Abstract

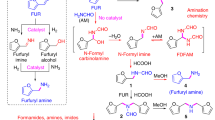

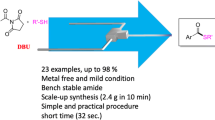

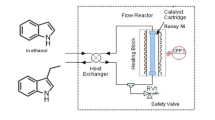

To overcome stability issues associated with the use of an aldehyde in a catalytic reductive amination reaction, a cyclic ketolactol (ω-hydroxylactone) was employed as an aldehyde surrogate to form a γ-aminoacid. The reaction proceeded most favorably over a Pt/C catalyst. The thermodynamics of each step were evaluated using density functional theory calculations, which correctly predicted the dominance of the ring-closed lactol reactant, yet suggested a preference for a ring-opened iminium intermediate upon the initial, slightly endoergic addition of amine substrate. Exoergic hydrogenation of this intermediate provided the thermodynamic driving force for the overall transformation. During development, the reaction was observed to depend significantly on the volumetric gas to liquid mass transfer coefficient (kLa) and this parameter was optimized to ensure successful scale up in a 400 L stirred tank reactor.

Similar content being viewed by others

Notes

Brief unoptimized catalyst screening suggested Pt/C provided better yield than Pt on other supports (Al2O3, graphite) or “poisoned” Pt (S, Bi) or a variety of Pd catalysts. Interestingly, select “homogeneous” Ir based catalysts were evaluated and found to exhibit an intriguing inverse dependence on ligand concentration, consistent with nanoparticle catalyzed reduction see Ref. [15].

The relative stabilities of the aminolactone and iminium forms of seven exhibit a basis set dependence. PCM-B3LYP/6-31G* total energies actually predict a reversed preference, in favor of the aminolactone species (∆E = 1.9 kcal/mol.) However, inclusion of zero-point energy and TΔS terms from the PCM-B3LYP/B3LYP/6-31G* vibrational frequencies result in an energetic preference (∆G = 1.7 kcal/mol) in favor of the iminium form, reinforced by the PCM-B3LYP/cc-PVTZ energy evaluations (Fig. 3.) The enamine tautomer (not shown) of seven is predicted to lie >10 kcal/mol on the B3LYP potential energy surface, and thus is not expected to play a significant role in this chemical transformation.

Other mixing parameters have been compared for the reactors described in this work, including Reynold’s number, tip speed and energy dissipation per reaction volume following literature methodology. While these parameters are critical to understanding scale-up of a variety of processes, kLa was the most relevant parameter to consider in this process.

References

Augustine RL (1996) Heterogeneous Catalysis for the Synthetic Chemist. Marcel Dekker, New York

Nishimura S (2001) Handbook of Heterogeneous Catalytic Hydrogenation for Organic Synthesis. Wiley, New York

Carey FA, Sundberg RJ (1990) Advanced Organic Chemistry, 3rd edn. Plenum Press, New York

Andersen D, Storz T, Liu P, Wang X, Li L, Fan P, Chen X, Allgeier A, Burgos A, Tedrow J, Baum J, Chen Y, Crockett R, Huang L, Syed R, Larsen RD, Martinelli M (2007) J Organ Chem 72(25):9648–9655. doi:10.1021/jo701894v

Mackey SS, Wu H, Matison ME, Goble M (2005) Org Process Res Dev 9(2):174–178. doi:10.1021/op049799f

Ruiz M, Ojea V (1999) Synlett 02:204–206. doi:10.1055/s-1999-3155

Trabocchi A, Menchi G, Rolla M, Machetti F, Bucelli I, Guarna A (2003) Tetrahedron 59(28):5251–5258. doi:10.1016/S0040-4020(03)00773-7

Pandit CR, Mani NS (2009) Synthesis 2009:4032–4036. doi:10.1055/s-0029-1217050

Faul M, Larsen R, Levinson A, Tedrow J, Vounatsos F (2013) J Organ Chem 78(4):1655–1659. doi:10.1021/jo3023878

Ragan JA, am Ende DJ, Brenek SJ, Eisenbeis SA, Singer RA, Tickner DL, Teixeira JJ, Vanderplas BC, Weston N (2003) Org Process Res Dev 7(2):155–160. doi:10.1021/op0202235

Zhang J, Blazecka PG, Davidson JG (2003) Org Lett 5(4):553–556. doi:10.1021/ol0274662

Sheldon RA (2007) Green Chem 9(12):1273–1283. doi:10.1039/B713736M

Albal RS, Shah YT, Schumpe A, Carr NL (1983) Chem Eng J 27(2):61–80. doi:10.1016/0300-9467(83)80053-7

Sinhababu AK, Borchardt RT (1983) J Organ Chem 48(14):2356–2360. doi:10.1021/jo00162a011

Bayram E, Zahmakıran M, Özkar S, Finke RG (2010) Langmuir 26(14):12455–12464

Molecular Operating Environment (MOE) (2012) Chemical Computing Group, Inc., Montreal

Frisch MJ, Trucks GW, Schlegel HB, Scuseria GE, Robb MA, Cheeseman JR, Scalmani G, Barone V, Mennucci B, Petersson GA, Nakatsuji H, Caricato M, Li X, Hratchian HP, Izmaylov AF, Bloino J, Zheng G, Sonnenberg JL, Hada M, Ehara M, Toyota K, Fukuda R, Hasegawa J, Ishida M, Nakajima T, Honda Y, Kitao O, Nakai H, Vreven T, Montgomery JAJ, Peralta JE, Ogliaro F, Bearpark M, Heyd JJ, Brothers E, Kudin KN, Staroverov VN, Keith T, Kobayashi R, Normand J, Raghavachari K, Rendell A, Burant JC, Iyengar SS, Tomasi J, Cossi M, Rega N, Millam JM, Klene M, Knox JE, Cross JB, Bakken V, Adamo C, Jaramillo J, Gomperts R, Stratmann RE, Yazyev O, Austin AJ, Cammi R, Pomelli C, Ochterski JW, Martin RL, Morokuma K, Zakrzewski VG, Voth GA, P. Salvador P, Dannenberg JJ, Dapprich S, Daniels AD, Farkas O, Foresman JB, Ortiz JV, J. Cioslowski J, Fox DJ (2013) Gaussian 09. D.01 edn. Gaussian, Inc, Wallingford

Qudrat-I-Khuda M (1929) J Chem Soc (Resumed):201–209. doi:10.1039/JR9290000201

Wong JK, Lalancette RA, Thompson HW (2008) Open Crystallogr J 1:56–58

Ito K, Miyajima S (1986) Bull Chem Soc Jpn 59(3):815–818

Deimling A, Karandikar BM, Shah YT, Carr NL (1984) Chem Eng J 29(3):127–140. doi:10.1016/0300-9467(84)85038-8

Chaudhari RV, Gholap RV, Emig G, Hofmann H (1987) Can J Chem Eng 65(5):744–751. doi:10.1002/cjce.5450650506

Meille V, Pestre N, Fongarland P, de Bellefon C (2004) Ind Eng Chem Res 43(4):924–927. doi:10.1021/ie030569j

Singh UK, Krska SW, Sun Y (2006) Org Process Res Dev 10(6):1153–1156. doi:10.1021/op0601520

McConville FX (2002) The Pilot Plant Real Book. FXM Engineering and Design, Worcester

Jaganathan R, Ghugikar VG, Gholap RV, Chaudhari RV, Mills PL (1999) Ind Eng Chem Res 38(12):4634–4646. doi:10.1021/ie970670m

Mills PL, Chaudhari RV (1997) Catalysis Today 37(4):367–404. doi:10.1016/S0920-5861(97)00028-X

Acknowledgments

The authors thank Amgen Inc. for permission to publish this work.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Allgeier, A.M., Andersen, D., Bartberger, M.D. et al. Reductive Amination Without the Aldehyde: Use of a Ketolactol as an Aldehyde Surrogate. Top Catal 57, 1335–1341 (2014). https://doi.org/10.1007/s11244-014-0300-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-014-0300-x