Abstract

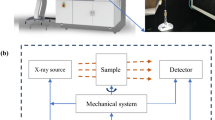

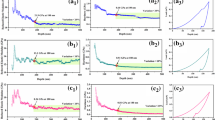

To accelerate development of new and improved wood adhesives for engineered wood products, the optimal adhesive penetration into wood needs to be better understood for specific products and applications. Adhesive penetration includes both flow of adhesives into wood micron-scale voids and infiltration into the polymer components of the wood cell wall layers. In this work, X-ray computed tomography (XCT) and X-ray fluorescence microscopy (XFM) were used to study adhesive flow and infiltration. Model wood–adhesive bondlines were made using loblolly pine (Pinus taeda) latewood substrates and bromine-substituted phenol formaldehyde (BrPF) resins with different weight-average molecular weights (MW). The Br substitution facilitated both qualitative and quantitative observations using XCT and XFM. The BrPF resin flow into wood was visualized using XCT volume reconstructions and quantified by calculating the weighted penetration (WP). Examination of the shape of the cured BrPF–air interface in longitudinal tracheid lumina revealed that capillary action often played a role in BrPF flow. XFM mapping revealed the pathways of BrPF infiltration into the wood cell walls, and the results were used to calculate BrPF cell wall weight percent gain (WPGCW) in individual wood cell walls. Both WP and WPGCW decreased with increasing BrPF MW. Additionally, the middle lamella had higher WPGCW than its neighboring secondary cell walls, and within a given bondline the WPGCW decreased with increasing distance of the cell from the bondline. The results provide new insights that are needed in the development of improved models to understand and predict wood–adhesive bondline performance.

Similar content being viewed by others

References

ASTM International (2007) ASTM adhesives standards, vol 1506. ASTM International, Conshohocken

Frihart CR (2005) Wood adhesion and adhesives. In: Rowell RM (ed) Handbook of wood chemistry and wood composites, 2nd edn. Taylor & Francis, New York, pp 215–278

Kamke FA, Lee JN (2007) Adhesive penetration in wood—a review. Wood Fiber Sci 39:205–220

Marra AA (1992) Technology of wood bonding: principles in practice. Springer, New York

Frihart CR (2009) Adhesive groups and how they relate to the durability of bonded wood. J Adhes Sci Technol 23:611–627

Nearn W (1965) Wood-adhesive interface relations. Off Dig Fed Soc Paint Technol 37:720–733

Nearn WT (1974) Application of the ultrastructure concept in industrial wood products research. Off Dig Fed Soc Paint Technol 6:285–293

Wimmer R, Kläusler O, Niemz P (2013) Water sorption mechanisms of commercial wood adhesive films. Wood Sci Technol 47:763–775

Glass SV, Zelinka SL (2010) Moisture relations and physical properties of wood. In: Wood handbook: wood as an engineering material, Centennial edn. General technical report FPL, GTR-190. U.S. Dept. of Agriculture, Forest Service, Forest Products Laboratory, Madison, pp 4.1–4.19

Konnerth J, Gindl W (2006) Mechanical characterisation of wood-adhesive interphase cell walls by nanoindentation. Holzforschung 60:429–433

Modzel G, Kamke FA, De Carlo F (2011) Comparative analysis of a wood: adhesive bondline. Wood Sci Technol 45:147–158

Gardner DJ, Blumentritt M, Wang L, Yildirim N (2015) Adhesion theories in wood adhesive bonding. In: Mittal KL (ed) Progress in adhesion and adhesives. Wiley, Hoboken, pp 125–168

Frazier CE, Ni J (1998) On the occurrence of network interpenetration in the wood–isocyanate adhesive interphase. Int J Adhes Adhes 18:81–87

Gindl W, Dessipri E, Wimmer R (2002) Using UV-microscopy to study diffusion of melamine–urea–formaldehyde resin in cell walls of spruce wood. Holzforschung 56:103–107

Furuno T, Imamura Y, Kajita H (2004) The modification of wood by treatment with low molecular weight phenol-formaldehyde resin: a properties enhancement with neutralized phenolic-resin and resin penetration into wood cell walls. Wood Sci Technol 37:349–361

Konnerth J, Harper D, Lee S-H et al (2008) Adhesive penetration of wood cell walls investigated by scanning thermal microscopy (SThM). Holzforschung 62:91–98

Xu D, Zhang Y, Zhou H et al (2016) Characterization of adhesive penetration in wood bond by means of scanning thermal microscopy (SThM). Holzforschung 70:323–330

Xing C, Riedl B, Cloutier A, Shaler SM (2005) Characterization of urea–formaldehyde resin penetration into medium density fiberboard fibers. Wood Sci Technol 39:374–384

Cyr P-L, Riedl B, Wang X-M (2008) Investigation of urea–melamine–formaldehyde (UMF) resin penetration in medium-density fiberboard (MDF) by high resolution confocal laser scanning microscopy. Holz Roh Werkst 66:129–134

Hunt CE, Jakes JE, Grigsby W (2010) Evaluation of adhesive penetration of wood fibre by nanoindentation and microscopy. In: BIOCOMP 2010; 10th Pacific Rim bio-based composites symposium, pp 216–226

Grigsby WJ, Thumm A (2012) Resin and wax distribution and mobility during medium density fibreboard manufacture. Eur J Wood Wood Prod 70:337–348

Wang X, Deng Y, Li Y et al (2016) In situ identification of the molecular-scale interactions of phenol-formaldehyde resin and wood cell walls using infrared nanospectroscopy. RSC Adv 6:76318–76324

Jakes JE, Gleber S-C, Vogt S et al (2013) New synchrotron-based technique to map adhesive infiltration in wood cell walls. In: Proceedings of 2013 annual meeting of the Adhesion Society, Daytona Beach Ocean, Resort Daytona Beach, FL, Daytona Beach, FL, USA, 3–6 Mar 2013, pp 1–3

Jakes JE, Hunt CG, Yelle DJ et al (2015) Synchrotron-based X-ray fluorescence microscopy in conjunction with nanoindentation to study molecular-scale interactions of phenol-formaldehyde in wood cell walls. ACS Appl Mater Interfaces 7:6584–6589

Plaza NZ (2017) Neutron scattering studies of nano-scale wood–water interactions. PhD dissertation, University of Wisconsin-Madison

Plaza NZ, Frihart CR, Hunt CG et al (2017) Small angle neutron scattering as a new tool to study moisture-induced swelling in the nanostructure of chemically modified wood cell walls. In: Hunt CG, Smith GD, Yan N (eds) Proceedings of the international conference on wood adhesives 2017. Forest Products Society, Peachtree Corners, GA

Evans PD, Morrison O, Senden TJ et al (2010) Visualization and numerical analysis of adhesive distribution in particleboard using X-ray micro-computed tomography. Int J Adhes Adhes 30:754–762

Paris JL, Kamke FA (2015) Quantitative wood-adhesive penetration with X-ray computed tomography. Int J Adhes Adhes 61:71–80

Hansen CM, Bjorkman A (1998) Ultrastructure of wood from a solubility parameter point of view. Holzforschung 52:335–344

Mantanis GI, Young RA, Rowell RM (1994) Swelling of wood. Part II. Swelling in organic liquids. Holzforschung 48:480–490

Gürsoy D, De CF, Xiao X (2014) TomoPy: a framework for the analysis of synchrotron tomographic data. J Synchrotron Radiat 21:118–1193

McKinley PE, Ching DJ, Kamke FA et al (2016) Micro X-ray computed tomography of adhesive bonds in wood. Wood Fiber Sci 48:2–16

Schmid B, Schindelin J, Cardona A et al (2010) A high-level 3D visualization API for Java and ImageJ. BMC Bioinformatics 11:274. https://doi.org/10.1186/1471-2105-11-274

Schindelin J, Arganda-Carreras I, Frise E et al (2012) Fiji: an open-source platform for biological-image analysis. Nat Methods 9:676–682

Vogt S (2003) MAPS: a set of software tools for analysis and visualization of 3D X-ray fluorescence data sets. J Phys IV 104:635–638

Paris JL, Kamke FA, Mbachu R, Gibson SK (2014) Phenol formaldehyde adhesives formulated for advanced X-ray imaging in wood-composite bondlines. J Mater Sci 49:580–591. https://doi.org/10.1007/s10853-013-7738-2

Paris JL, Kamke FA, Xiao X (2015) X-ray computed tomography of wood-adhesive bondlines: attenuation and phase-contrast effects. Wood Sci Technol 49:1185–1208

Dunky M (2003) Adhesives in the wood industry. In: Pizzi A, Mittal K (eds) Handbook of adhesive technology, revised and expanded, 2nd edn. CRC Press, Boca Raton, pp 887–956

Hass P, Wittel FK, Mendoza M et al (2012) Adhesive penetration in beech wood: experiments. Wood Sci Technol 46:243–256

Sernek M, Resnik J, Kamke FA (1999) Penetration of liquid urea–formaldehyde adhesive into beech wood. Wood Fiber Sci 31:41–48

Tarkow H, Feist WC, Southerland CF (1966) Interaction of wood with polymeric materials—penetration versus molecular size. For Prod J 16:61–65

Thybring EE, Kymäläinen M, Rautkari L (2018) Experimental techniques for characterising water in wood covering the range from dry to fully water-saturated. Wood Sci Technol 52:297–329

Hunt C, O’Dell J, Jakes J et al (2015) Wood as polar size exclusion chromatography media: implications to adhesive performance. For Prod J 65:9–14

Gabrielli CP, Kamke FA (2009) Phenol-formaldehyde impregnation of densified wood for improved dimensional stability. Wood Sci Technol 44:95–104

Stamm AJ, Seborg RM (1936) Minimizing wood shrinkage and swelling. Ind Eng Chem 28:1164–1169

Rowell RM, Petterson R, Tshabalala MA (2013) Cell wall chemistry. In: Rowell RM (ed) Handbook of wood chemistry and wood composites, 2nd edn. Taylor & Francis, New York, pp 33–72

Laborie M-PG, Salmen L, Frazier CE (2006) A morphological study of the wood/phenol-formaldehyde adhesive interphase. J Adhes Sci Technol 20:729–741

Norimoto M (2001) Chemical modification of wood. In: Hon DN-S, Shirashi N (eds) Wood and cellulose chemistry, 2nd edn. Marcel Dekker, New York, pp 573–598

Jakes JE, Frihart CR, Hunt CG et al (2017) Integrating multi-scale studies of adhesive penetration into wood. In: Hunt CG, Smith GD, Yan N (eds) Proceedings of the international conference on wood adhesives 2017. Forest Products Society, Peachtree Corners, GA

Acknowledgements

This research used resources of the Advanced Photon Source, a US Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jakes, J.E., Frihart, C.R., Hunt, C.G. et al. X-ray methods to observe and quantify adhesive penetration into wood. J Mater Sci 54, 705–718 (2019). https://doi.org/10.1007/s10853-018-2783-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2783-5