Abstract

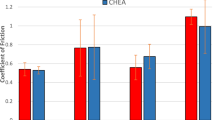

Two cold spray coatings, one pure Cu and the other a Cu–MoS2 composite coating, were studied for their tribology performance in dry air. It was demonstrated that a small amount of MoS2 (1.8 ± 0.99 wt%) could significantly decrease coefficient of friction (CoF) from around 0.7 (Cu coating) to 0.14–0.15. MoS2 patches on the wear track exhibited a lower local CoF, and the main velocity accommodation mechanism was shearing MoS2-containing debris. Even though the coating wear rates were high in the early sliding (8.61–12.8 nm/cycle in penetration depth during the first 100 cycles), slow wear (0.12–0.22 nm/cycle) over the subsequent sliding was observed. It was also found that the presence of MoS2 helped to achieve high endurance of the first steady-state CoF. The dynamics of the process, material transfer, and phase transformation were examined using scanning electron microscopy, energy-dispersive X-ray spectroscopy, and Raman spectroscopy. The MoS2 patches developed on the wear track and the counterface served as reservoirs to replenish MoS2 in the contact and became depleted with sliding. Cross-sectional microstructure revealed by electron channeling contrast imaging technique showed a layer of sliding-induced microstructure, 3–5 µm thick for the Cu–MoS2 coating, and 10–30 µm thick for the Cu coating.

Similar content being viewed by others

References

Wahl, K.J., Singer, I.L.: Quantification of a lubricant transfer process that enhances the sliding life of a MoS2 coating. Tribol. Lett. 1, 59–66 (1995)

Martin, J.M., Donnet, C., Le Mogne, T., Epicier, T.: Superlubricity of molybdenum disulphide. Phys. Rev. B 48(14), 10583–10586 (1993)

Dudder, G.J., Zhao, X., Krick, B., Sawyer, W.G., Perry, S.S.: Environmental effects on the tribology and microstructure of MoS2–Sb2O3–C films. Tribol. Lett. 42, 203–213 (2011)

Lansdown, A.R.: Tribology Series. Elsevier, Amsterdam (1999)

Dhanasekaran, S., Gnanamoorthy, R.: Dry sliding friction and wear characteristics of Fe–C–Cu alloy containing molybdenum disulphide. Mater. Des. 28, 1135–1141 (2007)

Kato, H., Takama, M., Iwai, Y., Washida, K., Sasaki, Y.: Wear and mechanical properties of sintered copper–tin composites containing graphite or molybdenum disulfide. Wear 255, 573–578 (2003)

Du, H., Sun, C., Hua, W., Wang, T., Gong, J., Jiang, X., Lee, S.W.: Structure, mechanical and sliding wear properties of WC–Co/MoS2–Ni coatings by detonation gun spray. Mater. Sci. Eng. A 445–446, 122–134 (2007)

Du, H., Sun, C., Hua, W.G., Zhang, Y.S., Han, Z., Wang, T.G., Gong, J., Lee, S.W.: Fabrication and evaluation of D-gun sprayed WC–Co coating with self-lubricating property. Tribol. Lett. 23, 261–266 (2006)

Yuan, J., Zhu, Y., Zheng, X., Ji, H., Yang, T.: Fabrication and evaluation of atmospheric plasma spraying WC–Co–Cu–MoS2 composite coatings. J. Alloys Compd. 509, 2576–2581 (2011)

Kovalchenko, A.M., Fushchich, O.I., Danyluk, S.: The tribological properties and mechanism of wear of Cu-based sintered powder materials containing molybdenum disulfide and molybdenum diselenite under unlubricated sliding against copper. Wear 290–291, 106–123 (2012)

Champagne, V.K.: The Cold Spray Materials Deposition Process: Fundamentals and Applications. Woodhead, Cambridge (2007)

Irissou, E., Jean-Gabriel, L., Anatoly, R., Bertrand, J., Christian, M.: Review on cold spray process and technology: part I-intellectual property. J. Therm. Spray Technol. 17, 495–516 (2008)

Assadi, H., Gartner, F., Stoltenhoff, T., Kreye, H.: Bonding mechanism in cold gas spraying. Acta Mater. 51, 4379–4394 (2003)

Bae, G., Kumar, S., Yoon, S., Kang, K., Na, H., Kim, H., Lee, C.: Bonding features and associated mechanisms in kinetic sprayed titanium coatings. Acta Mater. 57, 5654–5666 (2009)

Grujicic, M., Pandurangan, B., Bell, W.C., Daqaq, M., Ma, L., Seyr, N., Erdmann, M., Holzleitner, J.: A computational analysis and suitability assessment of cold-gas dynamic spraying of glass-fiber-reinforced poly-amide 6 for use in direct-adhesion polymer metal hybrid components. Appl. Surf. Sci. 254(7), 2136–2145 (2008)

Smid, I., Segall, A.E., Walia, P., Aggarwal, G., Eden, T.J., Potter, J.K.: Cold-sprayed Ni-hBN self-lubricating coatings. Tribol. Trans. 55, 599–605 (2012)

Yamada, M., Wakabayashi, J., Fukumoto, M., Kitamura, J.: Fabrication of Cu–MoS2 composite coating by cold spraying and evaluation of its property. In: Marple, B.R., Hyland, M.M., Lau, Y.-C., Li, C.-J., Lima, R.S., Montavon, G. (eds.) Proceedings of the International Thermal Spray Conference 2009, pp. 326–330 (2009)

Strauss, H.W., Chromik, R.R., Hassani, S., Klemberg-Sapieha, J.E.: In situ tribology of nanocomposite Ti–Si–C–H coatings prepared by PE-CVD. Wear 272, 133–148 (2011)

Liu, K.-K., Zhang, W., Lee, Y.-H., Lin, Y.-C., Chang, M.-T., Su, C.-Y., Chang, C.-S., Li, H., Shi, Y., Zhang, H., Lai, C.-S., Li, L.-J.: Growth of large-area and highly crystalline MoS2 thin layers on insulating substrates. Nano Lett. 12(3), 1538–1544 (2012)

Hessea, J.F., Compaan, A.: Resonance Raman studies of annealing in He-, Na-, Cd-implanted cuprous oxide. J. Appl. Phys. 50, 206–213 (1979)

Zhang, Y., Brodusch, N., Descartes, S., Chromik, R.R., Gauvin, R.: Microstructure refinement of cold-sprayed copper investigated by electron channeling contrast imaging. Microsc. Microanal. 20, 1499–1506 (2014)

Lince, J.R.: Tribology of co-sputtered nanocomposite Au/MoS2 solid lubricant films over a wide contact stress range. Tribol. Lett. 17(3), 419–428 (2007)

Stoyanov, P., Strauss, H.W., Chromik, R.R.: Scaling effects between micro- and macro-tribology for a Ti–MoS2 coating. Wear 274–275, 149–161 (2012)

Wahl, K.J., Chromik, R.R., Lee, G.Y.: Quantitative in situ measurement of transfer film thickness by a Newton’s rings method. Wear 264, 731–736 (2008)

Bowden, F.P., Tabor, D.: The Friction and Lubrication of Solids. Clarendon, Oxford (1986)

Dvorak, S.D., Wahl, K.J., Singer, I.L.: In Situ analysis of third body contributions to sliding friction of a Pb–Mo–S Coating in dry and humid air. Tribol. Lett. 28, 263–274 (2007)

Uemura, M., Okada, K., Mogami, A., Okitsu, A.: Effect of friction mechanisms on friction coefficient of MoS2 in an ultrahigh-vacuum. Lubric. Eng. 43, 937–942 (1987)

Yao, B., Han, Z., Lu, K.: Dry sliding tribological properties and subsurface structure of nanostructured copper at liquid nitrogen temperature. Wear 301, 608–614 (2013)

Rupert, T.J., Schuh, C.A.: Sliding wear of nanocrystalline Ni–W: structural evolution and the apparent breakdown of Archard scaling. Acta Mater. 58, 4137–4148 (2010)

Rupert, T.J., Gianola, D.S., Gan, Y., Hemker, K.J.: Experimental observations of stress-driven grain boundary migration. Science 326, 1686–1690 (2009)

Hamilton, G.M.: Explicit equations for the stresses beneath a sliding spherical contact. Proc. Inst. Mech. Eng. C 197, 53–59 (1983)

Rigney, D.A.: Comments on the sliding wear of metals. Tribol. Int. 30, 361–367 (1997)

Acknowledgments

The authors gratefully acknowledge the financial support from Natural Sciences and Engineering Research Council (NSERC) of Canada. They gratefully acknowledge helpful discussion with Dr. Praveena Manimunda, help from Walker Nickerson for sample preparation, and Tekna Plasma Systems Inc. for donation of the powder. The authors acknowledge administrative support from Drs. Eric Irissou and Jean-Gabriel Legoux (the NRC) and Stephen Yue (McGill University) and technical support from Mr. Jean Francois Alarie at the McGill Aerospace Materials and Alloy Design Center (MAMADC) cold spray facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Michael Shockley, J., Vo, P. et al. Tribological Behavior of a Cold-Sprayed Cu–MoS2 Composite Coating During Dry Sliding Wear. Tribol Lett 62, 9 (2016). https://doi.org/10.1007/s11249-016-0646-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-016-0646-2