Abstract

Purpose

To study the effects of physicochemical properties of drug and polymer, as well as the drug-polymer interactions, on the surface composition of SDDs.

Methods

Ethanol solutions containing a model drug (IMC, NMP or FCZ) and a model polymer (PVPK12, PVPK30 or PVP-VA) were spray dried, and the surface composition of SDDs was analyzed by XPS. The surface tensions of pure components and their solutions were measured using Wilhelmy plate and/or calculated using ACD/Labs. NMR and DLS were used to obtain the diffusion coefficients of IMC, NMP, PVPK12 and PVPK30 in solvents. Flory-Huggins interaction parameters for selected drug-polymer pairs were obtained using a melting point depression method.

Results

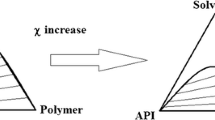

Significant surface enrichment or depletion of the drug was observed in SDDs depending on the particular drug-polymer combination. With PVP as the dispersion polymer, IMC and NMP were surface enriched; whereas FCZ, a hydrophilic drug, was surface depleted. With increasing PVP molecular weight, the surface drug concentration increased, and the effect was greater in the NMP/PVP and FCZ/PVP systems than in the IMC/PVP system where strong drug-polymer interaction existed. Changing the polymer from PVP to PVP-VA reduced the surface concentration of the drug.

Conclusions

The surface concentration of a SDD can be significantly different from the bulk concentration. The main results of this work are consistent with the notion that the relative surface tensions control surface enrichment or depletion. Besides, the relative diffusion rates of the components and the strength of their interactions may also affect the surface composition of the SDDs.

Similar content being viewed by others

Abbreviations

- DLS:

-

Dynamic light scattering

- DOSY:

-

Diffusion-ordered spectroscopy

- DSC:

-

Differential scanning calorimetry

- FCZ:

-

Fluconazole

- HPLC:

-

High performance liquid chromatography

- IMC:

-

Indomethacin

- NMP:

-

Nimodipine

- NMR:

-

Nuclear magnetic resonance

- PVP:

-

Poly(vinyl pyrrolidone)

- PVP-VA:

-

Poly(vinyl pyrrolidone − vinyl acetate) copolymer

- SDD:

-

Spray dried dispersion

- SEM:

-

Scanning electron microscopy

- VP dimer:

-

Dimer of vinyl pyrrolidone

- XPS:

-

X-ray photoelectron spectroscopy

References

Ré M-I. Formulating drug delivery systems by spray drying. Dry Technol. 2006;24(4):433–46.

Vehring R. Pharmaceutical particle engineering via spray drying. Pharm Res. 2008;25(5):999–1022.

Sollohub K, Cal K. Spray drying technique: II. Current applications in pharmaceutical technology. J Pharm Sci. 2010;99(2):587–97.

Peltonen L, Valo H, Kolakovic R, Laaksonen T, Hirvonen J. Electrospraying, spray drying and related techniques for production and formulation of drug nanoparticles. Expert Opin Drug Del. 2010;7(6):705–19.

Chauhan B, Shimpi S, Paradkar A. Preparation and evaluation of glibenclamide-polyglycolized glycerides solid dispersions with silicon dioxide by spray drying technique. Eur J Pharm Sci. 2005;26(2):219–30.

Willart JF, Descamps M. Solid state amorphization of pharmaceuticals. Mol Pharm. 2008;5(6):905–20.

Friesen DT, Shanker R, Crew M, Smithey DT, Curatolo W, Nightingale J. Hydroxypropyl methylcellulose acetate succinate-based spray-dried dispersions: an overview. Mol Pharm. 2008;5(6):1003–19.

Charlesworth DH, Marshall WR. Evaporation from drops containing dissolved solids. AICHE J. 1960;6(1):9–23.

Dlouhy J, Gauvin WH. Evaporation rates in spray drying. Can J Chem Eng. 1960;38(4):113–20.

Birchal VS, Huang L, Mujumdar AS, Passos ML. Spray dryers: modeling and simulation. Dry Technol. 2006;24(3):359–71.

Martens R, Naudts M. Influence of process variables on some whole milk powder characteristics. Milchwissenschaft. 1976;31:396–401.

Alexander K, Judson King C. Factors governing surface morphology of spray-dried amorphous substances. Dry Technol. 1985;3(3):321–48.

Wallack DA, El-Sayed TM, King CJ. Changes in particle morphology during drying of drops of carbohydrate solutions and food liquids. 2. Effects on drying rate. Ind Eng Chem Res. 1990;29(12):2354–7.

Kelly J, Kelly PM, Harrington D. Influence of processing variables on the physicochemical properties of spray dried fat-based milk powders. Lait. 2002;82(4):401–12.

Paudel A, Worku ZA, Meeus J, Guns S, Van den Mooter G. Manufacturing of solid dispersions of poorly water soluble drugs by spray drying: formulation and process considerations. Int J Pharm. 2013;453(1):253–84.

Matsumoto T, Zografi G. Physical properties of solid molecular dispersions of indomethacin with poly(vinylpyrrolidone) and poly(vinylpyrrolidone-co-vinyl-acetate) in relation to indomethacin crystallization. Pharm Res. 1999;16(11):1722–8.

Yu L. Amorphous pharmaceutical solids: preparation, characterization and stabilization. Adv Drug Deliver Rev. 2001;48(1):27–42.

Saad M, Gaiani C, Mullet M, Scher J, Cuq B. X-Ray photoelectron spectroscopy for wheat powders: measurement of surface chemical composition. J Agr Food Chem. 2011;59(5):1527–40.

Guascito MR, Cesari D, Chirizzi D, Genga A, Contini D. XPS surface chemical characterization of atmospheric particles of different sizes. Atmos Environ. 2015;116:146–54.

Kim EHJ, Chen XD, Pearce D. Surface composition of industrial spray-dried milk powders. 1. Development of surface composition during manufacture. J Food Eng. 2009;94(2):163–8.

Kim EHJ, Chen XD, Pearce D. Surface composition of industrial spray-dried milk powders. 2. Effects of spray drying conditions on the surface composition. J Food Eng. 2009;94(2):169–81.

Gaiani C, Ehrhardt J, Scher J, Hardy J, Desobry S, Banon S. Surface composition of dairy powders observed by X-ray photoelectron spectroscopy and effects on their rehydration properties. Colloids Surf B: Biointerfaces. 2006;49(1):71–8.

Kim EHJ, Xiao DC, Pearce D. Effect of surface composition on the flowability of industrial spray-dried dairy powders. Colloids Surf B: Biointerfaces. 2005;46(3):182–7.

Chen XD, Sidhu H, Nelson M. Theoretical probing of the phenomenon of the formation of the outermost surface layer of a multi-component particle, and the surface chemical composition after the rapid removal of water in spray drying. Chem Eng Sci. 2011;66(24):6375–84.

Williams DR. Particle engineering in pharmaceutical solids processing: surface energy considerations. Curr Pharm Design. 2015;21(19):2677–94.

Wan F, Bohr A, Maltesen MJ, Bjerregaard S, Foged C, Rantanen J, et al. Critical solvent properties affecting the particle formation process and characteristics of celecoxib-loaded PLGA microparticles via spray-drying. Pharm Res. 2013;30(4):1065–76.

Kim EHJ, Chen XD, Pearce D. On the mechanisms of surface formation and the surface compositions of industrial milk powders. Dry Technol. 2003;21(2):265–78.

Nikolova Y, Petit J, Gianfrancesco A, Sanders CFW, Scher J, Gaiani C. Impact of spray-drying process parameters on dairy powder surface composition and properties. Dry Technol. 2015;33(13):1654–61.

Wang S, Langrish TAG. A distributed parameter model for particles in the spray drying process. Adv Powder Technol. 2009;20(3):220–6.

Porowska A, Dosta M, Heinrich S, Fries L, Gianfrancesco A, Palzer S. Influence of feed composition and drying parameters on the surface composition of a spray-dried multicomponent particle. Dry Technol. 2015;33(15–16):1911–9.

Foerster M, Gengenbach T, Woo MW, Selomulya C. The impact of atomization on the surface composition of spray-dried milk droplets. Colloids Surf B: Biointerfaces. 2016;140:460–71.

Foerster M, Gengenbach T, Woo MW, Selomulya C. The influence of the chemical surface composition on the drying process of milk droplets. Adv Powder Technol. 2016;27(6):2324–34.

Porowska A, Dosta M, Fries L, Gianfrancesco A, Heinrich S, Palzer S. Predicting the surface composition of a spray-dried particle by modelling component reorganization in a drying droplet. Chem Eng Res Des. 2016;110:131–40.

Vehring R, Foss WR, Lechuga-Ballesteros D. Particle formation in spray drying. J Aerosol Sci. 2007;38(7):728–46.

Tao J, Sun Y, Zhang GGZ, Yu L. Solubility of small-molecule crystals in polymers: D-mannitol in PVP, indomethacin in PVP/VA, and nifedipine in PVP/VA. Pharm Res. 2009;26(4):855–64.

Davies MC, Wilding IR, Short RD, Khan MA, Watts JF, Melia CD. An analysis of the surface chemical structure of polymethacrylate (Eudragit) film coating polymers by XPS. Int J Pharm. 1989;57(3):183–7.

de Gennes PG. Polymer solutions near an interface. 1. Adsorption and depletion layers. Macromolecules. 1981;14(6):1637–44.

Ober R, Paz L, Taupin C, Pincus P, Boileau S. Study of the surface tension of polymer solutions: theory and experiments. 1. Good solvent conditions. Macromolecules. 1983;16(1):50–5.

Legrand DG, Gaines GL. The molecular weight dependence of polymer surface tension. J Colloid Interface Sci. 1969;31(2):162–7.

Jalbert C, Koberstein JT, Yilgor I, Gallagher P, Krukonis V. Molecular weight dependence and end-group effects on the surface tension of poly(dimethylsiloxane). Macromolecules. 1993;26(12):3069–74.

Sun YE, Tao J, Zhang GGZ, Yu L. Solubilities of crystalline drugs in polymers: an improved analytical method and comparison of solubilities of indomethacin and nifedipine in PVP, PVP/VA, and PVAc. J Pharm Sci. 2010;99(9):4023–31.

Adler M, Unger M, Lee G. Surface composition of spray-dried particles of bovine serum albumin/trehalose/surfactant. Pharm Res. 2000;17(7):863–70.

Nuzzo M, Millqvist-Fureby A, Sloth J, Bergenstahl B. Surface composition and morphology of particles dried individually and by spray drying. Dry Technol. 2015;33(6):757–67.

Ausserre D, Hervet H, Rondelez F. Concentration dependence of the interfacial depletion layer thickness for polymer solutions in contact with nonadsorbing walls. Macromolecules. 1986;19(1):85–8.

Lee LT, Guiselin O, Lapp A, Farnoux B, Penfold J. Direct measurements of polymer depletion layers by neutron reflectivity. Phys Rev Lett. 1991;67(20):2838–41.

Acknowledgments and Disclosures

This research is supported by China National Nature Science Foundation (Project Number 81573355), and Janssen Pharmaceuticals, Inc., a pharmaceutical company of Johnson & Johnson. FQ also acknowledges the funds provided by the Center for Life Sciences at Tsinghua and Peking Universities (Beijing, China) and by the China Recruitment Program of Global Experts. LY acknowledges partial support by the Bill and Melinda Gates Foundation.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Guest Editors: Tony Zhou and Tonglei Li

Rights and permissions

About this article

Cite this article

Chen, Z., Yang, K., Huang, C. et al. Surface Enrichment and Depletion of the Active Ingredient in Spray Dried Amorphous Solid Dispersions. Pharm Res 35, 38 (2018). https://doi.org/10.1007/s11095-018-2345-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11095-018-2345-1