Abstract

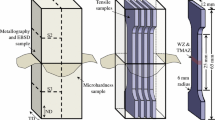

Ti–5Al–5V–5Mo–3Cr (Ti-5553) sheets were welded using a Nd: YAG laser system and Ti–6Al–4V filler wire. The effect of joint gap on weld geometry, defects, microstructure, and hardness was investigated. Fully penetrated welds up to a joint gap of 0.5 mm were produced. The two main defects observed were porosity and underfill. The addition of filler wire reduced underfill but increased porosity, especially at large joint gaps. The fusion zone (FZ) microstructure at low joint gaps consisted of retained β with a dendritic morphology. At a joint gap of 0.3 mm, regions of orthorhombic α″ martensite were observed in the weld zone which increased in proportion as the joint gap increased from a volume percentage of 4.9% at 0.3 mm to a volume percentage of 44% at 0.5 mm. Despite the differences in microstructure with increasing joint gap, the FZ hardness remained relatively constant for all joint gaps evaluated.

Similar content being viewed by others

References

Boyer RR, Cotton JD, Slattery KT, Weber GR (2008) Adv Mater Process 166:25

Rendigs K-H (2004) Titanium products used at AIRBUS. Paper presented at the Ti-2003 Science and Technology, Weinheim, Germany

Lütjering G, Williams JC (2003) Titanium. Springer, Berlin, Heidelberg

Boyer RR, Briggs RD (2005) J Mater Eng Perform 14(6):681

Fanning JC, Boyer RR (2005) J Mater Eng Perform 14(6):788

Veeck S, Lee D, Boyer R, Briggs R (2005) J Adv Mater 37(4):40

Moiseyev VN (2006) Titanium alloys: Russian aircraft and aerospace applications. CRC Press, Boca Raton

Buddery A, Kelly P, Drennan J, Dargusch M (2011) J Mater Sci 46:2726. doi:10.1007/s10853-010-5145-5

Huang H-H, Lin S-C, Lee T-H, Chen C-C (2005) J Mater Sci 40:789. doi:10.1007/s10853-005-6325-6

Li X, Xie J, Zhou Y (2005) J Mater Sci 40:3437. doi:10.1007/s10853-005-0447-8

Shi Y, Zhong F, Li X, Gong S, Chen L (2007) J Mater Sci 42:6651. doi:10.1007/s10853-007-1524-y

Vaidya WV, Horstmann M, Ventzke V, Petrovski B, Kocak M, Kocik R, Tempus G (2010) J Mater Sci 45:6242. doi:10.1007/s10853-010-4719-6

Cao X, Jahazi M (2009) Opt Lasers Eng 47:1231

Dilthey U, Fuest D, Scheller W (1995) Opt Quant Electron 27:1181

DebRoy T, David SA (1995) Rev Mod Phys 67(1):85

Steen WM (1998) Laser material processing, 2nd edn. Springer, London

Cao X, Debaecker G, Poirier E, Marya S, Cuddy J, Birur A, Wanjara P (2009) Effect of joint gap in Nd: YAG laser welded Ti–6Al–4V (paper no. 157). Paper presented at the ICALEO, Orlando, FL

Mitchell DR (1982) Weld J 61:157s

Khaled T (1994) J Mater Eng Perform 3(3):419

Cao X, Wallace W, Poon C, Immarigeon J-P (2003) Mater Manuf Process 20(5):1

Cao X, Debaecker G, Poirier E, Marya S, Cuddy J, Birur A, Wanjara P (2009) Effect of joint gap on Nd: YAG laser welded Ti–6Al–4V (paper P157). Paper presented at the ICALEO 2009, Orlando, FL, Nov 2–5, 2009

Short AB (2009) Mater Sci Technol 25(3):309

Yang YK, Kou S (2010) Sci Technol Weld Join 15(1):15

Clement N, Lenain A, Jacques PJ (2007) J Miner Met Mater Soc 59(1):50

Moiseev VN, Polyak EV, Sokolova AY (1975) Met Sci Heat Treat 17(8):687

Liu PS, Hou KH, Baeslack WA III, Hurley J (1993) In: Eylon D, Boyer R, Koss DA (eds) Beta titanium alloys in the 1990’s: proceedings of a symposium on beta titanium alloys sponsored by the titanium committee of TMS, Denver, CO, 1993. TMS (The Minerals, Metals & Materials Society), pp. 383–393

Liu PS, Baeslack WA, Hurley J (1994) Weld J 73(7)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shariff, T., Cao, X., Chromik, R.R. et al. Effect of joint gap on the quality of laser beam welded near-β Ti-5553 alloy with the addition of Ti–6Al–4V filler wire. J Mater Sci 47, 866–875 (2012). https://doi.org/10.1007/s10853-011-5866-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5866-0