Abstract

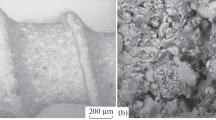

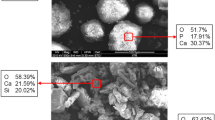

Coatings of biomedical implant surfaces by a bioactive calcium phosphate film render bioactivity to the implant surface and shorten the healing time. In this present study, calcium metaphosphate (CMP) sol was synthesized by sol–gel method and coated onto the titanium alloys (Ti-6Al-4V). CMP sol was first synthesized by reacting Ca(NO3)24H2O (Sigma–Aldrich 99%, USA) with (OC2H5)3P (Fluka 97%, Japan) in methyl alcohol. A stoichiometric Ca/P ratio of 0.5 was obtained by varying the amounts of the reactants. Sol was then coated on Ti-6Al-4V substrates by spin coating. The coated-specimens were then dried at 70 °C for 24 h, followed by a heat treatment at 650 °C for 1 h. Structural and chemical properties of the coatings were evaluated using XRD, SEM, and EPMA. The dissolution property of the coated-CMP layer was investigated by immersing the samples in the simulated body fluid (SBF) for 1, 3, 7 and 21 days. The concentration of Ca2+ released was measured using ICP. After heat treatment, SEM indicated a smooth and uniform CMP layer, with CMP grains of approximately 100 nm. The CMP phase was identified with δ-CMP (JCPDS #9-363). After immersion in SBF, coatings were observed to be roughened and porous. The concentration of Ca2+ in SBF was observed to increase over time, indicating continuous dissolution. The presence of titanium oxide phosphate compounds were also observed on CMP surfaces after immersion. It was thus concluded that the ability to control coating properties as well as the need for low heat treatment temperature offers advance for the use of CMP coating by sol–gel process on Ti-6Al-4V implant surfaces.

Similar content being viewed by others

References

Carlson SL, Rostlunt TR, Abrektsson B, Abrektsson T, Branemark PI (1986) Osseointegration of titanium implant. Acta Orthop Scand 57:285–289

Bardos DI (1990) Titanium and titanium alloys. In: William D (ed) Encyclopedia of medical and dental materials. Pergamon Press, Oxford, pp 360–365

Kasemo B (1983) Biocompatibility of titanium implant: surface science aspect. J Prosthet Dent 49:832–837

de Groot K, Geesink R, Klein CPAT, Serekian P (1984) Plasma sprayed coatings of hydroxyapatite. J Biomed Mater Res 21:1375–1387

Brown S (1984) The medical physiological potential of plasma-sprayed ceramic coatings. Thin Solid Films 119:127–139

Cook SD, Thomas KA, Kay JF, Jarcho M (1987) Interface mechanics and histology of titanium and hydroxyapatite-coated titanium for dental implant applications. Int J Oral Maxillofac Impl 2:15–22

Thomas KA, Kay JF, Cook SD, Jarcho M (1987) The effect of surface macrotexture and hydroxyapatite coating on the mechanical strengths and histologic profile of titanium implant materials. J Biomed Mater Res 21:1395–1414

Rivero DP, Fox J, Skipor AK, Urban RM, Galante JO (1988) Calcium phosphate-coated porous titanium implants for enhanced skeletal fixation. J Biomed Mater Res 22:191–201

Block MS, Delgado A, Fontenot MG (1990) The effect of diameter and length of hydroxyapatite-coated dental implants on ultimate pull-out force in dog alveolar bone. J Oral Maxillofac Surg 48:174–178

Filiaggi M, Pilliar RM, Coombs NA (1991) Characterization of the interface in the plasma-sprayed HA coating/Ti-6Al-4V implant system. J Biomed Mater Res 28:1211–1229

Whitehead RY, Lacefield WR, Lucas LC, Lemons JE (1992) Structural and bone strength evaluations of plasma-sprayed HA coatings. In: Proceedings of the fourth world biomaterials congress, Berlin, p 503

Kay JF (1992) Calcium phosphate coatings for dental implants. Dent Clin North Am 36:1–18

Ducheyne P, Cuckler JM (1992) Bioactive ceramic prosthetic coatings. Clin Orthop Relat Res 276:102–114

Corbridge DEC (1995) Phosphorous: an outline of its chemistry, biochemistry and uses. In: Corbridge D (ed) Studies in inorganic chemistry 20. Elsevier, Amsterdam, pp 224–235

Kanazawa T (ed) (1989) Inorganic phosphate materials. In: Materials science monographs, 52. Kodansha & Elsevier, Amsterdam, pp 221–246

Kim H-M, Takadama H, Miyaji F, Kokubo T, Nishiguchi S, Nakamura T (1998) In: Bioceramics 11. World Scientific, pp 655–658

Takadama H, Kim H-M, Miyaji F, Kokubo T, Nakamura T (1998) In: Bioceramics 11. World Scientific, pp 663–666

McIntosh AO, Jablonski WL (1956) X-ray diffraction powder patterns of the calcium phosphates. Anal Chem 28:1424–1427

Griffith EJ (1995) Phosphate fibers. Plenum Press, New York

Koo J, Kim SU, Yoon DS, No K, Bae BS (1997) Effect of heat treatment on formation of sol–gel (Pb, La)TiO3 films for optical application. J Biomed Mater Res 12:812–818

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oh, S., Han, MH., Im, WB. et al. Surface characterization and dissolution study of biodegradable calcium metaphosphate coated by sol–gel method. J Sol-Gel Sci Technol 53, 627–633 (2010). https://doi.org/10.1007/s10971-009-2141-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-009-2141-9