Abstract

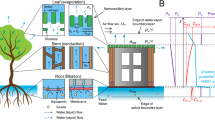

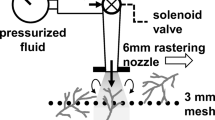

This paper reports the design of a vascular structure for an artificial tree, also known as an evaporation-driven porous substrate bioreactor (PSBR), for efficient biofuel production using microalgae. This system consists of multiple vertical ribs, each of which is made of porous membrane and grows algal cells on its surface as a biofilm. Nutrient medium flow through the reactor is driven by evaporation at the terminal end of the porous membrane, and nutrients are delivered from the porous membrane to the cells by diffusion. Flow through the membrane was modeled as a function of the physico-chemical and morphological properties of the membrane, as well as the environmental parameters governing evaporation. It was determined that under typical operating conditions, the evaporative flux from the evaporator region ranged from about 14 to 66 mg/m\(^2\) s. Moreover, there was a membrane pore radius that maximized nutrient medium flow as a result of the competition between capillary, viscous, and gravitational forces. For the range of evaporative fluxes observed in this study, this pore radius was about 10 \(\upmu \)m. Furthermore, a design example is provided for artificial trees made of three different commercially available membrane materials. A design methodology was demonstrated for maximizing photosynthetic productivity by tuning the evaporation-driven flow rate to ensure sufficient nutrient delivery to cells without incurring large evaporative loss rates. It was observed that both the growth rate and the evaporation-driven nutrient delivery rate were directly related to the irradiance in outdoor artificial trees, which provides a passive and efficient nutrient delivery mechanism. It is expected that the design principles along with the physical models governing the fluid flow in these vascular structures will aid researchers in developing novel applications for artificial trees.

Similar content being viewed by others

Abbreviations

- \(C\) :

-

Constant of proportionality for calculating nutrient delivery length

- \(D_\mathrm{w,a}\) :

-

Diffusivity of water vapor in air (m\(^2\)/s)

- \(G\) :

-

Irradiance (W/m\(^2\))

- \(Gr\) :

-

Grashof number

- \(h\) :

-

Height (m)

- \(h_\mathrm{c}\) :

-

Convection heat transfer coefficient (W/m\(^2\) K)

- \(h_\mathrm{fg}\) :

-

Heat of vaporization (J/kg)

- \(k\) :

-

Hydraulic permeability (m\(^2\))

- \(k_\omega \) :

-

Mass transfer coefficient (kg/m\(^2\) s)

- \(\dot{m}^{\prime }\) :

-

Mass flow rate per unit length (kg/s m)

- \(\dot{m_\mathrm{e}}^{\prime \prime }\) :

-

Evaporative flux (kg/m\(^2\) s)

- \(P\) :

-

Pressure (Pa)

- \(P_\mathrm{c}\) :

-

Capillary pressure (Pa)

- \(r\) :

-

Pore radius

- \(Re\) :

-

Reynolds number

- \(RH\) :

-

Relative humidity

- \(Sc\) :

-

Schmidt number

- \(Sh\) :

-

Sherwood number

- \(T\) :

-

Temperature (K)

- \(t\) :

-

Rib thickness (m)

- \(v_\mathrm{w}\) :

-

Wind speed (m/s)

- \(\dot{X}_o^{\prime \prime }\) :

-

Areal biomass production rate (kg/m\(^2\) s)

- \(x\) :

-

Distance in the direction of flow (m)

- \(x_\mathrm{c}\) :

-

Critical wetting length (m)

- \(x_\mathrm{ND}\) :

-

Nutrient delivery length (m)

- \(Y_{X/i_\mathrm{L}}\) :

-

Biomass yield based on nutrient \(i\) (kg/kmol)

- \(\alpha \) :

-

Absorptivity

- \(\epsilon \) :

-

Void fraction of porous membrane

- \(\mu \) :

-

Dynamic viscosity (Pa s)

- \(\omega \) :

-

Mass fraction

- \(\rho \) :

-

Mass density (kg/m\(^3\))

- \(\sigma \) :

-

Surface tension (N/m)

- \(\theta \) :

-

Contact angle (\(^{\circ }\))

- \(\infty \) :

-

Refers to ambient

- \(a\) :

-

Refers to air

- \(e\) :

-

Refers to exterior region

- \(f\) :

-

Refers to forced convection

- \(i\) :

-

Refers to interior region

- \(L\) :

-

Refers to limiting nutrient

- \(n\) :

-

Refers to natural convection

- \(r\) :

-

Refers to rib

References

Adham, S., Chiu, K.-P., Lehman, G., Mysore, C., Clouet, J.: Optimization of Membrane Treatment for Direct and Clarified Water Filtration, 1st edn. American Waterworks Foundation, New York (2006)

Andersen, R.A.: Algal Culturing Techniques. Elsevier Academic Press, London (2005)

Beal, C.M., Smith, C.H., Webber, M.E., Ruoff, R.S., Hebner, R.E.: A framework to report the production of renewable diesel from algae. Bioenergy Res. 4, 36–60 (2011)

Bird, R.B., Stewart, W.E., Lightfoot, E.N.: Transport Phenomena, 1st edn. Wiley, New York (1960)

Borowitzka, M.A.: Commercial production of microalgae: ponds, tanks, tubes, and fermenters. J. Biotechnol. 70, 313–321 (1999)

Chisti, Y.: Biodiesel from algae. Biotechnol. Adv. 25, 294–306 (2007)

Chisti, Y., Yan, J.: Energy from algae: current status and future trends. Appl. Energy 88(10), 3277–3279 (2011)

Clarens, A.F., Resurreccion, E.P., White, M.A., Colosi, L.M.: Environmental life cycle comparison of algae to other bioenergy feedstocks. Environ. Sci. Technol. 44(5), 1813–1819 (2010)

Craggs, R.J., Heubeck, S., Lundquist, T.J., Benemann, J.R.: Algal biofuels from wastewater treatment high rate algal ponds. Water Sci. Technol. 63(4), 660–665 (2011)

Day, J.G., Benson, E.E., Fleck, R.A.: In vitro culture and conservation of microalgae: applications for aquaculture, biotechnology and environmental research. In Vitro Cell Dev. Biol. 35, 127–136 (1999)

de Gennes, P.-G., Brochard-Wyart, F., Quere, D.: Capillarity and Wetting Phenomena: Drops, Bubbles, Pearls, Waves, 1st edn. Springer, New York (2004)

Incropera, F.P., Dewitt, D.P., Bergman, T.L., Lavine, A.S.: Fundamentals of Heat and Mass Transfer, 6th edn. Wiley, Hoboken (2007)

Jorquera, O., Kiperstok, A., Sales, E.A., Embiruçu, M., Ghirardi, M.L.: Comparative energy life-cycle analyses of microalgal biomass production in open ponds and photobioreactors. Bioresour. Technol. 101(4), 1406–1413 (2010)

Kaviany, M.: Principles of Heat Transfer in Porous Media, 2nd edn. Springer, New York (1999)

Kumar, K., Dasgupta, C.N., Nayak, B., Lindblad, P., Das, D.: Development of suitable photobioreactors for \(\text{ CO }_{2}\) sequestration addressing global warming using green algae and cyanobacteria. Bioresour. Technol. 102(8), 4945–4953 (2011)

Liu, T., Wang, J., Hu, Q., Cheng, P., Ji, B., Liu, J., Chen, Y., Zhang, W., Chen, X., Chen, L., Gao, L., Ji, C., Wang, H.: Attached cultivation technology of microalgae for efficient biomass feedstock production. Bioresour. Technol. 127, 216–222 (2013)

Milledge, J.J.: Commercial application of microalgae other than as biofuels: a brief review. Rev. Environ. Sci. Biotechnol. 10(1), 31–41 (2010)

Millington, R.J., Quirk, J.P.: Permeability of porous solids. Trans. Faraday Soc. 57, 1200–1207 (1961)

Mills, A.F.: Heat Transfer, 5th edn. Prentice-Hall, Upper Saddle River (1999)

Murphy, T.E., Berberoglu, H.: Flux balancing of light and nutrients in a biofilm pho- tobioreactor for maximizing photosynthetic productivity (accepted manuscript). Biotech- nol. Prog (2014)

Murphy, T.E., Fleming, E., Bebout, L., Bebout, B., Berberoglu, H.: A novel micro- bial cultivation platform for space applications. In: 1st Annual International Space Station Research and Development Conference, Denver (2012)

Naumann, T., Cebi, Z., Podola, B., Melkonian, M.: Growing microalgae as aquaculture feeds on twin-layers, a novel solid state photobioreactor. J. Appl. Phycol. 25, 1619 (2013)

Ozkan, A., Kinney, K., Katz, L., Berberoglu, H.: Reduction of water and energy requirement of algae cultivation using an algae biofilm photobioreactor. Bioresour. Technol. 114, 542–548 (2012)

Pasquini, D., Belgacem, M.N., Gandini, A., da Silva Curvelo, A.A.: Surface esterification of cellulose fibers: characterization by DRIFT and contact angle measurements. J. Colloid Interface Sci. 295(1), 79–83 (2006)

Pulz, O., Gross, W.: Valuable products from biotechnology of microalgae. Appl. Microbiol. Biotechnol. 65(6), 635–648 (2004)

Scott, S.A., Davey, M.P., Dennis, J.S., Horst, I., Howe, C.J., Lea-Smith, D.J., Smith, A.G.: Biodiesel from algae: challenges and prospects. Curr. Opin. Biotechnol. 21(3), 277–286 (2010)

Spolaore, P., Joannis-Cassan, C., Duran, E., Isambert, A.: Commercial applications of microalgae. J. Biosci. Bioeng. 101(2), 87–96 (2006)

Sumner, A.L., Menke, E.J., Dubowski, Y., Newberg, J.T., Penner, R.M., Hemminger, J.C., Wingen, L.M., Finlayson-Pitts, B.J.: The nature of water on surfaces of laboratory systems and implications for heterogeneous chemistry in the troposphere. Phys. Chem. Chem. Phys. 6, 604–613 (2004)

Wilcox, S., Marion, W.: Users manual for TMY3 data sets. Technical report, National Renewable Energy Laboratory, Golden (2008)

Acknowledgments

The authors would like to sincerely thank Dr. Carlos Hidrovo for his helpful discussions. The authors also gratefully acknowledge the financial support of the National Science Foundation (CBET-1125755) making this study possible.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Murphy, T.E., Fleming, E. & Berberoglu, H. Vascular Structure Design of an Artificial Tree for Microbial Cell Cultivation and Biofuel Production. Transp Porous Med 104, 25–41 (2014). https://doi.org/10.1007/s11242-014-0318-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-014-0318-3