Abstract

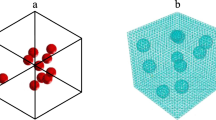

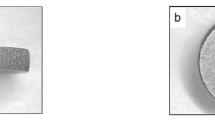

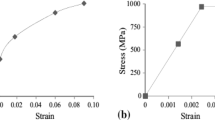

This article develops a constitutive model for the yield stress of SiC reinforced aluminum alloy composites based on the modified shear lag model, Eshelby’s equivalent inclusion approach, and Weibull statistics. The SiC particle debonding and cracking during deformation have been incorporated into the model. It has been shown that the yield stress of the composites increases as the volume fraction and aspect ratio of the SiC particles increase, while it decreases as the size of the SiC particles increases. Four types of aluminum alloys, including pure aluminum, Al–Mg–Si alloy, Al–Cu–Mg alloy, and Al–Zn–Mg alloy, have been chosen as the matrix materials to verify the model accuracy. The comparisons between the model predictions and the experimental counterparts indicate that the present model predictions agree much better with the experimental data than the traditional modified shear lag model predictions. The present model indicates that particle failure has important effect on the yield stress of the SiC reinforced aluminum alloy composites.

Similar content being viewed by others

References

Cox HL (1952) Br J Appl Phys 3:72

Kelly A (1973) Strong solids. Clarendon Press, Oxford, p 147

Nardone VC (1987) Scr Metall 21:1313

Nardone VC, Prewo KM (1986) Scr Metall 20:43

Taya M, Arsenault RJ (1987) Scr Metall 21:349

Arsenault RJ, Fisher RM (1983) Scr Metall 17:67

Arsenault RJ, Shi N (1986) Mater Sci Eng 81:175

Miller WS, Humphreys FJ (1991) Scr Metall Mater 25:33

González C, Llora J (1996) Scr Mater 35:91

Lewis CA, Withers PJ (1995) Acta Metall Mater 43:3685

Llorca J (1995) Acta Metall Mater 43:181

Maire E, Wilkinson DS, Embury JD, Fougeres R (1997) Acta Mater 45:5261

Withers PJ, Stobbs WM, Pedersen OB (1989) Acta Metall 37:3061

McElro TJ, Szkopiak ZC (1972) Inter Metall Rev 17:175

Sekine H, Chen R (1995) Composites 26:183

Ashby MF (1970) Philos Mag 21:399

Liews CA, Stobbs WM, Withers PJ (1993) Mater Sci Eng A 171:1

Tohgo K, Weng GJ (1994) Trans ASME J Eng Mater Technol 116:414

Lee HK (2001) Comp Mech 27:504

Shimbo M, Naka M, Okamoto I (1989) J Mater Sci Lett 8:663

Brown LM, Clarke DR (1975) Acta Metall 23:821

Song M, Li X, Chen KH (2007) Metall Mater Trans A 38:638

Hong S, Kim H, Huh D, Suryanarayana C, Chun BS (2003) Mater Sci Eng A 347:198

Arsenault RJ, Wang L, Feng CR (1991) Acta Metall Mater 39:47

Dutta I, Bourell DL (1989) Mater Sci Eng A 112:67

Nieh TG, Karlak RF (1984) Scr Metall 18:25

Papazian JM (1988) Metall Trans A 19:2945

Varma VK, Mahajan YR, Kutumnarao VV (1997) Scr Mater 37:485

Acknowledgements

This work was supported by National Natural Science Foundation of China (50801068), PhD Programs Foundation of Ministry of Education of China (200805331044), and Hunan Postdoctoral Scientific Program (2008RS4020). One of the authors would also like to thank the support from Chinese Postdoctoral Science Foundation (200801345, 20070410303).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, M., He, Y. & Fang, S. Yield stress of SiC reinforced aluminum alloy composites. J Mater Sci 45, 4097–4110 (2010). https://doi.org/10.1007/s10853-010-4498-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4498-0