Abstract

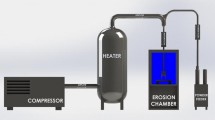

In order to study the effects of particle properties on the solid particle erosion mechanisms of brittle bulk materials, six target materials were tested using two different powders (alumina and glass) at velocities ranging from 25 to 75 m/s. Following in depth characterizations of the targets and of the particles before and after testing, it was found that lateral fracture was the dominant material removal mechanism as predicted by the elasto-plastic theory of erosion. In the case of glass powder, for which the hardness of the particle is lower than the hardness of the target, particle deformation and fragmentation were found to be important factors explaining lower erosion rates. The higher than predicted velocity exponents point toward a velocity-dependent damage accumulation mechanism which was found to be correlated to target yield pressure (H 3 /E 2). Although damage accumulation seems to be necessary for material removal when using both powders, the effect is more pronounced for the softer glass powder because of kinetic energy dissipation through different means.

Similar content being viewed by others

References

Hutchings IM (1992) Tribology: friction and wear of engineering materials. CRC Press, London

Finnie I (1958) Proceedings of the 3rd US National Congress of Applied Mechanics, New York, 527

Hutchings IM (1981) Wear 70:269

Lawn BR, Fuller ER, Wiederhorn SM (1976) J Am Ceram Soc 59:193

Hockey BJ, Wiederhorn SM, Johnson H (1978) Clays Clay Miner 3:379

Hockey BJ, Wiederhorn SM (1979) Proceedings of the Annual Industrial Pollution Conference, Philadelphia, 26

Wiederhorn SM, Lawn BR (1979) J Am Ceram Soc 62:66

Slikkerveer PJ, Bouten PCP, in’t Veld FH, Scholten H (1998) Wear 217:237

Evans AG, Gulden ME, Rosenblatts M (1978) Proceedings of the Royal Society of London, Series A (Mathematical and Physical Sciences) 361: 343

Bitter JGA (1963) Wear 6:5

Wheeler DW, Wood RJK (1999) Wear 225–229:523

Basak AK, Fan JM, Wang J, Mathew P (2010) Wear 269:269. doi:10.1016/j.wear.2010.04.006

Hutchings IM (1992) Key Eng Mater 71:75

Lawn BR, Evans AG (1977) J Mater Sci 12:2195. doi:10.1007/BF00552240

Lawn BR, Evans AG, Marshall DB (1980) J Am Ceram Soc 63:574

Marshall DB, Lawn BR, Evans AG (1982) J Am Ceram Soc 65:561

Wiederhorn SM, Hockey BJ, Ruff AW, Ives LK (1980) Dimens NBS 64:20

Buijs M (1994) J Am Ceram Soc 77:1676

ASTM-G76 (2007) Standard specification for carbon structural steel. ASTM International, West Conshohocken

Bousser E, Benkahoul M, Martinu L, Klemberg-Sapieha JE (2008) Surf Coat Technol 203:776. doi:10.1016/j.surfcoat.2008.08.012

Tabakoff W (1992) Surf Coat Technol 52:65

Immarigeon J-P, Chow D, Parameswaran VR, Au P, Saari H, Koul AK (1997) Adv Perform Mater 4:371

Wada S (1992) Key Eng Mater 71:57

Srinivasan S, Scattergood RO (1988) Wear 128:139. doi:10.1016/0043-1648(88)90180-9

Murugesh L, Scattergood RO (1990) Wear 141:115. doi:10.1016/0043-1648(90)90196-h

Murugesh L, Scattergood RO (1991) J Mater Sci 26:5456. doi:10.1007/BF00553644

Shipway PH, Hutchings IM (1991) Wear 149:85. doi:10.1016/0043-1648(91)90366-3

Shipway PH, Hutchings IM (1996) Wear 193:105

Curkovic L, Kumic I, Grilec K (2011) Ceram Int 37:29. doi:10.1016/j.ceramint.2010.08.029

Ruff AW, Ives LK (1975) Wear 35:195

Oliver WC, Pharr GM (1992) J Mater Res 7:1564

Yang R, Zhang T, Jiang P, Bai Y (2008) Appl Phys Lett 92:261903. doi:10.1063/1.2944138

Lawn BR, Cook RF (2012) J Mater Sci 47:1. doi:10.1007/s10853-011-5865-1

Pharr GM (1998) Mater Sci Eng A A253:151

Morris DJ, Cook RF (2005) Int J Fract 136:237. doi:10.1007/s10704-005-6034-9

Morris DJ, Vodnick AM, Cook RF (2005) Int J Fract 136:265. doi:10.1007/s10704-005-6033-x

Jang J-I, Pharr GM (2008) Acta Mater 56:4458. doi:10.1016/j.actamat.2008.05.005

Leonardi A, Furgiuele F, Wood RJK, Syngellakis S (2010) Eng Fract Mech 77:264. doi:10.1016/j.engfracmech.2009.08.003

Zhang T, Feng Y, Yang R, Jiang P (2010) Scripta Mater 62:199. doi:10.1016/j.scriptamat.2009.10.025

Anstis GR, Chantikul P, Lawn BR, Marshall DB (1981) J Am Ceram Soc 64:533

de Boer GBJ, de Weerd C, Thoenes D, Goossens HWJ (1987) Part Charact 4:14

Palik ED (1985) Handbook of optical constants of solids. Academic Press Inc, Orlando

Chicot D, Pertuz A, Roudet F, Staia MH, Lesage J (2004) Mater Sci Technol 20:877. doi:10.1179/026708304225017427

Wiederhorn SM, Hockey BJ (1983) J Mater Sci 18:766. doi:10.1007/BF00745575

Bull SJ (2006) J Phys D (Appl Phys) 39:1626

Chen J, Bull SJ (2006) J Mater Res 21:2617. doi:10.1557/jmr.2006.0323

Johnson KL (1987) Contact mechanics. Cambridge University Press, Cambridge

Tsui TY, Pharr GM, Oliver WC, et al. (1995) Thin films: stresses and mechanical properties V. Symposium, 28 Nov–2 Dec. 1994 Mater Res Soc, Pittsburgh

Leyland A, Matthews A (2000) Wear 246:1. doi:10.1016/s0043-1648(00)00488-9

Hassani S, Bielawski M, Beres W, Martinu L, Balazinski M, Klemberg-Sapieha JE (2008) Surf Coat Technol 203:204. doi:10.1016/j.surfcoat.2008.08.050

Acknowledgements

The authors gratefully acknowledge the support of the Fonds de recherche du Québéc—Nature et Technologies (FQRNT), the Consortium for Research and Innovation in Aerospace in Québec (CRIAQ) and the Natural Sciences and Engineering Research Council (NSERC) of Canada. The authors also wish to thank Francis Turcot for his invaluable technical expertise.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bousser, E., Martinu, L. & Klemberg-Sapieha, J.E. Effect of erodent properties on the solid particle erosion mechanisms of brittle materials. J Mater Sci 48, 5543–5558 (2013). https://doi.org/10.1007/s10853-013-7349-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7349-y