Abstract

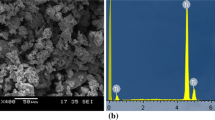

Titanium (Ti) and Ti-based alloy wear performance is often poor unless coating or lubricants are used. An alternative is to use hard phase reinforcement. Cold spray is a relatively new method to deposit composite coatings, where here we report the deposition of a Ti–TiC coating and its sliding wear behavior. Mixtures of mechanically blended Ti–TiC with various TiC content were injected into a de Laval nozzle and sprayed onto substrates. Two composite coatings and a pure Ti coating are reported here, where the as-sprayed compositions of the composites were 13.8 and 33.4 vol% TiC. Reciprocating dry sliding wear was performed using a custom-built in situ tribometer. All tests were conducted with a sliding speed of 3 mm/s and at a normal load of 0.5 N. Using a transparent sapphire hemisphere of 6.25 mm as counterface, dynamic behavior of third bodies was directly observed. It was found that adhesive transfer of Ti was the primary wear mechanism for the Ti coating, with oxidative and abrasive wear also occurring for longer sliding cycles. The superior wear resistance of the composite coatings compared to Ti was related to dual function of TiC particles, where they reinforced the Ti matrix and facilitated the formation of a stable and protective tribofilms. The tribofilms contained carbonaceous material that provided easier shear and lower friction. The formation of these tribofilms was highly dependent on the TiC particles, which contained excess carbon compared to the equilibrium composition. Higher TiC content was more effective in quickly developing and sustaining the tribofilms.

Similar content being viewed by others

References

Boyer, R.R.: An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 213, 103–114 (1996)

Dong, H., Bell, T.: Tribological behaviour of alumina sliding against Ti6Al4V in unlubricated contact. Wear 225–229, 874–884 (1999)

Chelliah, N., Kailas, S.V.: Synergy between tribo-oxidation and strain rate response on governing the dry sliding wear behavior of titanium. Wear 266, 704–712 (2009)

Qu, J., Blau, P.J., Watkins, T.R., Cavin, O.B., Kulkarni, N.S.: Friction and wear of titanium alloys sliding against metal, polymer, and ceramic counterfaces. Wear 258, 1348–1356 (2005)

Jin, L., Riahi, A.R., Farokhzadeh, K., Edrisy, A.: Investigation on interfacial adhesion of Ti–6Al–4V/nitride coatings. Surf. Coat. Technol. 260, 155–167 (2014)

Molinari, A., Straffelini, G., Tesi, B., Bacci, T.: Dry sliding wear mechanisms of the Ti6Al4V alloy. Wear 208, 105–112 (1997)

Mohanty, M., Smith, R.W.: Lightweight TiC/Ti wear-resistant coatings for lightweight structural applications. J. Therm. Spray Technol. 4, 384–394 (1995)

Candel, J.J., Amig, V., Ramos, J.A., Busquets, D.: Sliding wear resistance of TiCp reinforced titanium composite coating produced by laser cladding. Surf. Coat. Technol. 204, 3161–3166 (2010)

Wu, P., Du, H.M., Chen, X.L., Li, Z.Q., Bai, H.L., Jiang, E.Y.: Influence of WC particle behavior on the wear resistance properties of Ni–WC composite coatings. Wear 257, 142–147 (2004)

Guo, C., Zhou, J., Chen, J., Zhao, J., Yu, Y., Zhou, H.: High temperature wear resistance of laser cladding NiCrBSi and NiCrBSi/WC–Ni composite coatings. Wear 270, 492–498 (2011)

Xu, J.S., Zhang, X.C., Xuan, F.Z., Wang, Z.D., Tu, S.T.: Microstructure and sliding wear resistance of laser cladded WC/Ni composite coatings with different contents of WC particle. J. Mater. Eng. Perform. 21, 1904–1911 (2012)

Lovelock, H.L.D.V.: Powder/processing/structure relationships in WC–Co thermal spray coatings: a review of the published literature. J. Therm. Spray Technol. 7(3), 357–373 (1998)

Yuan, J., Zhu, Y., Zheng, X., Ji, H., Yang, T.: Fabrication and evaluation of atmospheric plasma spraying WC–Co–Cu–MoS2 composite coatings. J. Alloys Compd. 509, 2576–2581 (2011)

Champagne, V.K.: The Cold Spray Materials Deposition Process: Fundamentals and Applications. Woodhead, Cambridge (2007)

Alidokht, S.A., Manimunda, P., Vo, P., Yue, S., Chromik, R.R.: Cold spray deposition of a Ni-WC composite coating and its dry sliding wear behavior. Surf. Coat. Technol. 308, 424–434 (2016)

Godet, M.: The third-body approach: a mechanical view of wear. Wear 100, 437452 (1984)

Berthier, Y.: Third-body reality—consequences and use of the third-body concept to solve friction and wear problems. In: Stachowiak, G.W. (ed.) Wear—Materials, Mechanisms and Practice, pp. 291–316. Wiley, New York (2005)

Holmberg, K.: Coatings Tribology: Properties, Mechanisms, Techniques and Applications in Surface Engineering. Elsevier, Amsterdam (1994)

Chromik, R.R., Strauss, H.W., Scharf, T.W.: Materials phenomena revealed by in situ tribometry. JOM 64, 35–43 (2012)

Shockley, J.M., Strauss, H.W., Brodusch, N., Gauvin, R., Irissou, E., Legoux, J.-G.: In situ tribometry of cold-sprayed Al–Al2O3 composite coatings. Surf. Coat. Technol. 215, 350–356 (2013)

Shockley, J.M., Descartes, S., Irissou, E., Legoux, J.-G., Chromik, R.R.: Third body behavior during dry sliding of cold-sprayed Al–Al2O3 composites: in situ tribometry and microanalysis. Tribol. Lett. 54, 191–206 (2014)

Bhushan, B.: Principles and Applications of Tribology. Wiley, New York (2006)

Klinkov, S.V., Kosarev, V.F., Sova, A.A., Smurov, I.: Calculation of particle parameters for cold spraying of metal–ceramic mixtures. J. Therm. Spray Technol. 18, 944–956 (2009)

Yu, M., Li, W.-Y., Suo, X.K., Liao, H.L.: Effects of gas temperature and ceramic particle content on microstructure and microhardness of cold sprayed SiCp/Al 5056 composite coatings. Surf. Coat. Technol. 220, 102–106 (2013)

Irissou, E., Legoux, J., Arsenault, B., Moreau, C.: Investigation of Al–Al2O3 cold spray coating formation and properties. J. Therm. Spray Technol. 16, 661–668 (2007)

Grigoriev, S., Okunkova, A., Sova, A., Bertrand, P., Smurov, I.: Cold spraying: from process fundamentals towards advanced applications. Surf. Coat. Technol. 268, 77–84 (2015)

Frank, O., Zukalova, M., Laskova, B., Kürti, J., Koltai, J., Kavan, L.: Raman spectra of titanium dioxide (anatase, rutile) with identified oxygen isotopes (16, 17, 18). Phys. Chem. Chem. Phys. 14, 14567–14572 (2012)

Lohse, B.H., Calka, A., Wexler, D.: Raman spectroscopy sheds new light on TiC formation during the controlled milling of titanium and carbon. J. Alloys Compd. 434–435, 405–409 (2007)

Klein, M.V., Holy, J.A., Williams, W.S.: Raman scattering induced by carbon vacancies in TiCx. Phys. Rev. B 17, 1546–1556 (1978)

Urbonaitea, S., Halldahl, L., Svensson, G.: Raman spectroscopy studies of carbide derived carbons. Carbon 46, 1942–1947 (2008)

Ferrari, A.C., Robertson, J.: Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon. Phys. Rev B 64(7), 754141–7541413 (2001)

Chromik, R.R., Winfrey, A.L., Luning, J., Nemanich, R.J., Wahl, K.J.: Run-in behavior of nanocrystalline diamond coatings studied by in situ tribometry. Wear 265, 477–489 (2008)

Hoffman, E.E., Marks, L.D.: Graphitic carbon films across systems. Tribol. Lett. 63(3), 1–21 (2016)

Farokhzadeh, K., Edrisy, A.: Transition between mild and severe wear in titanium alloys. Tribol. Int. 94, 98–111 (2016)

Buckley, D.H.: Surface Effects in Adhesion, Friction, Wear, and Lubrication. Elsevier, Amsterdam (1981)

Dong, H., Bloyce, A., Morton, P.H., Bell, T.: Surface engineering to improve tribological performance of Ti–6Al–4V. Surf. Eng. 13, 402–406 (1997)

Jiang, J., Stott, F.H., Stack, M.M.: The role of triboparticulates in dry sliding wear. Tribol. Int. 31, 245–256 (1998)

Jiang, J., Stott, F.H., Stack, M.M.: Some frictional features associated with the sliding wear of the nickel-base alloy N80A at temperatures to 250 °C. Wear 176, 185–194 (1994)

Triantou, K.I., Pantelis, D.I., Guipont, V., Jeandin, M.: Microstructure and tribological behavior of copper and composite copper + alumina cold sprayed coatings for various alumina contents. Wear 336–337, 96–107 (2015)

Straffelini, G., Molinari, A.: Dry sliding wear of Ti–6Al–4V alloy as influenced by the counterface and sliding conditions. Wear 236, 328–338 (1999)

Alam, M.O., Haseeb, A.S.M.A.: Response of Ti–6Al–4V and Ti–24Al–11Nb alloys to dry sliding wear against hardened steel. Tribol. Int. 35, 357–362 (2002)

Mao, Y.S., Wang, L., Chen, K.M., Wang, S.Q., Cui, X.H.: Tribo-layer and its role in dry sliding wear of Ti–6Al–4V alloy. Wear 297, 1032 (2013)

Hong, H.S.: The role of atmospheres and lubricants in the oxidational wear of metals. Tribol. Int. 35, 725–729 (2002)

Hong, H., Winer, W.O.: A fundamental tribological study of Ti/Al2O3 contact in sliding wear. J. Tribol. Lett. 111, 504–509 (1989)

Bowden, F.P., Tabor, D.: The Friction and Lubrication of Solids. Oxford University Press, Oxford (2001)

Acknowledgements

The authors gratefully acknowledge the financial support from the Canadian Foundation for Innovation (CFI) Project No. 8246 for the cold spray equipment, the CFI Leader’s Opportunity Fund Project No. 13029 for the tribometer and nanoindentation equipment, and the Natural Sciences and Engineering Research Council (NSERC) Strategic Grants Program for the operational funding of this project. Thanks are also to Tekna Inc. of Sherbrooke, QC for providing spherical TiC powders. The authors acknowledge administrative support from Drs. Eric Irissou and Jean-Gabriel Legoux (the NRC) and Prof. Stephen Yue (McGill University) and technical support and helpful discussion from Dr. Phuong Vo at the McGill Aerospace Materials and Alloy Design Center (MAMADC) cold spray facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alidokht, S.A., Munagala, V.N.V. & Chromik, R.R. Role of Third Bodies in Friction and Wear of Cold-Sprayed Ti and Ti–TiC Composite Coatings. Tribol Lett 65, 114 (2017). https://doi.org/10.1007/s11249-017-0899-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-017-0899-4