composite. J. Phys. Chem. C 119, 16518–16527 (2015). https://doi.org/10.1021/acs.jpcc.5b00947

Pitenis, A.A., Ewin, J.J., Harris, K.L., Sawyer, W.G., Krick, B.A.: In vacuo tribological behavior of polytetrafluoroethylene (PTFE) and alumina nanocomposites: the importance of water for ultralow wear. Tribol. Lett. (2014). https://doi.org/10.1007/s11249-013-0256-1

Pitenis, A.A., Harris, K.L., Junk, C.P., Blackman, G.S., Sawyer, W.G., Krick, B.A.: Ultralow wear PTFE and alumina composites: it is all about tribochemistry. Tribol. Lett. (2015). https://doi.org/10.1007/s11249-014-0445-6

Wang, X.Y., Ng, G.K.L., Liu, Z., Li, L., Bradley, L.: EPMA microanalysis of recast layers produced during laser drilling of type 305 stainless steel. Thin Solid Films 453–454, 84–88 (2004). https://doi.org/10.1016/j.tsf.2003.11.158

Imran, M., Mativenga, P.T., Gholinia, A., Withers, P.J.: Assessment of surface integrity of Ni superalloy after electrical-discharge, laser and mechanical micro-drilling processes. Int. J. Adv. Manuf. Technol. 79, 1303–1311 (2015). https://doi.org/10.1007/s00170-015-6909-5

Acknowledgements

The authors gratefully acknowledge financial support from the National Natural Science Foundation of China (Grant Nos. 51875153, 51875152, and 51975174).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ye, J., Zhang, Y., Zhang, K. et al. Hybrid Wear-Reducing Micro-pits Counterface Texture Against Polymeric Solid Lubricants. Tribol Lett 68, 33 (2020). https://doi.org/10.1007/s11249-020-1271-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-020-1271-7