Abstract

Described is the synthesis of metal (Ni, Cr, and Mn) doped macro/mesoporous carbon monoliths by co-polymerization of transition metal complexes with resorcinol/formaldehyde and subsequent pyrolysis. Two salen ligands were synthesized via reaction of ethylene diamine (EDA) and 1,6-diaminohexane (DAH) with 2,4-dihydroxybenzaldehyde to give 4,4′-((1E,1′E)-(ethane-1,2-diylbis(azanylylidene))bis(methanylylidene))bis(benzene-1,3-diol) (=E-salen) and 4,4′-((1E,1′E)-(hexane-1,6-diylbis(azanylylidene))bis(methanylylidene))bis(benzene-1,3-diol) (=D-salen). Their metal salen complexes were prepared. All the samples pyrolyzed at 500 °C had macro and mesopores with a specific surface area ranging from 250–500 m2/g. However, the surface area and porosity of the samples decreased dramatically for the metal containing samples pyrolyzed at 800 °C. This is suggested to result from incomplete co-polymerization of the metal salen complexes. The extent of graphitization determined from Raman increased with the pyrolysis temperature. The electrical conductivity was found to increase with the pyrolysis temperature, and followed the trend Ni > Mn > Cr. The M-E-salen containing samples had significantly lower conductivity than their D-salen counterparts.

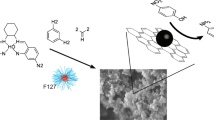

Graphical abstract

Similar content being viewed by others

References

Świątkowski A (1999) Industrial carbon adsorbents. In: Dąbrowski A (ed) Adsorption and its applications in industry and environmental protection, vol. 120. Part A. Elsevier, New York, pp 69–94. http://dx.doi.org.libdata.lib.ua.edu/10.1016/S0167-2991(99)80549-7

Mezohegyi G, van der Zee FP, Font J, Fortuny A, Fabregat A (2012) Towards advanced aqueous dye removal processes: A short review on the versatile role of activated carbon. J Environ Manage 102:148–164. https://doi.org/10.1016/j.jenvman.2012.02.021

Moreno-Castilla C, Rivera-Utrilla J (2001) Carbon materials as adsorbents for the removal of pollutants from the aqueous phase. Mater Res Bull 26(11):890–894. https://doi.org/10.1557/mrs2001.230

Menéndez-Díaz JA, Martín-Gullón I (2006) Types of carbon adsorbents and their production. In: Bandosz TJ (ed) Activated carbon surfaces in environmental remediation, Vol 7. Interface Science and Technology, pp 1-47. https://doi.org/10.1016/S1573-4285(06)80010-4

Sevilla M, Mokaya R (2014) Energy storage applications of activated carbons: supercapacitors and hydrogen storage. Energy Environ Sci 7:1250–1280. https://doi.org/10.1039/c3ee43525c

Rodriguez-Reinoso F (2005) Carbon as a catalyst support. In: Patrick JW (ed) Porosity in Carbons, Halsted Press, New York, NY, pp 253–290

Lam E, Luong JHT (2014) Carbon materials as catalyst supports and catalysts in the transformation of biomass to fuels and chemicals. ACS Catal 4:3393–3410. https://doi.org/10.1021/cs5008393

Yao F, Pham DT, Lee YH (2015) Carbon-based materials for lithium-ion batteries, electrochemical capacitors, and their hybrid devices. ChemSusChem 8:2284–2311. https://doi.org/10.1002/cssc.201403490

Simon P, Gogotsi Y (2008) Materials for electrochemical capacitors. Nat Mater 7:845–854. https://doi.org/10.1038/nmat2297

Chen Z, Higgins D, Yu A, Zhang L, Zhang J (2011) A review on non-precious metal electrocatalysts for PEM fuel cells. Energy Environ Sci 4:3167–3192. https://doi.org/10.1039/c0ee00558d

Yang Y, Chiang K, Burke N (2011) Porous carbon-supported catalysts for energy and environmental applications: A short review. Catal Today 178(1):197–205. https://doi.org/10.1016/j.cattod.2011.08.028

Xia Y, Yang Z, Mokaya R (2010) Templated nanoscale porous carbons. Nanoscale 2:639–659. https://doi.org/10.1039/b9nr00207c

Biener J, Stadermann M, Suss M, Worsley MA, Biener MM, Rose KA, Baumann TF (2011) Advanced carbon aerogels for energy applications. Energy Environ Sci 4:656–667. https://doi.org/10.1039/c0ee00627k

Chuenchom L, Kraehnert R, Smarsly BM (2012) Recent progress in soft-templating of porous carbon materials. Soft Matter 8:10801–10812. https://doi.org/10.1039/c2sm07448f

Fang B, Kim JH, Kim M-S, Yu J-S (2013) Hierarchical nanostructured carbons with meso-macroporosity: design, characterization, and applications. Acc Chem Res 46(7):1397–1406. https://doi.org/10.1021/ar300253f

Li X, Sun M, Rooke JC, Chen L, Su BL (2013) Synthesis and applications of hierarchically porous catalysts. Chin J Catal 34:22–47. https://doi.org/10.1016/S1872-2067(11)60507-X

Dutta S, Bhaumik A, Wu KCW (2014) Hierarchically porous carbon derived from polymers and biomass: effect of interconnected pores on energy applications. Energy Environ Sci 7(11):3574–3592. https://doi.org/10.1039/C4EE01075B

Hao G-P, Li W-C, Qian D, Lu A-H (2010) Rapid synthesis of nitrogen-doped porous carbon monolith for CO2 capture. Adv Mater 22:853–857. https://doi.org/10.1002/adma.200903765

Hao G-P, Li W-C, Qian D, Wang G-H, Zhang W-P, Zhang T, Wang A-Q, Schuth F, Bongard H-J, Lu A-H (2011) Structurally designed synthesis of mechanically stable poly(benzoxazine-co-resol)-based porous carbon monoliths and their application as high-performance CO2 capture sorbents. J Am Chem Soc 133:11378–11388. https://doi.org/10.1021/ja203857g

Hao G-P, Li W-C, Wang S, Wang G-H, Qi L, Lu A-H (2011) Lysine-assisted rapid synthesis of crack-free hierarchical carbon monoliths with a hexagonal array of mesopores. Carbon 49(12):3762–3772. https://doi.org/10.1016/j.carbon.2011.05.010

Lipatov YS, Alekseeva TT (2007) Phase-separated interpenetrating polymer networks. Adv Polym Sci 208:1–227. https://doi.org/10.1007/12_2007_116

Ignatova TD, Kosyanchuk LF, Todosiychuk TT, Nesterov AE (2011) Reaction-induced phase separation and structure formation in polymer blends. Composite Interf 18:185–236. https://doi.org/10.1163/092764411X567530

van Dillen AJ, Terorde RJAM, Lensveld DJ, Geus JW, de Jong KP (2003) Synthesis of supported catalysts by impregnation and drying using aqueous chelated metal complexes. J Catal 216:257–264. https://doi.org/10.1016/S0021-9517(02)00130-6

Marceau E, Carrier X, Che M (2009) Impregnation and drying. In: de Jong KP (ed) Synthesis of Solid Catalysts, Wiley-VCH, Weinheim, Germany, pp 59–82. https://doi.org/10.1002/9783527626854.ch4

Regalbuto JR (2009) Electrostatic adsorption. In: de Jong KP (ed) Synthesis of Solid Catalysts, Wiley-VCH, Weinheim, Germany, pp 33–58. https://doi.org/10.1002/9783527626854.ch3

Liu S-H, Lu R-F, Huang S-J, Lo A-Y, Chien S-H, Liu S-B (2006) Controlled synthesis of highly dispersed platinum nanoparticles in ordered mesoporous carbons. Chem Comm 3435–3437. https://doi.org/10.1039/b607449a

Gao P, Wang A, Wang X, Zhang T (2008) Synthesis of highly ordered Ir-containing mesoporous carbon materials by organic–organic self-assembly. Chem Mater 20:1881–1888. https://doi.org/10.1021/cm702815e

Wang X, Dai S (2009) A simple method to ordered mesoporous carbons containing nickel nanoparticles. Adsorption 15:138–144. https://doi.org/10.1007/s10450-009-9164-y

Yao J, Li L, Song H, Liu C, Chen X (2009) Synthesis of magnetically separable ordered mesoporous carbons from F127/[Ni(H2O)6](NO3)2/resorcinol-formaldehyde composites. Carbon 47:436–444. https://doi.org/10.1016/j.carbon.2008.10.016

Zhai Y, Dou Y, Liu X, Tua B, Zhao D (2009) One-pot synthesis of magnetically separable ordered mesoporous carbon. J Mater Chem 19:3292–3300. https://doi.org/10.1039/b821945a

Sun Z, Sun B, Qiao M, Wei J, Yue Q, Wang C, Deng Y, Kaliaguine S, Zhao D (2012) A general chelate-assisted co-assembly to metallic nanoparticles-incorporated ordered mesoporous carbon catalysts for Fischer−tropsch synthesis. J Am Chem Soc 134:17653–17660. https://doi.org/10.1021/ja306913x

Wei J, Zhou D, Sun Z, Deng Y, Xia Y, Zhao D (2013) A controllable synthesis of rich nitrogen-doped ordered mesoporous carbon for CO2 capture and supercapacitors. Adv Funct Mater 23:2322–2328. https://doi.org/10.1002/adfm.201202764

Kotbagi TV, Hakat Y, Bakker MG (2015) Novel one-pot synthesis of hierarchically porous Pd/C monoliths by a co-gelation method. MRS Commun 5:51–56. https://doi.org/10.1557/mrc.2015.7

Kotbagi TV, Hakat Y, Bakker MG (2016) Facile one-pot synthesis and characterization of nickel supported on hierarchically porous carbon. Mater Res Bull 73:204–210. https://doi.org/10.1016/j.materresbull.2015.09.006

Kotbagi TV, Gurav HR, Nagpure AS, Chilukuri SV, Bakker MG (2016) Robust and recyclable nitrogen doped hierarchically porous carbon supported Ni nanoparticles for the hydrogenation of furfural to furfuryl alcohol. RSC Adv 6:67662–67668. https://doi.org/10.1039/C6RA14078E

Liu Y, Li D, Lin B, Sun Y, Zhang X, Yang H (2015) Hydrothermal synthesis of Ni-doped hierarchically porous carbon monoliths for hydrogen storage. J Porous Mat 22:1417–1422. https://doi.org/10.1007/s10934-015-0021-y

Oya A, Marsh H (1982) Phenomena of catalytic graphitization. J Mater Sci 17:309–322

Oya A, Otani S (1981) Influences of particle size of metal on catalytic graphitization of non-graphitizing. Carbon 19(5):391–400. https://doi.org/10.1016/0008-6223(81)90064-6

Maldonado-Hodar FJ, Moreno-Castilla C, Rivera-Utrilla J, Hanzawa Y, Yamada Y (2000) Catalytic graphitization of carbon aerogels by transition metals. Langmuir 16:4367–4373. https://doi.org/10.1021/la991080r

Hao G-P, Han F, Guo D-C, Fan R-J, Xiong G, Li W-C, Lu A-H (2012) Monolithic carbons with tailored crystallinity and porous structure as lithium-ion anodes for fundamental understanding their rate performance and cycle stability. J Phys Chem C 116:10303–10311. https://doi.org/10.1021/jp2124229

Sevilla M, Fuertes AB (2013) Fabrication of porous carbon monoliths with a graphitic framework. Carbon 56:155–156. https://doi.org/10.1016/j.carbon.2012.12.090

Li J, Gu J, Li H, Liang Y, Hao Y, Sun X, Wang L (2010) Synthesis of highly ordered Fe-containing mesoporous carbon materials using soft templating routes. Micropor Mesopor Mater 128:144–149. https://doi.org/10.1016/j.micromeso.2009.08.015

Chi Y, Tu J, Wang M, Li X, Zhao Z (2014) One-pot synthesis of ordered mesoporous silver nanoparticle/carbon composites for catalytic reduction of 4-nitrophenol. J Coll Interf Sci 423:54–59. https://doi.org/10.1016/j.jcis.2014.02.029

Ghimbeu CM, Meins J-ML, Zlotea C, Vidal L, Schrodj G, Latroche M, Vix-Guterl C (2014) Controlled synthesis of NiCo nanoalloys embedded in ordered porous carbon by a novel soft-template strategy. Carbon 67:260–272. https://doi.org/10.1016/j.carbon.2013.09.089

Stojmenović M, Momčilović M, Gavrilov N, Pašti IA, Mentus S, Jokić B, Babić B (2015) Incorporation of Pt, Ru and Pt-Ru nanoparticles into ordered mesoporous carbons for efficient oxygen reduction reaction in alkaline media. Electrochim Acta 153:130–139. https://doi.org/10.1016/j.electacta.2014.11.080

Duan L, Fu R, Xiao Z, Zhao Q, Wang J-Q, Chen S, Wan Y (2015) Activation of aryl chlorides in water under phase-transfer agent-free and ligand-free suzuki coupling by heterogeneous palladium supported on hybrid mesoporous carbon. ACS Catal 5:575–586. https://doi.org/10.1021/cs501356h

Fang Y, Huang X, Zeng Q, Wang L (2015) Metallic nanocrystallites-incorporated ordered mesoporous carbon as labels for a sensitive simultaneous multianalyte electrochemical immunoassay. Biosens Bioelectron 73:71–78. https://doi.org/10.1016/j.bios.2015.05.046

Zhang Y, Xing L-G, Chen X-W, Wang J-H (2015) Nano copper oxide-incorporated mesoporous carbon composite as multimode adsorbent for selective isolation of hemoglobin. ACS Appl Mater Interf 7:5116–5123. https://doi.org/10.1021/am508836m

Song L, Wang T, Xue H, Fan X, He J (2016) In-situ preparation of Pd incorporated ordered mesoporous carbon as efficient electrocatalyst for oxygen reduction reaction. Electrochim Acta 191:355–363. https://doi.org/10.1016/j.electacta.2016.01.083

Zhang L, Xiong Z, Chen Y, Peng L, Yu B, Gao X, Zhang R, Zhang L, Zhang W (2016) Soft-template synthesis of hydrophilic metallic zirconia nanoparticle-incorporated ordered mesoporous carbon composite and its application in phosphopeptide enrichment. RSC Adv 6:30014–30020. https://doi.org/10.1039/c6ra00326e

Cozzi PG (2004) Metal–salen schiff base complexes in catalysis: practical aspects. Chem Soc Rev 33:410–421. https://doi.org/10.1039/B307853C

Wezenberg SJ, Kleij AW (2008) Material applications for salen frameworks. Angew Chem Int Ed 47:2354–2364. https://doi.org/10.1002/anie.200702468

Whiteoak CJ, Salassa G, Kleij AW (2012) Recent advances with π-conjugated salen systems. Chem Soc Rev 41:622–631. https://doi.org/10.1039/c1cs15170c

Zhang G, Ni C, Liu L, Zhao G, Fina F, Irvine JTS (2015) Macro-mesoporous resorcinol–formaldehyde polymer resins as amorphous metal-free visible light photocatalysts. J Mater Chem A 3:15413–15419. https://doi.org/10.1039/C5TA03628C

Liu G, Li X, Lee J-W, Popov BN (2011) A review of the development of nitrogen-modified carbon-based catalysts for oxygen reduction at USC. Catal Sci Technol 1:207–217. https://doi.org/10.1039/c0cy00053a

van Wingerden B, van Veen JAR, Mensch CTJ (1988) An extended X-ray absorption fine structure study of heat-treated cobalt porphyrin catalysts supported on active carbon. J Chem Soc, Farad T I 84(1):65–74. https://doi.org/10.1039/F19888400065

Nallathambi V, Lee J-W, Kumaraguru SP, Wu G, Popov BN (2008) Development of high performance carbon composite catalyst for oxygen reduction reaction in PEM Proton Exchange Membrane fuel cells. J Power Sources 183:34–42. https://doi.org/10.1016/j.jpowsour.2008.05.020

Lee KT, Ji X, Rault M, Nazar LF (2009) Simple synthesis of graphitic ordered mesoporous carbon materials by a solid-state method using metal phthalocyanines. Angew Chem Int Ed 48:5661–5665. https://doi.org/10.1002/anie.200806208

Thambiliyagodage CJ, Hakat Y, Bakker MG (2016) One pot synthesis of carbon/Ni nanoparticle monolithic composites by nanocasting and their catalytic activity for 4-Nitrophenol reduction. Curr Catal 5:135–146. https://doi.org/10.2174/2211544705666160610093114

Srinivasu P, Islam A, P. Singh S, Han L, Kantam ML, Bhargava SK (2012) Highly efficient nanoporous graphitic carbon with tunable textural properties for dye-sensitized solar cells. J Mater Chem 22:20866–20869. https://doi.org/10.1039/c2jm33498d

Sails SR, Gardiner DJ, Bowden M, Savage J, Rodway D (1996) Monitoring the quality of diamond films using Raman spectra excited at 514.5nm and 633nm. Diamond Relat Mater 5:589–591

Wada N, Gaczl PJ, Solin SA (1980) “Diamond-Like” 3-fold coordinated amorphous Carbon. J Non-Cryst Solid 35&36:543–548

Ferrari AC, Robertson J (2000) Interpretation of Raman spectra of disordered and amorphous carbon. Phys Rev B 61(20):14095–14107. https://doi.org/10.1103/PhysRevB.61.14095

Pantea D, Darmstadt H, Kaliaguine S, Summchen L, Roy C (2001) Electrical conductivity of thermal carbon blacks influence of surface chemistry. Carbon 39:1147–1158

Soukup L, Gregora I, Jastrabik L, Konakova A (1992) Raman spectra and electrical conductivity of glassy carbon. Mater Sci Eng B11:355–357

Tuinstra F, Koenig JL (1970) Raman spectrum of graphite. J Chem Phys 53:1126–1131. https://doi.org/10.1063/1.1674108

Grob B, Schmid J, Ivleva NP, Niessner R (2012) Conductivity for soot sensing: possibilities and limitations. Anal Chem 84:3586–3592. https://doi.org/10.1021/ac203152z

Liu Y, Lin B, Li D, Zhang X, Sun Y, Yang H (2014) Magnetically-separable hierarchically porous carbon monoliths with partially graphitized structures as excellent adsorbents for dyes. J Porous Mat 21:933–938. https://doi.org/10.1007/s10934-014-9841-4

Liu Y, Lin B, Li D, Zhang X, Sun Y, Yang H (2014) Hierarchically porous graphitic carbon monoliths containing nickel nanoparticles as magnetically separable adsorbents for dyes. J Appl Poly Sci 132:41322. https://doi.org/10.1002/APP.41322. (41321 of 41327)

Liu Y, Lin B, Li D, Xu T, Zhang X, Sun Y, Yang H (2014) Synthesis and supercapacitive performance of hierarchically porous graphitic carbon monoliths containing cobalt nanoparticles. Micropor Mesopor Mater 200:245–252. https://doi.org/10.1016/j.micromeso.2014.08.058

Kim J, Lee J, Choi Y, Jo C (2014) Synthesis of hierarchical linearly assembled graphitic carbon nanoparticles via catalytic graphitization in SBA-15. Carbon 75:95–103. https://doi.org/10.1016/j.carbon.2014.03.039

Kicinski W, Bystrzejewski M, Rummeli MH, Gemming T (2014) Porous graphitic materials obtained from carbonization of organic xerogels doped with transition metal salts. Bull Mater Sci 37(1):141–150

Yang Z, Mokaya R (2008) Probing the effect of the carbonisation process on the textural properties and morphology of mesoporous carbons. Micropor Mesopor Mater 113:378–384. https://doi.org/10.1016/j.micromeso.2007.11.035

Chanda M, Rempel GL (1989) Selective sorption of uranyl and ferric ions on phenolic-type resins of glyoxyl-bis-2-hydroxyanil and salicylaldehyde-ehtylenenediamine. Reactive Polymers 11:71–82

Acknowledgements

The technical assistance of Dr. Ken Belmore in the collection and interpretation of the NMR spectra is greatly appreciated. The authors acknowledge the Central Analytical Facility (CAF) at the University of Alabama for support and technical assistance. A seed grant from the CAF at The University of Alabama is acknowledged, the required cost match for which was provided by the Bakker Research Gift fund. TVK acknowledges support from the Research Simulation program of the Office of Research at The University of Alabama.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

A number of the authors (M.G.B., T.V.K., K.H.S.) have a potential conflict of interest. They are co-inventors of work described in this and prior papers for which the University of Alabama has applied for multiple patents. A granted patent is licensed to a company that M.G.B. and T.V.K. have an ownership interest in.

Additional information

Online resources

This paper is accompanied by Online Resources consisting of: NMR spectra of E-salen and D-Salen ligands, and Ni-E-Salen complex. Tables of fits to XRD, Raman, and Electrical Conductivity and correlations to mesopore volumes. The original Raman spectra and X-Ray diffractograms.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Kotbagi, T.V., Shaughnessy, K.H., LeDoux, C. et al. Copolymerization of transition metal salen complexes and conversion into metal nanoparticles supported on hierarchically porous carbon monoliths: a one pot synthesis. J Sol-Gel Sci Technol 84, 258–273 (2017). https://doi.org/10.1007/s10971-017-4510-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-017-4510-0