Abstract

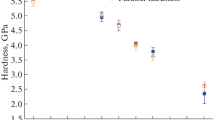

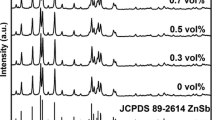

For thermoelectric generators, the individual thermoelectric elements are subjected to significant stresses under in-service conditions, due to thermal cycles, transients, and gradients, as well as thermal expansion mismatch and externally applied mechanical stresses. Most thermoelectric materials are brittle, possessing a low fracture toughness that is typically no more than 1.5 MPa m1/2 and is often less than 0.5 MPa m1/2. The combination of the stresses encountered in the device application environment and the materials’ low fracture toughness constitute a severe challenge to the viability of thermoelectric generators. The addition of silicon carbide nanoparticles (SiCNP) may provide a route to improving the fracture toughness for a wide range of thermoelectric materials. This study examines the mechanical properties, including elastic modulus, hardness, and fracture toughness for 0–4 vol% SiCNP incorporated into Mg2Si thermoelectric matrices.

Similar content being viewed by others

References

Schmidt RD, Case ED, Giles J et al (2012) Room-temperature mechanical properties and slow crack growth behavior of Mg2Si thermoelectric materials. J Electron Mater 41:1210–1216. doi:10.1007/s11664-011-1879-3

Eilertsen J, Subramanian MA, Kruzic JJ (2013) Fracture toughness of Co4Sb12 and in 0.1Co4Sb12 thermoelectric skutterudites evaluated by three methods. J Alloys Compd 552:492–498. doi:10.1016/j.jallcom.2012.11.066

Ren F, Case ED, Timm EJ, Schock HJ (2008) Hardness as a function of composition for n-type LAST thermoelectric material. J Alloys Compd 455:340–345. doi:10.1016/j.jallcom.2007.01.086

Ni JE, Case ED, Khabir KN et al (2010) Room temperature Young’s modulus, shear modulus, Poisson’s ratio and hardness of PbTe–PbS thermoelectric materials. Mater Sci Eng, B 170:58–66. doi:10.1016/j.mseb.2010.02.026

Wiederhorn SM (1969) Fracture surface energy of glass. J Am Ceram Soc 52:99–105. doi:10.1111/j.1151-2916.1969.tb13350.x

Launey ME, Ritchie RO (2009) On the fracture toughness of advanced materials. Adv Mater 21:2103–2110. doi:10.1002/adma.200803322

Foulk JW III, Cannon RRM, Johnson GGC et al (2007) A micromechanical basis for partitioning the evolution of grain bridging in brittle materials. J Mech Phys Solids 55:719–743. doi:10.1016/j.jmps.2006.10.009

Becher PF (1991) Microstructural design of toughened ceramics. J Am Ceram Soc 74:255–269. doi:10.1111/j.1151-2916.1991.tb06872.x

Ritchie R (1999) Mechanisms of fatigue-crack propagation in ductile and brittle solids. Int J Fract 100:55–83. doi:10.1023/A:1018655917051

Case ED (2012) Thermo-mechanical properties of thermoelectric materials. In: Rowe DM (ed) thermoelectrics and its energy harvesting. modules, systems, and applications. CRC Press, Boca Raton, p 581

Case ED (2012) Thermal fatigue and waste heat recovery via thermoelectrics. J Electron Mater 41:1811–1819. doi:10.1007/s11664-012-2083-9

Lathabai S, Rodel J, Lawn BR (1991) Cyclic fatigue from frictional degradation at bridging grains in alumina. J Am Ceram Soc 74:1340–1348. doi:10.1111/j.1151-2916.1991.tb04109.x

Bhowmick S, Meléndez-Martínez JJ, Lawn BR (2007) Bulk silicon is susceptible to fatigue. Appl Phys Lett 91:201902. doi:10.1063/1.2801390

Bhowmick S, Cha H, Jung Y-G, Lawn BR (2009) Fatigue and debris generation at indentation-induced cracks in silicon. Acta Mater 57:582–589. doi:10.1016/j.actamat.2008.10.006

Knehans R, Steinbrech R (1982) Memory effect of crack resistance during slow crack growth in notched Al2O3 bend specimens. J Mater Sci Lett 1:327–329. doi:10.1007/BF00726477

Pérez-Rigueiro J, Pastor J, Llorca J et al (1998) Revisiting the mechanical behavior of alumina/silicon carbide nanocomposites. Acta Mater 46:5399–5411. doi:10.1016/S1359-6454(98)00193-1

Parchovianský M, Galusek D, Sedláček J et al (2013) Microstructure and mechanical properties of hot pressed Al2O3/SiC nanocomposites. J Eur Ceram Soc 33:2291–2298. doi:10.1016/j.jeurceramsoc.2013.01.024

Zhao L-D, Zhang B-P, Li J-F et al (2008) Thermoelectric and mechanical properties of nano-SiC-dispersed Bi2Te3 fabricated by mechanical alloying and spark plasma sintering. J Alloys Compd 455:259–264. doi:10.1016/j.jallcom.2007.01.015

Tani J, Kido H (2005) Thermoelectric properties of bi-doped MgSi semiconductors. Phys B Condens Matter 364:218–224. doi:10.1016/j.physb.2005.04.017

Hayatsu Y, Iida T, Sakamoto T et al (2012) Fabrication of large sintered pellets of Sb-doped n-type Mg2Si using a plasma activated sintering method. J Solid State Chem 193:161–165. doi:10.1016/j.jssc.2012.07.008

Tani J, Kido H (2008) Thermoelectric properties of Al-doped Mg2Si1 − xSnx (x ≦ 0.1). J Alloys Compd 466:335–340. doi:10.1016/j.jallcom.2007.11.029

Meng QS, Fan WH, Chen RX, Munir ZA (2011) Thermoelectric properties of Sc- and Y-doped Mg2Si prepared by field-activated and pressure-assisted reactive sintering. J Alloys Compd 509:7922–7926. doi:10.1016/j.jallcom.2011.05.033

Muthiah S, Pulikkotil J, Srivastava AK et al (2013) Conducting grain boundaries enhancing thermoelectric performance in doped Mg2Si. Appl Phys Lett 103:053901. doi:10.1063/1.4816802

Tani J, Kido H (2007) Thermoelectric properties of Sb-doped Mg2Si semiconductors. Intermetallics 15:1202–1207. doi:10.1016/j.intermet.2007.02.009

Li J-F, Liu J (2006) Effect of nano-SiC dispersion on thermoelectric properties of Bi 2 Te 3 polycrystals. Phys Status Solidi 203:3768–3773. doi:10.1002/pssa.200622011

Li J, Tan Q, Li J-F et al (2013) BiSbTe-based nanocomposites with high ZT: the effect of SiC nanodispersion on thermoelectric properties. Adv Funct Mater 23:4317–4323. doi:10.1002/adfm.201300146

Li Z-Y, Li J-F, Zhao W-Y et al (2014) PbTe-based thermoelectric nanocomposites with reduced thermal conductivity by SiC nanodispersion. Appl Phys Lett 104:113905. doi:10.1063/1.4869220

Alfa-Aesar material safety data sheet, magnesium silicide. http://www.alfa.com/content/msds/USA/45518.pdf

Pilchak AL, Ren F, Case ED et al (2007) Characterization of dry milled powders of LAST (lead–antimony–silver–tellurium) thermoelectric material. Philos Mag 87:4567–4591. doi:10.1080/14786430701566044

Schreiber E, Soga N (1966) Elastic constants of silicon carbide. J Am Ceram Soc 49:342. doi:10.1111/j.1151-2916.1966.tb13278.x

Schmidt RD, Ni JE, Case ED et al (2010) Room temperature Young’s modulus, shear modulus, and Poisson’s ratio of Ce0.9Fe3.5Co0.5Sb12 and Co0.95Pd0.05Te0.05Sb3 skutterudite materials. J Alloys Compd 504:303–309. doi:10.1016/j.jallcom.2010.06.003

Migliori A, Sarrao JL (1997) Resonant ultrasound spectroscopy: applications to physics, materials measurements, and nondestructive evaluation. Wiley, New York

Wachtman JB, Cannon WR, Matthewson MJ (2009) Mechanical properties of ceramics, 2nd edn. Wiley, Hoboken

ASTM-Standard-E112-13 (2014) Standard test methods for determining average grain size. ASTM Vol 0301 Met Mech Testing; Elev Low Temp Tests; Metallogr. doi: 10.1520/E0112-13

Whitten W, Chung P, Danielson G (1965) Elastic constants and lattice vibration frequencies of Mg2Si. J Phys Chem Solids 26:49–56. doi:10.1016/0022-3697(65)90071-5

Durand MA (1936) The temperature variation of the elastic moduli of NaCl, KCl and MgO. Phys Rev 50:449–455. doi:10.1103/PhysRev.50.449

Schmidt RD, Case ED, Ni JE et al (2013) High-temperature elastic moduli of thermoelectric SnTe1 ± x − y SiC nanoparticulate composites. J Mater Sci 48:8244–8258. doi:10.1007/s10853-013-7637-6

Hashin Z (1962) The elastic moduli of heterogeneous materials. J Appl Mech 29:143–150. doi:10.1115/1.3636446

Bedolla E, Lemus-Ruiz J, Contreras A (2012) Synthesis and characterization of Mg-AZ91/AlN composites. Mater Des 38:91–98. doi:10.1016/j.matdes.2012.02.001

Couturier R, Ducret D, Merle P et al (1997) Elaboration and characterization of a metal matrix composite: Al/AlN. J Eur Ceram Soc 17:1861–1866

Carnahan RD (1968) Elastic properties of silicon carbide. J Am Ceram Soc 51:223–224. doi:10.1111/j.1151-2916.1968.tb11877.x

Rice RW (1998) Porosity of Ceramics. Marcel Dekker, New York

Anderson OL, Andreatch P (1966) Pressure derivatives of elastic constants of single-crystal MgO at 23° and −195.8°C. J Am Ceram Soc 49:404–409. doi:10.1111/j.1151-2916.1966.tb15405.x

Bogardus EH (1965) Third-order elastic constants of Ge, MgO, and fused SiO2. J Appl Phys 36:2504. doi:10.1063/1.1714520

Simmons G, Wang H (1971) Single crystal elastic constants and calculated aggregate properties: a handbook, 2nd edn. Press, Cambridge, Massachusetts, The M.I.T

Schmidt RD, Case ED, Lehr GJ, Morelli DT (2013) Room temperature mechanical properties of polycrystalline YbAl3, a promising low temperature thermoelectric material. Intermetallics 35:15–24. doi:10.1016/j.intermet.2012.11.019

Ni JE, Ren F, Case ED, Timm EJ (2009) Porosity dependence of elastic moduli in LAST (Lead–antimony–silver–tellurium) thermoelectric materials. Mater Chem Phys 118:459–466. doi:10.1016/j.matchemphys.2009.08.018

Acknowledgements

The authors acknowledge the financial support of the Department of Energy, Revolutionary Materials for Solid State Energy Conversion Center, an Energy Frontiers Research Center funded by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences under Award number DE-SC0001054.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schmidt, R.D., Fan, X., Case, E.D. et al. Mechanical properties of Mg2Si thermoelectric materials with the addition of 0–4 vol% silicon carbide nanoparticles (SiCNP). J Mater Sci 50, 4034–4046 (2015). https://doi.org/10.1007/s10853-015-8960-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-8960-x