Abstract

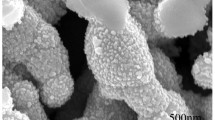

Recent literature is reviewed on a phase inversion process followed by sintering, used to fabricate ceramic hollow fibres (HFs) as precursors to micro-tubular solid oxide fuel cells (MT-SOFCs) with sub-millimetre inner diameters. These aimed to address the outstanding technological and economic issues that have delayed mass production of SOFCs, by increasing electrode surface areas per unit volume relative to planar structures, increasing power outputs per unit volume/mass, facilitating sealing at high temperatures, and decreasing fabrication costs per kW. Some recent experimental results are presented of the effects of temperature, hydrogen flow rate, thermal cycling and time of NiO reduction with H2 on the subsequent performance of 25 mm long H2|Ni–CGO|CGO|LSCF|air MT-SOFCs, incorporating cerium–gadolinium oxide (CGO) electrolyte, nickel anodes and lanthanum strontium cobalt ferrite–CGO (LSCF–CGO) cermet cathodes, designed to operate at 500–600 °C. Maximum power densities of 3–5.5 kW m−2 were achieved as the temperature was increased from 550–600 °C. The co-extruded MT-SOFCs were resilient to three thermal cycles when heated to operating temperature in ca. 5 min. Their performance was intimately related to the reduction time, suggesting slow conversion of the NiO to Ni within the fabricated anodes. At constant cell voltage, mass transport limited current densities increased from ca. 11 to ca. 13.5 kA m−2 as hydrogen flow rates were increased from 15 to 60 cm3 min−1, though had residual NiO in the anode been fully reduced, current densities would have been significantly greater.

Similar content being viewed by others

References

Grande FD, Thursfield A, Kanawka K, Droushiotis N, Doraswami U, Li K, Kelsall GH, Metcalfe IS (2009) Solid State Ion 180(11–13):800

Droushiotis N, Doraswami U, Kanawka K, Kelsall GH, Li K (2009) Solid State Ion 180(17–19):1091

Howe KS, Thompson GJ, Kendall K (2011) J Power Sources 196:1677

Droushiotis N, Doraswami U, Kelsall GH (2009) Trans Electrochem Soc 25(2):1241

Brett DJL, Atkinson A, Brandon NP, Skinner SJ (2008) Chem Soc Rev 37:1568

Othman MdHD, Droushiotis N, Wu Z, Kelsall GH, Li K (2011) J Power Sources 196:5035

Othman MdHD (2011) High performance micro-tubular solid oxide fuel cell, PhD Thesis, Imperial College London

Doraswami U, Droushiotis N, Kelsall GH (2010) Electrochim Acta 55:3766

Doraswami U (2010) Modelling of micro-tubular hollow fibre solid oxide fuel cells. PhD Thesis, Imperial College London

Droushiotis N, Othman MdHD, Doraswami U, Wu Z, Kelsall GH, Li K (2009) Electrochem Commun 11:1799

Droushiotis N, Doraswami U, Kelsall GH (2009) Trans Electrochem Soc 25(2):665

Othman MdHD, Wu Z, Droushiotis N, Doraswami U, Kelsall GH, Li K (2010) J Membr Sci 351:196

Droushiotis N, Doraswami U, Ivey D, Othman MdHD, Li K, Kelsall GH (2010) Electrochem Commun 12:792

Othman MdHD, Droushiotis N, Wu Z, Kelsall GH, Li K (2011) Advanced materials 23:2480

Droushiotis ND (2011) Fabrication and characterization of hollow fibre micro-tubular solid oxide fuel cells. PhD Thesis, Imperial College London

Othman MdHD, Droushiotis N, Wu Z, Kanawka K, Kelsall GH, Li K (2010) J Membr Sci 365(1–2):382

Othman MdHD, Wu Z, Droushiotis N, Kelsall GH, Li K (2010) J Membr Sci 360(1–2):410

Doraswami U, Shearing P, Droushiotis N, Li K, Brandon NP, Kelsall GH (2009) Solid State Ion 192:494

Yang NT, Tan XY, Ma ZF (2008) J Power Sources 183:14

Yang C, Li W, Zhang S, Bi L, Peng R, Chen C, Liu W (2009) J Power Sources 187:90

Jin C, Liu J, Li LH, Bai YH (2009) J Membr Sci 341:233

Zhang X, Lin B, Ling Y, Dong Y, Meng G, Liu X (2010) Int J Hydrog Energy 35:8654

Yang C, Jin C, Chen F (2010) Electrochim Acta 56:80

Zhao L, Zhang X, Hea B, Liu B, Xia C (2011) J Power Sources 196:962

Kendall K (2009) Int J Appl Ceram Technol 7:1

Suzuki T, Yamaguchi T, Fujishiro Y, Awano M (2006) J Power Sources 160:73

Suzuki T, Funahashi Y, Yamaguchi T, Fujishiro Y, Awano M (2008) J Alloys Compd 451:632

NIST-JANAF (1998) Thermochemical tables, 4th edn. J Phys Chem Ref Data Monogr 9:1–1951. http://webbook.nist.gov/chemistry/. Accessed 24 July 2011

Song HY, Wadsworth ME (eds) (1979) Rate processes in extractive metallurgy. Plenum, New York, pp 303

Szekely J, Evans JW (1971) Chem Eng Sci 26:1901

Szekely J, Evans JW (1973) Chem Eng Sci 28:1975

Acknowledgments

The authors thank the UK Engineering and Physical Sciences Research Council and the British Council for studentships for ND and UD, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Droushiotis, N., Doraswami, U., Kelsall, G.H. et al. Micro-tubular solid oxide fuel cells fabricated from hollow fibres. J Appl Electrochem 41, 1005–1012 (2011). https://doi.org/10.1007/s10800-011-0334-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-011-0334-8