Abstract

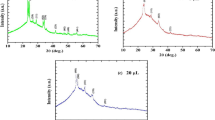

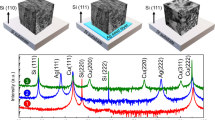

In this paper, the maximum thickness of crack-free yttrium-iron-garnet ferrite film was increased from 7 to 13 µm by layer by layer growth method. Also, the effect of a layer by layer growth method on films morphology, crystal structure and magnetic properties were investigated. X-ray diffraction θ–2θ revealed the orientation of crystal structure could be increased by the layer-by-layer growth method. Scanning electron microscopy and stylus profiler measurement showed the roughness and morphology of film surface were improved efficiently after using the layer-by-layer growth method. Magnetic hysteresis loops and FMR spectrum representing this layer-by-layer growth method could efficiently increase film magnetism and decrease FMR linewidth. Consequently, this innovative method of layer-by-layer growth efficiently provides a pathway to prepare excellent properties, tens of micron-thick, crack-free yttrium iron garnet films and creates unique significance in the electronics industry.

Similar content being viewed by others

References

M. Lang, M. Montazeri, M.C. Onbasli, X. Kou et al., Nano Lett. 14, 3459 (2014)

F.F.W.A. Wan, H.H. Jaafar, M.F. Ain, N.S. Abdullah, Z.A. Ahmad, J. Mater. Sci. Mater. Electron. 26(1), 1–11 (2014)

K. Ando, S. Watanabe, S. Mooser, E. Saitoh, H. Sirringhaus, Nat. Mater. 12, 622 (2013)

M. Veis, E. Lišková, R. Antoš et al., Thin Solid Films 519, 8041 (2011)

A.N. Hapishah, M. Hashim, M.M. Syazwan, I.R. Idza, N. Rodziah, J. Mater. Sci. Mater. Electron. 1–9 (2017)

I.V. Zavislyak, V.P. Sohatsky, M.A. Popov, G. Srinivasan, Phys. Rev. 87, 7 (2013)

M. Ezawa, J. Nanosci. Nanotechnol. 12, 386–395 (2012)

M. Pardavi-Horvath, J. Magn. Magn. Mater. 215, 171–183 (2000)

J.D. Bierlein, L.W. Hinderks, P.M. Richards, J. Appl. Phys. 38, 1232–1233 (1967)

H. Zheng, J.J. Zhou, J.X. Deng, P. Zheng et al., Mater. Lett. 123, 181 (2014)

V.G. Harris, A. Geiler, Y. Chen et al., J. Magn. Magn. Mater. 321, 2035 (2009)

C. Subramaniam, T. Yamada, K. Kobashi et al., Nat. Commun. 4, 2202 (2013)

V.G. Harris, IEEE Trans. Magn. 48, 1075 (2012)

I.I. Syvorotka, I.M. Syvorotka, S.B. Ubizskii, Solid State Phenom. 200, 250 (2013)

M. Huang, Z.C. Xu, Thin Solid Films 450, 324–328 (2004)

J.M. Robertson, J. Cryst. Growth 45, 233 (1978)

H. Buhay et al., IEEE Trans. Magn. 31, 3832 (1995)

A. Sposito et al., Opt. Mater. Express 3, 624 (2013)

A. Furuya et al., IEEE Trans. Magn. 37, 2407 (2001)

P.C. Dorsey et al., J. Appl. Phys. 81, 6884 (1997)

X.T. Zhou et al., J. Magn. Magn. Mater 320, 1817 (2008)

H. Zheng, P. Zheng, Q. Feng, J. Deng, Z. Ying, L. Zheng, Mater. Lett. 218, 241 (2018)

B. Bhoi, B. Sahu, N. Venkataramani et al., IEEE Trans. Magn. 51, 1 (2015)

Y. Krochenberger, K.S. Yun, T. Hatano et al., J. Appl. Phys. 106, 123911 (2009)

C.P. Hartwig, D.W. Readey, J. Appl. Phys. 41, 1351 (1970)

M.V. Schneider, Bell Labs Tech. J. 48, 1421 (1969)

P.C. Dorsey et al., J. Appl. Phys. 81, 6884–6689 (1997)

S.T. Shiue, C.H. Yang, R.S. Chu et al., Thin Solid Films 485, 169 (2005)

E. Popova, N. Keller, F. Gendron et al., J. Vac. Sci. Technol. 19, 2567 (2001)

C. Kittel, Phys. Rev. 73, 161 (1948)

D. Venkateswarlu, K.G. Padmalekha, S.V. Bhat, P.S.A. Kumar, IEEE Trans. Magn. 49, 3097 (2013)

Acknowledgements

This work is funded by Natural Science Foundation of Zhejiang Province of China (Grant Nos. LQ17A040002 and LY17F010021), the Key R&D Program of Zhejiang Province of China (No. 2017C01004), National Natural Science Foundation of China (Nos. 51702075, 11704092), the Nonprofit technology Research program of Zhejiang Province (No. 2017C31019).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zheng, H., Zheng, P., Wu, Q. et al. Tens of micron-thick, crack-free yttrium iron garnet films on a Gd3Ga5O12 substrate based on the layer by layer growth method. J Mater Sci: Mater Electron 29, 11790–11794 (2018). https://doi.org/10.1007/s10854-018-9278-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9278-7