Abstract

Purpose

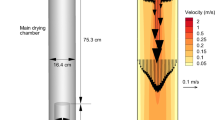

The purpose of this study was to develop a new computational fluid dynamics (CFD)-based model of the complex transport and droplet drying kinetics within a laboratory-scale spray dryer, and relate CFD-predicted drying parameters to powder aerosolization metrics from a reference dry powder inhaler (DPI).

Methods

A CFD model of the Buchi Nano Spray Dryer B-90 was developed that captured spray dryer conditions from a previous experimental study producing excipient enhanced growth powders with L-leucine as a dispersion enhancer. The CFD model accounted for two-way heat and mass transfer coupling between the phases and turbulent flow created by acoustic streaming from the mesh nebulizer. CFD-based drying parameters were averaged across all droplets in each spray dryer case and included droplet time-averaged drying rate (κavg), maximum instantaneous drying rate (κmax) and precipitation window.

Results

CFD results highlighted a chaotic drying environment in which time-averaged droplet drying rates (κavg) for each spray dryer case had high variability with coefficients of variation in the range of 60–70%. Maximum instantaneous droplet drying rates (κmax) were discovered that were two orders of magnitude above time-averaged drying rates. Comparing CFD-predicted drying parameters with experimentally determined mass median aerodynamic diameters (MMAD) and emitted doses (ED) from a reference DPI produced strong linear correlations with coefficients of determination as high as R2 = 0.98.

Conclusions

For the spray dryer system and conditions considered, reducing the CFD-predicted maximum drying rate experienced by droplets improved the aerosolization performance (both MMAD and ED) when the powders were aerosolized with a reference DPI.

Similar content being viewed by others

Abbreviations

- 3D:

-

Three dimensional

- AS:

-

Albuterol sulfate

- CFD:

-

Computational fluid dynamics

- CV:

-

Coefficient of variation

- DPI:

-

Dry powder inhaler

- ED:

-

Emitted dose

- EEG:

-

Excipient enhanced growth

- HPLC:

-

High performance liquid chromatography

- HPMC:

-

Hydroxypropyl methylcellulose

- ISR:

-

Time integral of saturation ratio

- LPM:

-

Liters per minute

- LRN:

-

Low Reynolds number

- MMAD:

-

Mass median aerodynamic diameters

- MN:

-

Mannitol

- MT:

-

Mouth-throat

- NGI:

-

Next Generation Impactor

- RH:

-

Relative humidity

- RMM:

-

Rapid mixing model

- SD:

-

Standard deviation

- SR:

-

Saturation ratio

- T:

-

Temperature

References

Weers JG, Miller DP. Formulation design of dry powders for inhalation. J Pharm Sci. 2015;104:3259–88.

Chan HK, Kwok PCL. Production methods for nanodrug particles using the bottom-up approach. Adv Drug Deliv Rev. 2011;63:406–16.

Vehring R. Pharmaceutical particle engineering via spray drying. Pharm Res. 2008;25:999–1022.

Bird RB, Steward WE, Lightfoot EN. Transport phenomena. New York: John Wiley & Sons; 2002.

Masters K. Spray drying—an Introduction to principles. Leonard Hill: Operational Practice and Applications; 1972.

Finlay WH. The mechanics of inhaled pharmaceutical aerosols. San Diego: Academic Press; 2001.

Vehring R, Foss WR, Lechuga-Ballesteros D. Particle formation in spray drying. J Aerosol Sci. 2007;38:728–46.

Hoe S, Ivey JW, Boraey MA, Shamsaddini-Shahrbabak A, Javaheri E, Matinkhoo S, et al. Use of a fundamental approach to spray-drying formulation design to facilitate the development of multi-component dry powder aerosols for respiratory drug delivery. Pharm Res. 2014;31:449–65.

Chan H-K. Dry powder aerosol drug delivery - Opportunities for colloid and surface scientists. Colloids and Surfaces A: Physicochem. Eng. Aspects. 2006;284–285:50–55.

Vicente J, Pinto J, Menezes J, Gaspar F. Fundamental analysis of particle formation in spray drying. Powder Technol. 2013;247:1–7.

Weers JG, Son Y-J, Glusker M, Haynes A, Huang D, Kadrichu N, et al. Idealhalers versus realhalers: is it possible to bypass deposition in the upper respiratory tract? Journal of Aerosol Medicine and Pulmonary Drug Delivery. 2019;32:55–69.

Delvadia R, Hindle M, Longest PW, Byron PR. In vitro tests for aerosol deposition II: IVIVCs for different dry powder inhalers in normal adults. Journal of Aerosol Medicine and Pulmonary Drug Delivery. 2013;26:138–44.

Newman SP, Busse WW. Evolution of dry powder inhaler design, formulation, and performance. Respir Med. 2002;96:293–304.

Son Y-J, Longest PW, Hindle M. Aerosolization characteristics of dry powder inhaler formulations for the excipient enhanced growth (EEG) application: effect of spray drying process conditions on aerosol performance. Int J Pharm. 2013;443:137–45.

Son Y-J, Longest PW, Tian G, Hindle M. Evaluation and modification of commercial dry powder inhalers for the aerosolization of submicrometer excipient enhanced growth (EEG) formulation. Eur J Pharm Sci. 2013;49:390–9.

Behara SRB, Longest PW, Farkas DR, Hindle M. Development and comparison of new high-efficiency dry powder inhalers for carrier-free formulations. J Pharm Sci. 2014;103:465–77.

Farkas D, Hindle M, Longest PW. Application of an inline dry powder inhaler to deliver high dose pharmaceutical aerosols during low flow nasal cannula therapy. Int J Pharm. 2018;546:1–9.

Farkas D, Hindle M, Longest PW. Efficient nose-to-lung aerosol delivery with an inline DPI requiring low actuation air volume. Pharm Res. 2018;35:194.

Farkas D, Hindle M, Bonasera S, Bass K, and Longest W. Development of an inline dry powder inhaler for oral or trans-nasal aerosol administration to children. Journal of Aerosol Medicine and Pulmonary Drug Delivery. 2019;DOI: https://doi.org/10.1089/jamp.2019.1540

Geller DE, Weers J, Heuerding S. Development of an inhaled dry-powder formulation of tobramycin using PulmoSphereTM technology. Journal of Aerosol Medicine and Pulmonary Drug Delivery. 2011;24:175–82.

Feng A, Boraey M, Gwin M, Finlay P, Kuehl P, Vehring R. Mechanistic models facilitate efficient development of leucine containing microparticles for pulmonary drug delivery. Int J Pharm. 2011;409:156–63.

Baldelli A, Vehring R. Control of the radial distribution of chemical components in spray-dried crystalline microparticles. Aerosol Sci Technol. 2016;50:1130–42.

Son Y-J, Longest PW, and Hindle M. Aerosolization characteristics of dry powder inhaler formulations for the enhanced excipient growth application: Effect of spray drying conditions. Respiratory Drug Delivery 2012. 2012;3:899–902.

Baldelli A, Power RM, Miles RE, Reid JP, Vehring R. Effect of crystallization kinetics on the properties of spray-dried microparticles. Aerosol Sci Technol. 2016;50:693–704.

Baldelli A, Boraey MA, Nobes DS, Vehring R. Analysis of the particle formation process of structured microparticles. Mol Pharm. 2015;12:2562–73.

Ferziger JH, Peric M. Computational methods for fluid dynamics. Berlin: Springer-Verlag; 1999.

Longest PW, Spence BM, Holbrook LT, Mossi KM, Son Y-J, Hindle M. Production of inhalable submicrometer aerosols from conventional mesh nebulizers for improved respiratory drug delivery. J Aerosol Sci. 2012;51:66–80.

Longest PW, Hindle M. Condensational growth of combination drug-excipient submicrometer particles: comparison of CFD predictions with experimental results. Pharm Res. 2012;29:707–21.

Longest PW, Walenga RL, Son Y-J, Hindle M. High efficiency generation and delivery of aerosols through nasal cannula during noninvasive ventilation. Journal of Aerosol Medicine and Pulmonary Drug Delivery. 2013;26:266–79.

Poozesh S, Lu K, Marsac PJ. On the particle formation in spray drying process for bio-pharmaceutical applications: interrogating a new model via computational fluid dynamics. Int J Heat Mass Transf. 2018;122:863–76.

Ramachandran RP, Akbarzadeh M, Paliwal J, Cenkowski S. Computational fluid dynamics in drying process modelling—a technical review. Food Bioprocess Technol. 2018;11:271–92.

Longest PW, Tian G, Li X, Son Y-J, Hindle M. Performance of combination drug and hygroscopic excipient submicrometer particles from a softmist inhaler in a characteristic model of the airways. Ann Biomed Eng. 2012;40:2596–610.

Hindle M, Longest PW. Condensational growth of combination drug-excipient submicrometer particles for targeted high efficiency pulmonary delivery: evaluation of formulation and delivery device. J Pharm Pharmacol. 2012;64:1254–63.

Tian G, Longest PW, Li X, Hindle M. Targeting aerosol deposition to and within the lung airways using excipient enhanced growth. Journal of Aerosol Medicine and Pulmonary Drug Delivery. 2013;26:248–65.

Schmid K, Arpagaus C, Friess W. Evaluation of the Nano spray dryer B-90 for pharmaceutical applications. Pharm Dev Technol. 2011;16:287–94.

Zhang G, David A, Wiedmann TS. Performance of the vibrating membrane aerosol generation device: Aeroneb micropump nebulizer. Journal of Aerosol Medicine. 2007;20:408–16.

Spence BM, Longest PW, Wei X, Dhapare S, and Hindle M. Development of a high flow nasal cannula (HFNC) and pharmaceutical aerosol combination device. Journal of Aerosol Medicine and Pulmonary Drug Delivery. 2019;DOI: https://doi.org/10.1089/jamp.2018.1488

Ghazanfari T, Elhissi AMA, Ding Z, Taylor KMG. The influence of fluid physicochemical properties on vibrating-mesh nebulization. Int J Pharm. 2007;339:103–11.

Nyborg WL. Acoustic streaming due to attenuated plane waves. The Journal of the Acoustical Society of America. 1953;25:68–75.

Trujillo FJ, Knoerzer K. A computational modeling approach of the jet-like acoustic streaming and heat generation induced by low frequency high power ultrasonic horn reactors. Ultrason Sonochem. 2011;18:1263–73.

Wilcox DC. Turbulence modeling for CFD, 2nd Ed., DCW Industries, Inc., California, 1998.

Longest PW, Hindle M, Das Choudhuri S, Byron PR. Numerical simulations of capillary aerosol generation: CFD model development and comparisons with experimental data. Aerosol Sci Technol. 2007;41:952–73.

Longest PW, Tian G, Delvadia R, Hindle M. Development of a stochastic individual path (SIP) model for predicting the deposition of pharmaceutical aerosols: effects of turbulence, polydisperse aerosol size, and evaluation of multiple lung lobes. Aerosol Sci Technol. 2012;46:1271–85.

Longest PW, Tian G, Walenga RL, Hindle M. Comparing MDI and DPI aerosol deposition using in vitro experiments and a new stochastic individual path (SIP) model of the conducting airways. Pharm Res. 2012;29:1670–88.

Tian G, Longest PW, Su G, Walenga RL, Hindle M. Development of a stochastic individual path (SIP) model for predicting the tracheobronchial deposition of pharmaceutical aerosols: effects of transient inhalation and sampling the airways. J Aerosol Sci. 2011;42:781–99.

Bird RB, Steward WE, Lightfoot EN. Transport phenomena. New York: John Wiley & Sons; 1960.

Green DW. Perry's chemical Engineers' handbook. New York: McGraw-Hill; 1997.

Vargaftik NB. Tables on Thermophysical properties of liquids and gases. Washington, DC: Hemisphere; 1975.

Vincenti WG, and Kruger CH. Physical Gas Dynamics, Robert E. Krieger Publishing Company, Inc., Malabar, 1986.

Longest PW, Xi J. Effectiveness of direct Lagrangian tracking models for simulating nanoparticle deposition in the upper airways. Aerosol Sci Technol. 2007;41:380–97.

Vinchurkar S, Longest PW. Evaluation of hexahedral, prismatic and hybrid mesh styles for simulating respiratory aerosol dynamics. Computers and Fluids. 2008;37:317–31.

Gosman AD, Ioannides E. Aspects of computer simulation of liquid-fueled combustors. Journal of Energy. 1981;7:482–90.

Bass K, Longest PW. Recommendations for simulating microparticle deposition at conditions similar to the upper airways with two-equation turbulence models. J Aerosol Sci. 2018;119:31–50.

Longest PW, Kleinstreuer C. Computational models for simulating multicomponent aerosol evaporation in the upper respiratory airways. Aerosol Sci Technol. 2005;39:124–38.

Ordoubadi M, Gregson FK, Melhem O, Barona D, Miles RE, D’Sa D, et al. Multi-solvent microdroplet evaporation: modeling and measurement of spray-drying kinetics with inhalable pharmaceutics. Pharm Res. 2019;36:100.

Fuchs NA, Sutugin AG. Highly dispersed aerosols. Ann Arbor: Ann Arbor Science Publ; 1970.

Clift R, Grace JR, Weber ME. Bubbles, drops, and particles. New York: Academic Press; 1978.

Leong K. Morphological control of particles generated from the evaporation of solution droplets: theoretical considerations. J Aerosol Sci. 1987;18:511–24.

Lee SH, Heng D, Ng WK, Chan H-K, Tan RB. Nano spray drying: a novel method for preparing protein nanoparticles for protein therapy. Int J Pharm. 2011;403:192–200.

Li L, Leung SSY, Gengenbach T, Yu J, Gao GF, Tang P, et al. Investigation of L-leucine in reducing the moisture-induced deterioration of spray-dried salbutamol sulfate power for inhalation. Int J Pharm. 2017;530:30–9.

Belotti S, Rossi A, Colombo P, Bettini R, Rekkas D, Politis S, et al. Spray-dried amikacin sulphate powder for inhalation in cystic fibrosis patients: the role of ethanol in particle formation. Eur J Pharm Biopharm. 2015;93:165–72.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Longest, P.W., Farkas, D., Hassan, A. et al. Computational Fluid Dynamics (CFD) Simulations of Spray Drying: Linking Drying Parameters with Experimental Aerosolization Performance. Pharm Res 37, 101 (2020). https://doi.org/10.1007/s11095-020-02806-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11095-020-02806-y